Mounting method capable of resisting vortex-induced vibration and damping vibration of fan tower tube

A technology of vortex-induced vibration and installation method, which is applied in the direction of wind power engine, machine/engine, wind power motor combination, etc., which can solve the problems of hidden dangers, falling off of the tower, displacement of the tower section, etc., so as to reduce the vibration amplitude and clear the design concept , Reduce the effect of vortex induced vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

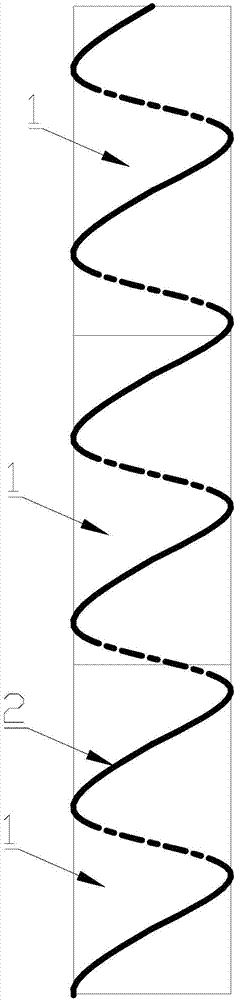

[0062] Such as figure 1 , Figure 5 to Figure 7 As shown, in this embodiment, a vortex-induced vibration damper for installation of a fan tower is introduced. The fan tower includes a multi-section tower section 1 installed sequentially from bottom to top; from the top of the top tower section 1 to the There is a shock-absorbing rope 2 extending downward, and the shock-absorbing rope 2 is spirally arranged around the outer wall of the tower tube. fixed.

[0063] This embodiment also introduces an installation method for anti-vortex-induced vibration and shock absorption of a wind turbine tower. The wind turbine tower includes multi-section tower sections 1 installed sequentially from bottom to top; Install at least one shock-absorbing rope 2 on the outer periphery of the top tower section, the shock-absorbing rope 2 is arranged around the outer wall of the tower in a spiral shape, and the lower end of the shock-absorbing rope 2 is fixedly connected to the bottom of the tower...

Embodiment 2

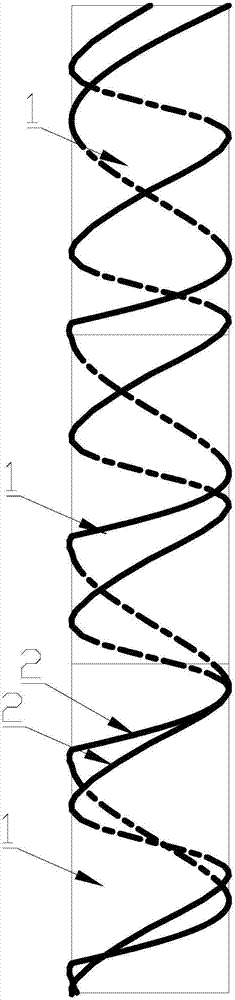

[0079] The difference between this embodiment and the first embodiment above is that: figure 2 As shown, a plurality of shock absorbing ropes 2 are installed at equal intervals from the top outer circumference of the top tower section 1, and each shock absorbing rope 2 is arranged spirally around the outer wall of the tower, and each spiral shock absorbing rope 2 Equally spaced and extending in the same shape, the lower ends of the shock absorbing ropes 2 and the outer circumference of the bottom of the lowest tower section 1 are installed and fixed at equal intervals.

[0080] Preferably, in this embodiment, the outer circumference of the tower is coiled with a plurality of equally spaced, helical shock-absorbing ropes 2, and each shock-absorbing rope 2 is distributed on the outer circumference of the tower at equal intervals, and the adjacent shock-absorbing The distances between the ropes 2 are set equally. By increasing the number of shock-absorbing ropes wound around th...

Embodiment 3

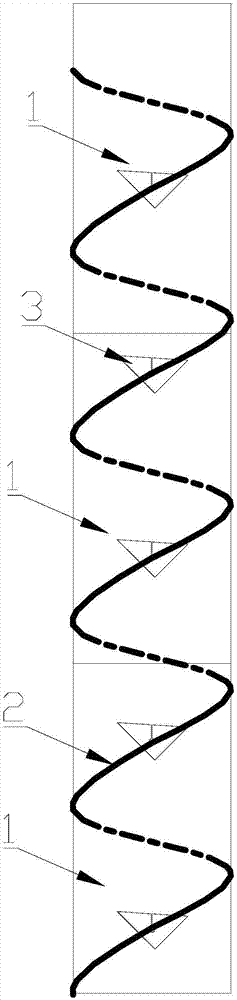

[0082] The difference between this embodiment and the first and second embodiments above is that: image 3 As shown, a plurality of auxiliary shock-absorbing parts 3 are threaded on the shock-absorbing rope 2, and the auxiliary shock-absorbing parts 3 are made of a plate, and the middle part of the plate is provided with a mounting hole 7 for the shock-absorbing rope to pass through, so that each auxiliary The shock-absorbing elements 3 are mounted on the shock-absorbing rope 2 at equal intervals.

[0083] By arranging a plurality of auxiliary shock absorbers pierced on the shock absorbing rope, the airflow around the tower can further change the flow direction under the action of the auxiliary shock absorbers, so that the impact force of the airflow around the tower on the tower can be further improved. The reduction effectively reduces the vibration amplitude of the tower and further improves the anti-vortex-induced vibration effect during the installation of the tower.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com