A waste gas treatment machine

A technology of waste gas treatment and gas collection chamber, which is applied in the direction of smoke and dust removal, separation of dispersed particles, chemical instruments and methods, etc. It can solve the problems of bulky waste gas treatment equipment, high cost of use, and high price, and achieve simple structure and low manufacturing cost. And the effect of low maintenance cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

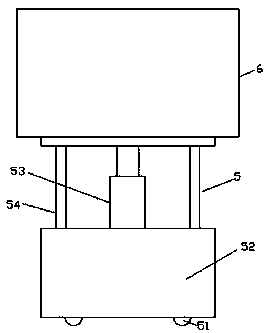

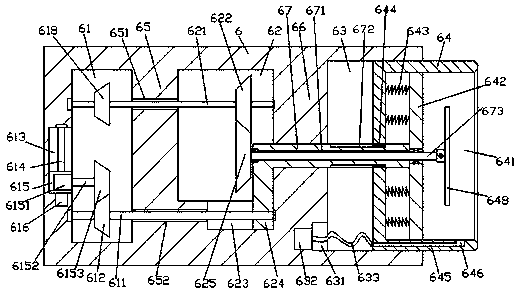

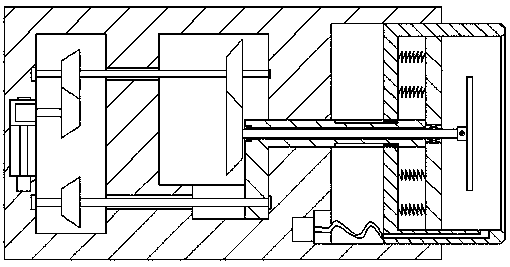

[0021] Such as Figure 1-Figure 5 As shown, an exhaust gas treatment machine of the present invention includes a hydraulic jacking device 5 and an absorption and purification structure 6 arranged on the top of the hydraulic jacking device 5 , and the inside of the right side of the absorption and purification structure 6 is provided with an accommodating groove 63 The accommodating groove 63 is slidably connected with an air collecting hood 64, the inside of the air collecting hood 64 is provided with an air collecting chamber 641, and the inside of the absorbing and purifying structure 6 on the left side of the accommodating groove 63 is provided with a transformation chamber 62, A first isolation plate 66 is provided between the transformation chamber 62 and the accommodation tank 63, and a drive chamber 61 is provided inside the absorption and purification structure 6 on the left side of the transformation chamber 62, and the drive chamber 61 and the A second isolation plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com