Worm wheel gear tooth axial center measuring device and measuring method thereof

A technology of worm gear teeth and distance measuring device, which is applied to measuring devices, mechanical measuring devices, and mechanical devices, etc., can solve the problems of inaccurate quantification of assembly matching data, unqualified worm gears, hidden dangers of products, etc., so as to improve the efficiency of the assembly process. , The effect of reducing the cost of combination and improving the efficiency of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

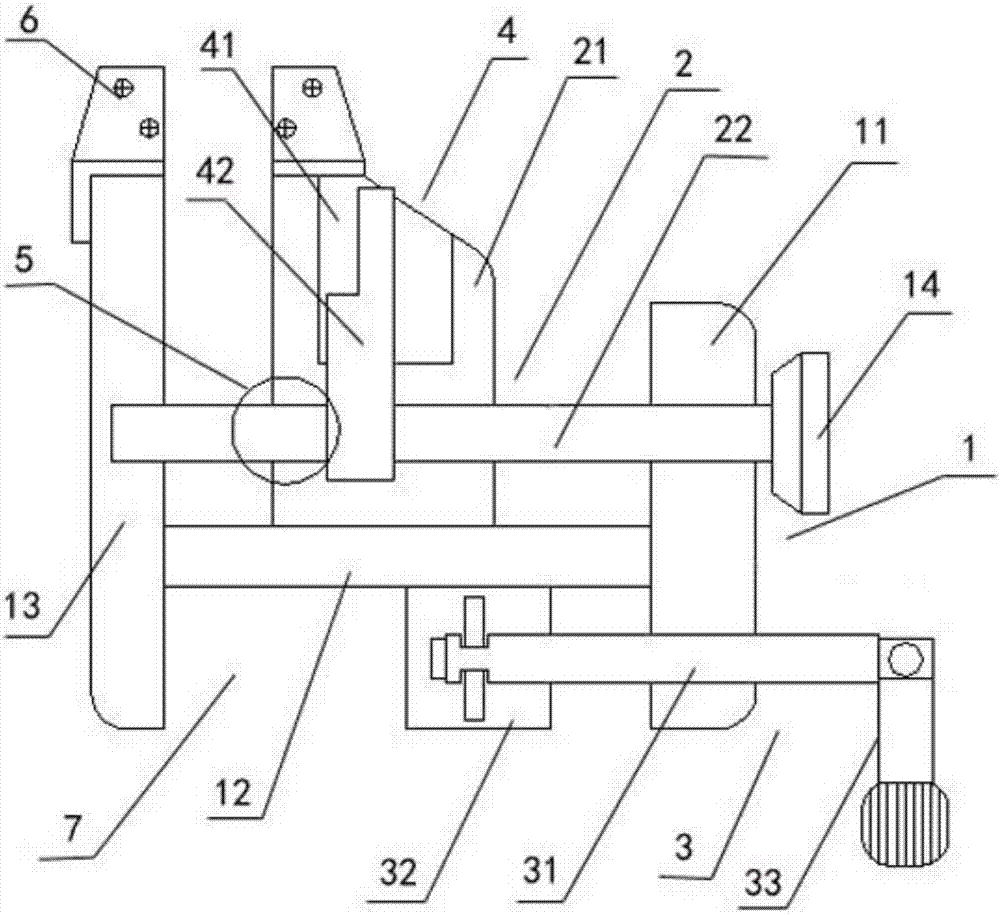

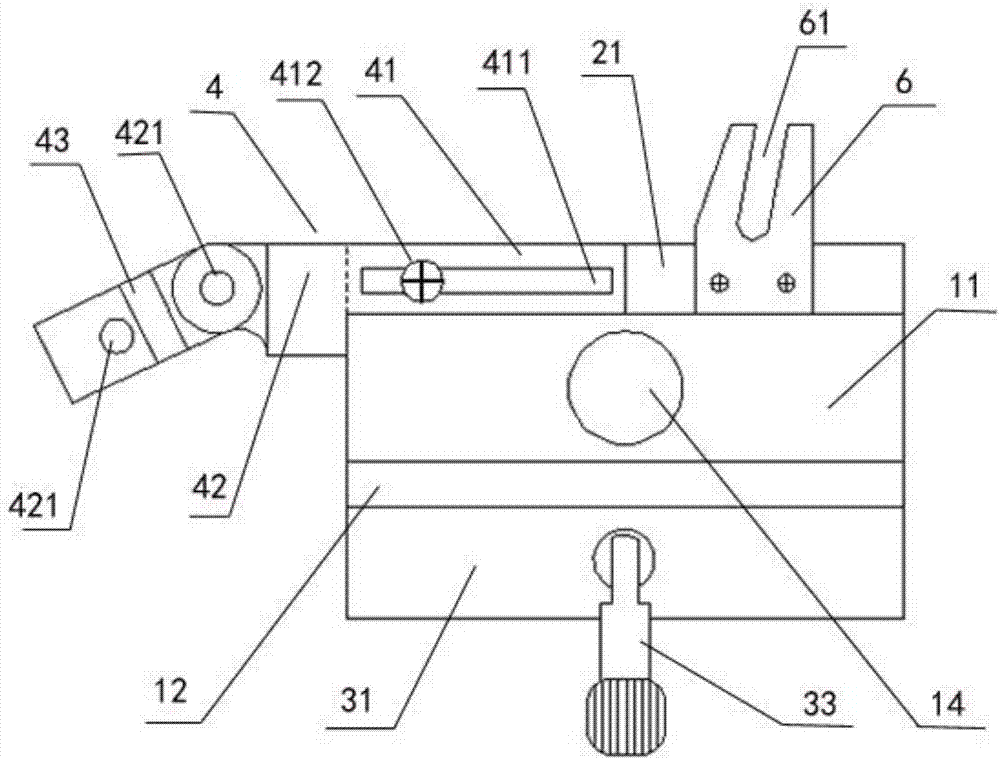

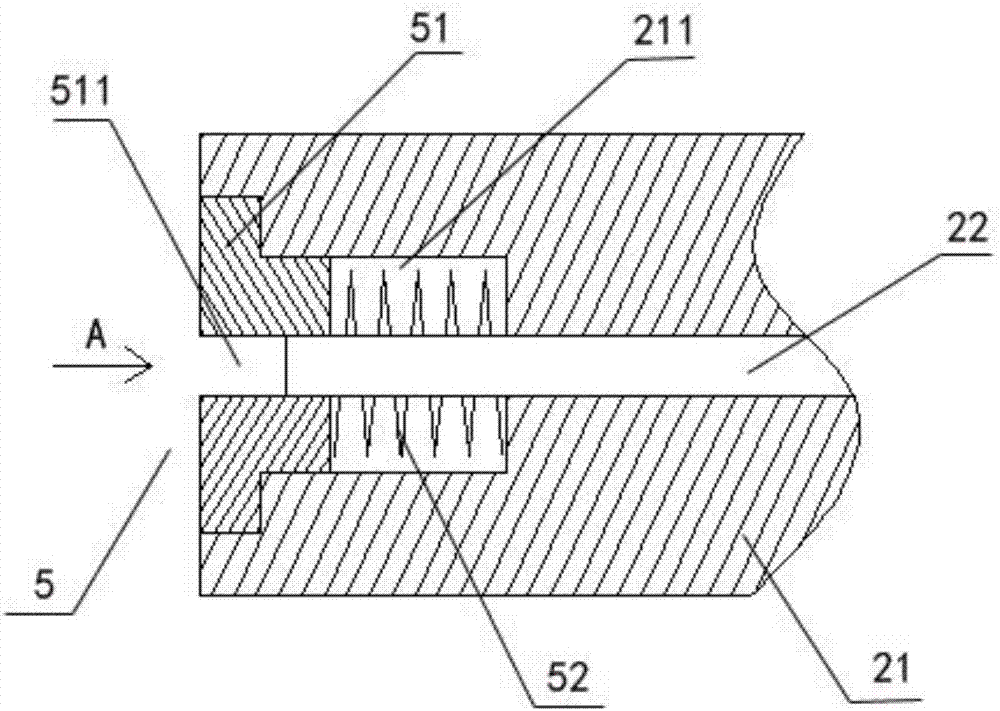

[0033] Such as figure 1 and 4 As shown, a worm gear gear axial centering device includes a bracket 1 , a sliding mechanism 2 , a clamping mechanism 3 , a distance measuring device 9 , and a dial gauge 8 . The distance measuring device 9 can be preferably a digital caliper, which is convenient for accuracy and flexibility of measurement. The dial indicator 8 can be preferably a bell type dial indicator. The sliding mechanism 2 and the clamping mechanism 3 are installed on the upper end and the lower end of the bracket 1 respectively. The distance measuring device 9 and the dial indicator 8 are installed on the sliding mechanism 2 . The sliding mechanism 2 can drive the movement of the distance measuring device 9 and the dial indicator 8 for simultaneous measurement. The distance measuring device 9 can measure the axial position of the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com