Finished plastic product with wood-like grains and forming device thereof

A molding device and technology for finished products, applied in the field of plastic products and their molding devices, can solve the problems of inconsistent use requirements, insufficient thickness, inability to form multi-colored imitation wood grains, etc., and achieve good texture and simulation. , the effect of increasing competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

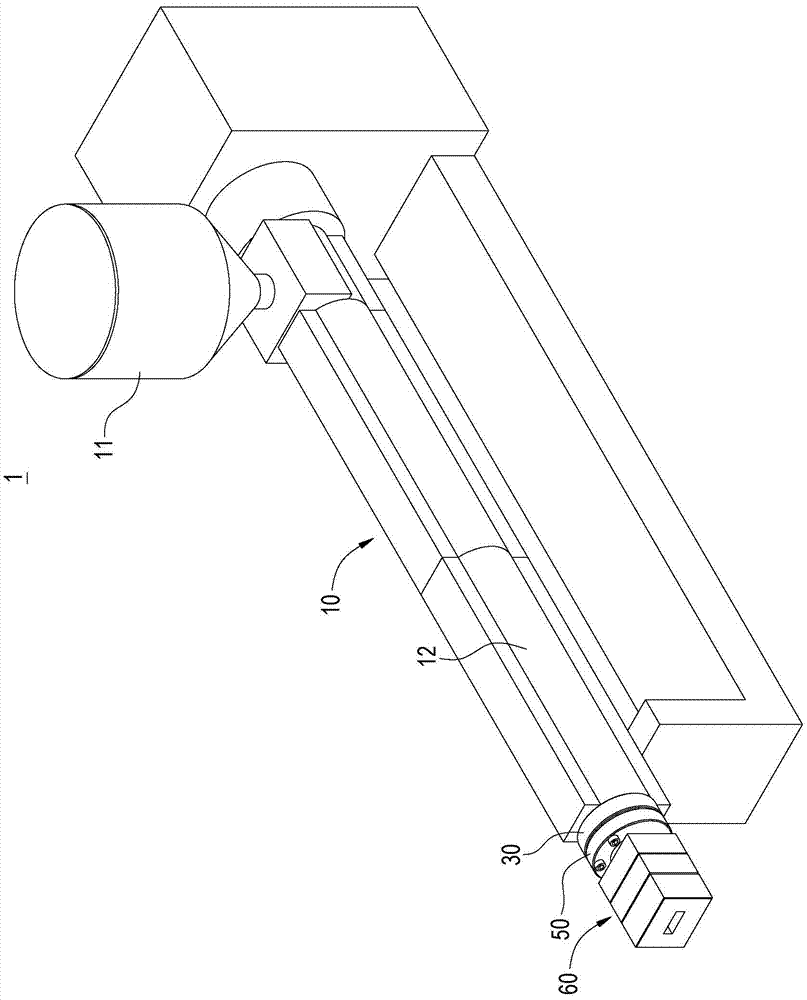

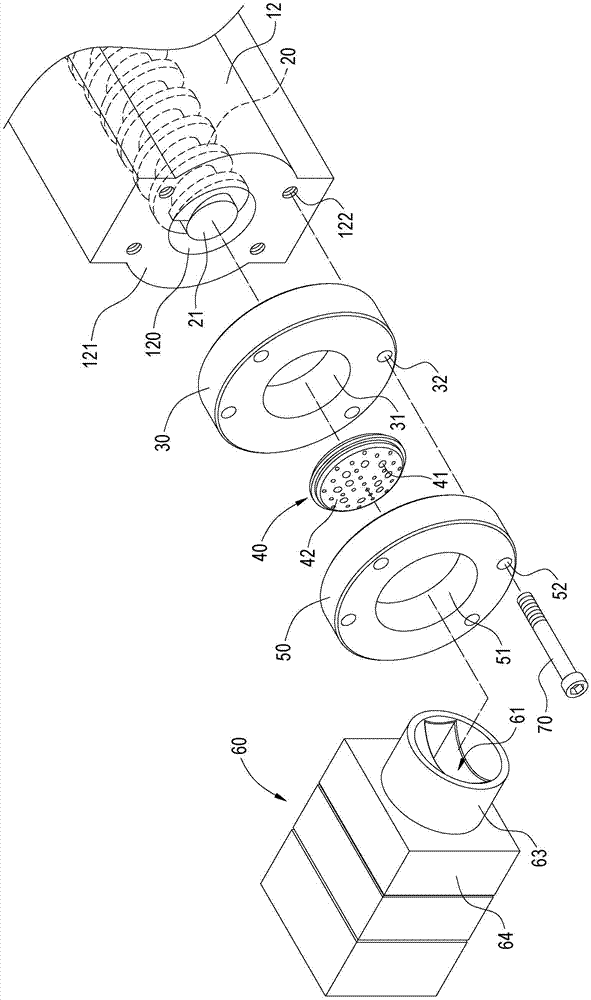

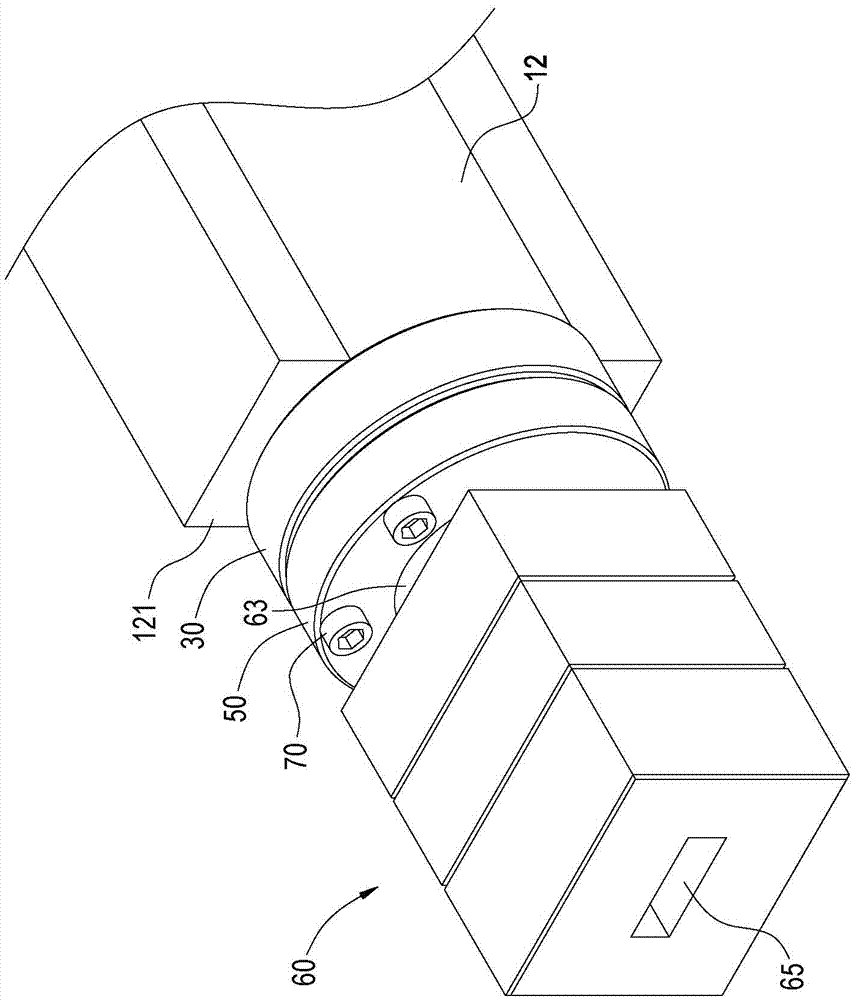

[0063] Please refer to Figure 1 to Figure 4 , are respectively the three-dimensional appearance schematic diagram, partial three-dimensional exploded view, partial three-dimensional view and partial combined sectional view of the molding device of the plastic product with imitation wood grain of the present invention. The molding device 1 of the plastic product with imitation wood grain of the present invention comprises an extruder body 10 , a screw 20 , a collar 30 , a honeycomb cover 40 , a fixing ring 50 and a molding die 60 . The screw 20 is installed on the extruder body 10 ; the honeycomb cover 40 is clamped between the collar 30 and the fixing ring 50 , and fixed on one s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com