Laser measuring head device with variable measuring directions, and application method thereof

A technology of laser measuring head and measuring direction, which is applied in the direction of measuring devices, optical devices, instruments, etc., and can solve the problems of high cost of the measuring head shell, inapplicability, and influence on the measurement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described below in conjunction with drawings and embodiments.

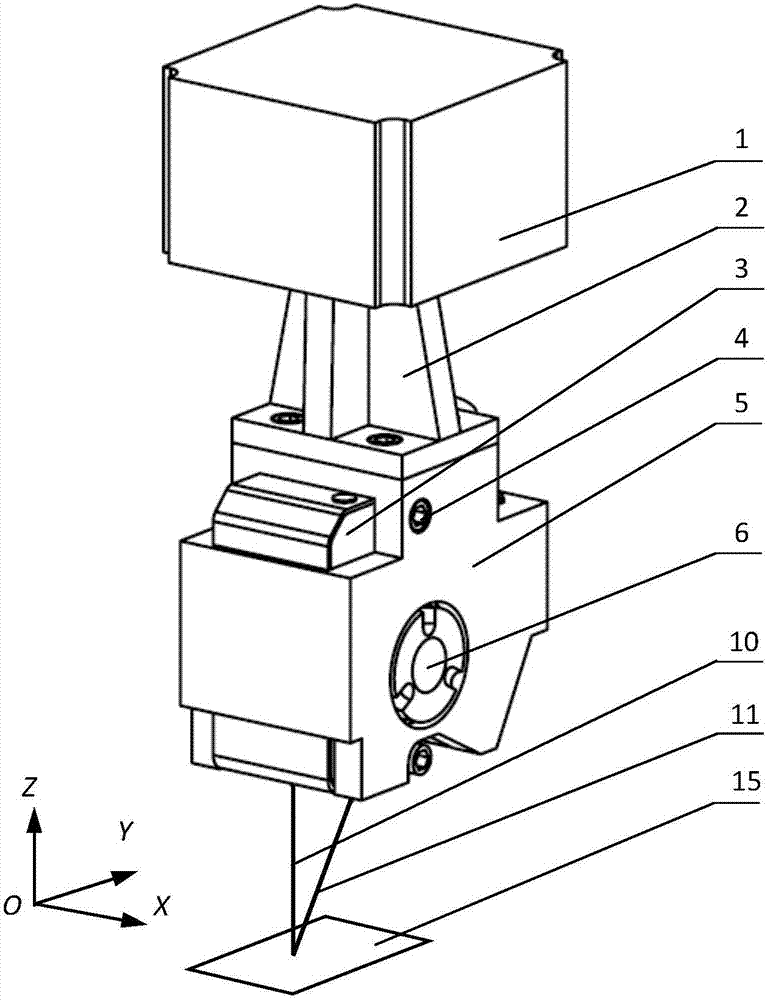

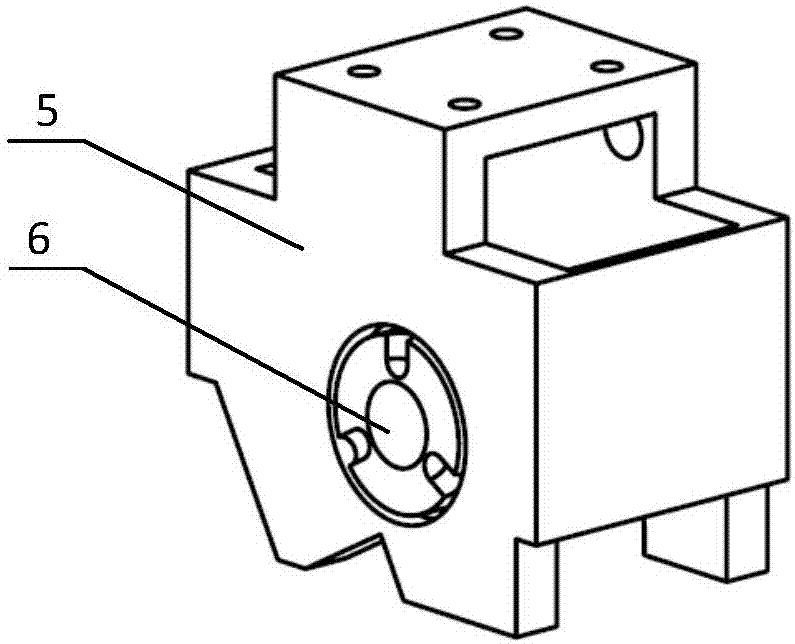

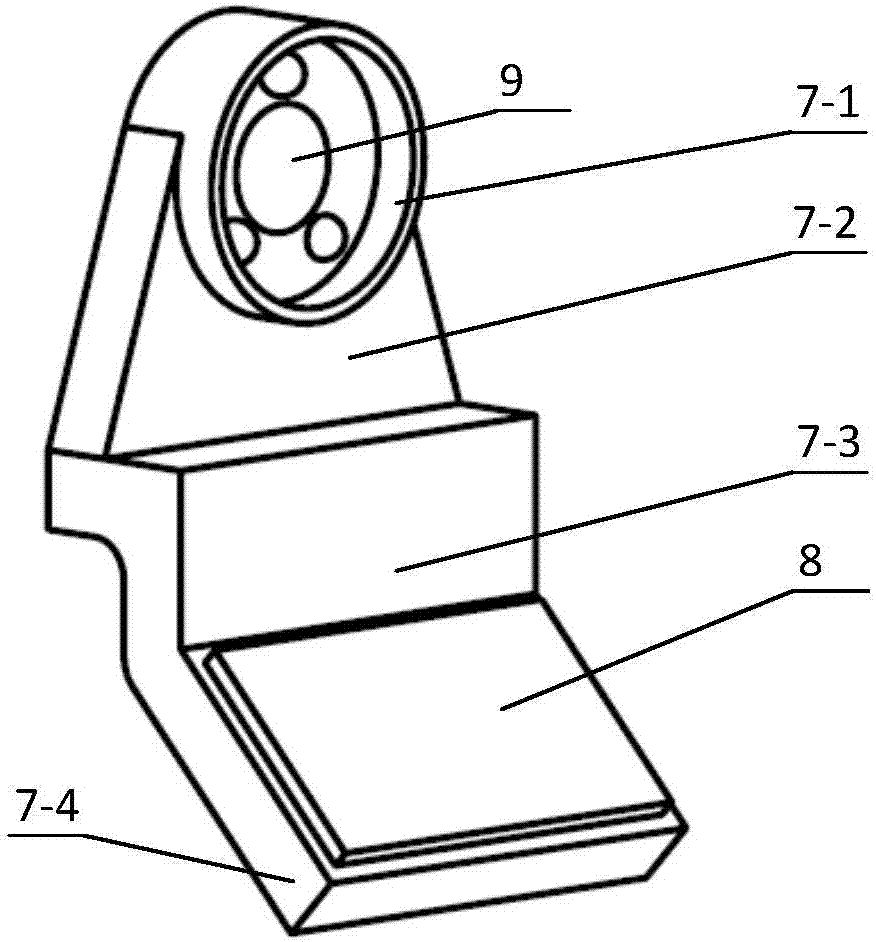

[0061] Such as figure 1 , 2 , 3, 4, 5, 7 and 9, the laser measuring head device with variable measuring direction, including connecting seat 2, laser measuring head 3, screw 4, measuring head shell 5, cylindrical magnet 6, X-direction mirror frame 7 , the first plane mirror 8, the first cylindrical iron block 9, the Y-direction mirror frame 10, the second plane mirror 11 and the second cylindrical iron block 12.

[0062] Such as figure 1 and 2 As shown, the upper end face of the connection seat 2 is fixed to the lower end of the vertical axis 1 of the coordinate measuring machine, and the lower end face is fixed to the upper end face of the probe housing 5 by screws 4 . The laser probe 3 is fixed inside the probe housing 5 by screws 4 . The laser measuring head 3 adopts a point-type laser displacement sensor. Take the X-axis of the three-coordinate measuring machi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap