Quick connection mechanism

A quick connection and connector technology, applied in the direction of connecting components, mechanical equipment, quick-action fasteners, etc., can solve the problems of time-consuming and labor-intensive installation and disassembly, slow installation process, time-consuming and labor-intensive problems, and achieve fast and convenient disassembly and high installation efficiency , the effect of uniform load distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

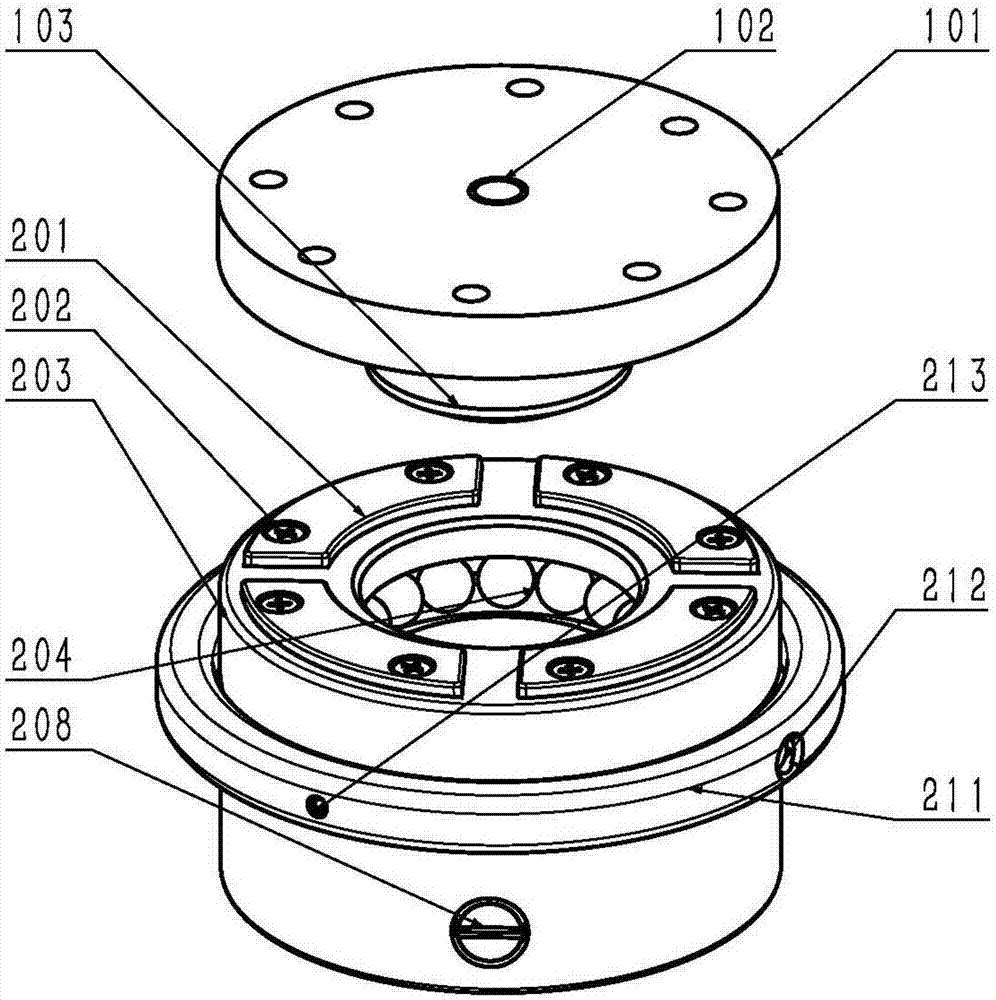

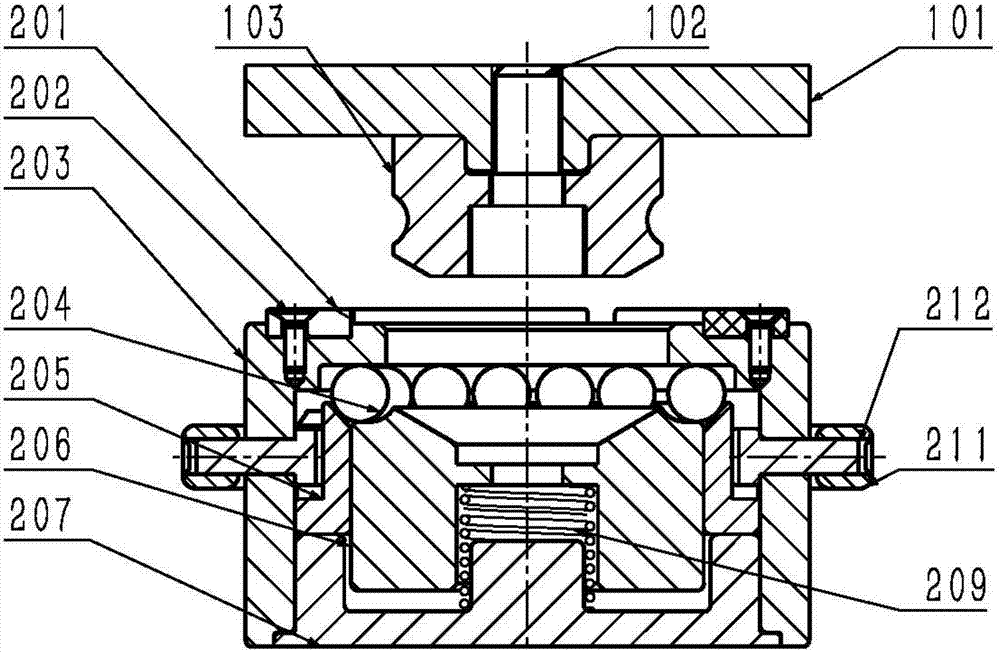

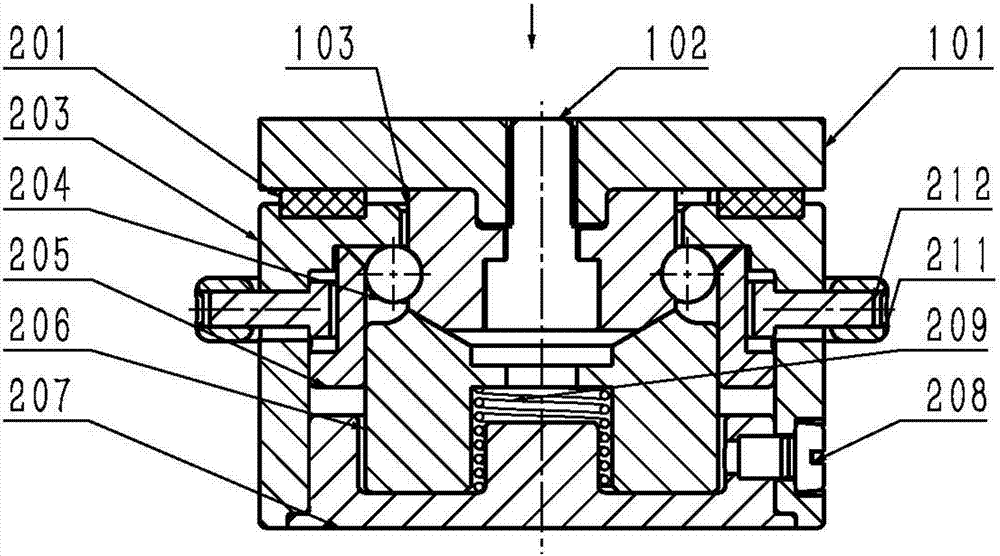

[0038] Such as Figures 1 to 4A quick connection mechanism shown includes a connecting head 1 and a locking assembly 2. The connecting head 1 includes a connecting plate 101 and a locking head 103 connected to each other. The locking head 103 is cylindrical, and its side wall is provided with a ring Groove C, the locking assembly 2 includes an outer casing 203, a positioning ball 204, a locking ring 205, a limit ring 206 and a fixed block 207; the outer casing 203 is a cylindrical metal sleeve, and the upper opening of the outer casing 203 is semi-open structure, the middle position of the upper port is provided with a through hole just for the lock head 103 to pass through, the lower port is o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com