Adjusting Structure of Injection Rod for Die Casting Machine

A technology of adjusting structure and injection rod, applied in the field of die-casting machines, can solve problems such as troublesome installation and disassembly, achieve the effect of convenient installation and disassembly, and avoid fixed installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

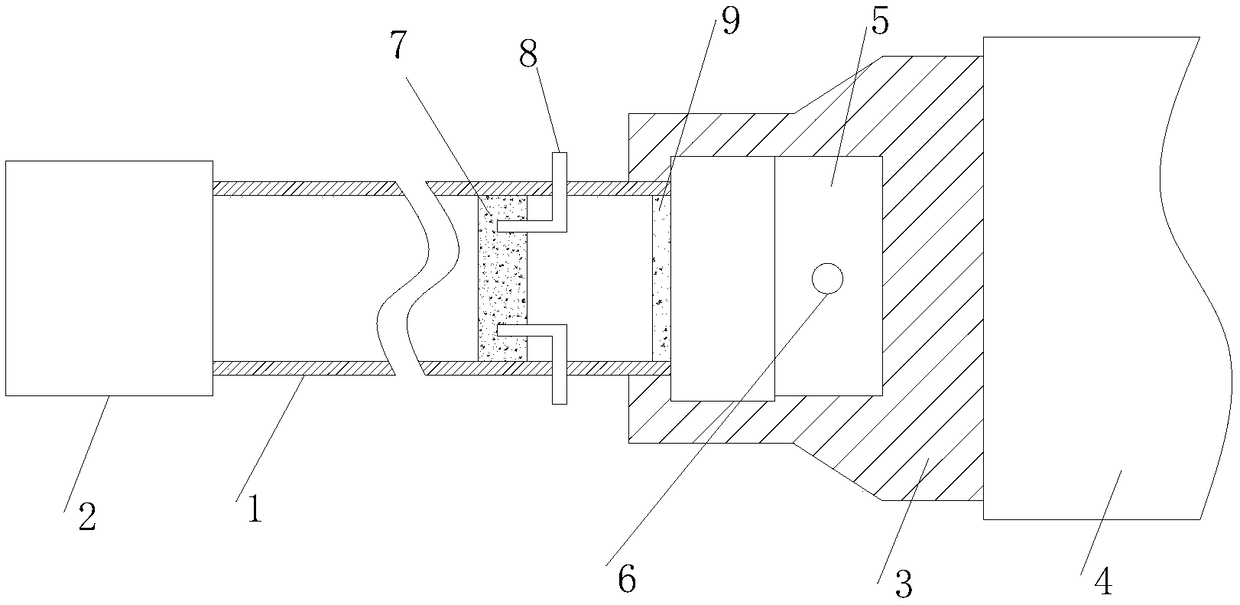

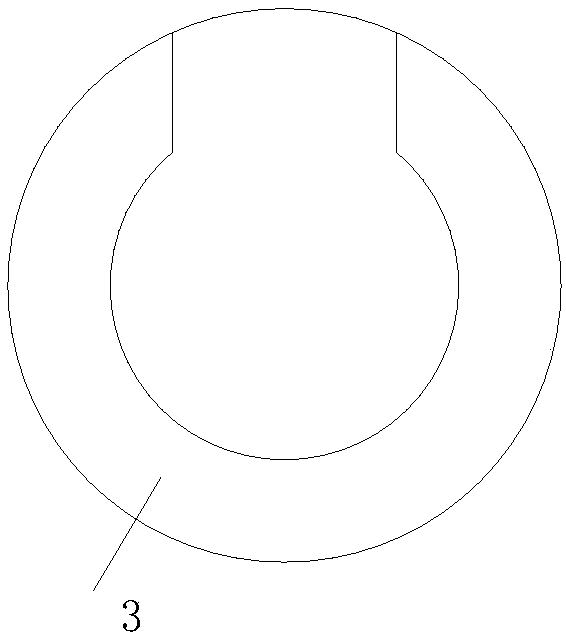

[0023] as attached figure 1 , 2 As shown, a plunger adjustment structure for a die-casting machine includes a plunger cylinder and a plunger rod 1 arranged at the front end of the plunger piston rod 4 of the plunger cylinder. A support block 3 with an opening is connected to the front end of the piston rod, and one end of the injection rod 1 is supported to the support block 3 and the other end is supported to the injection head 2 . The end of the support block 3 that is not connected to the injection piston rod has an opening, the diameter of the opening is smaller than the diameter of the abdomen, and the rear section of the injection rod has a diameter-changing shape, so that the part with a larger diameter of the injection rod sinks into the abdomen of the opening At this point, a snap-in effect is formed.

[0024] In addition, the length of the part with a larger diameter of the injection rod is less than the length of the abdomen of the opening, so that when the inject...

Embodiment 2

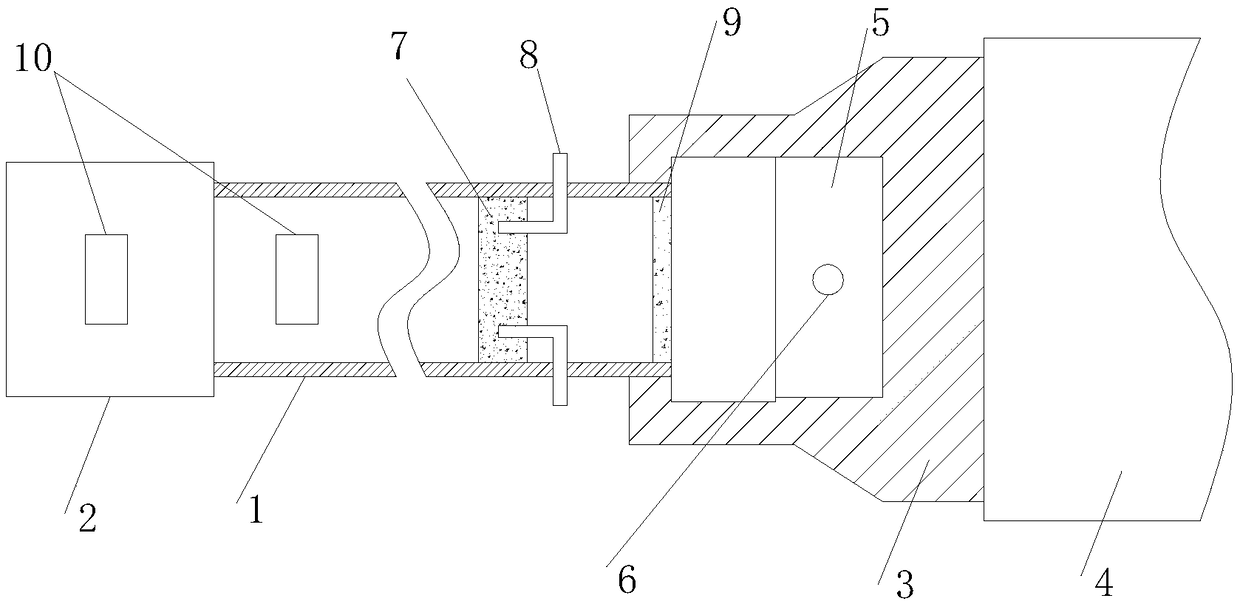

[0030] Such as image 3 As shown, as another embodiment of the present invention, a pair of grooves 10 are formed on the outer walls of the injection head 2 and the injection rod 1, and the grooves are cutouts made on the outer wall of the cylinder to facilitate the clamping of the cylinder by the wrench. The injection head and injection rod to facilitate their disassembly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com