Preparation method of fiber composite material and special equipment for preparation method

A fiber composite material and special equipment technology, applied in the field of fiber reinforced composite material preparation, can solve the problems of complex parts, inability to design freely, fiber composition and gradient that cannot be freely controlled, etc., to improve work efficiency and ensure uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to understand the technical solution of the present invention more clearly, the structure, principle and working process of the present invention will be further described below in conjunction with the accompanying drawings and implementation examples.

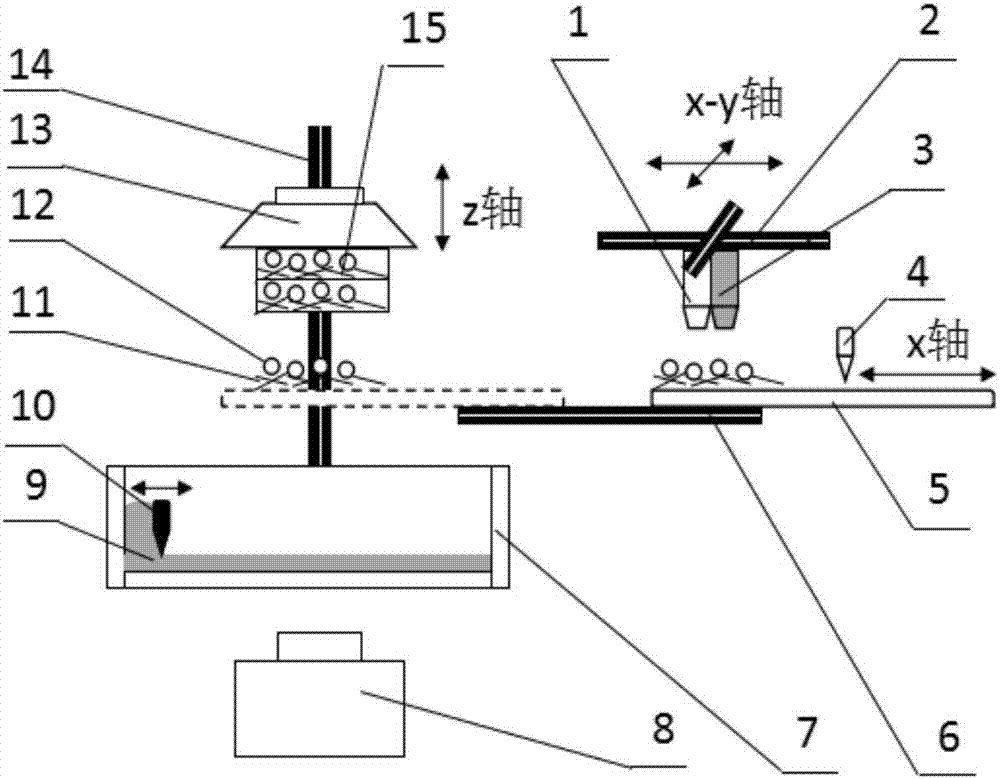

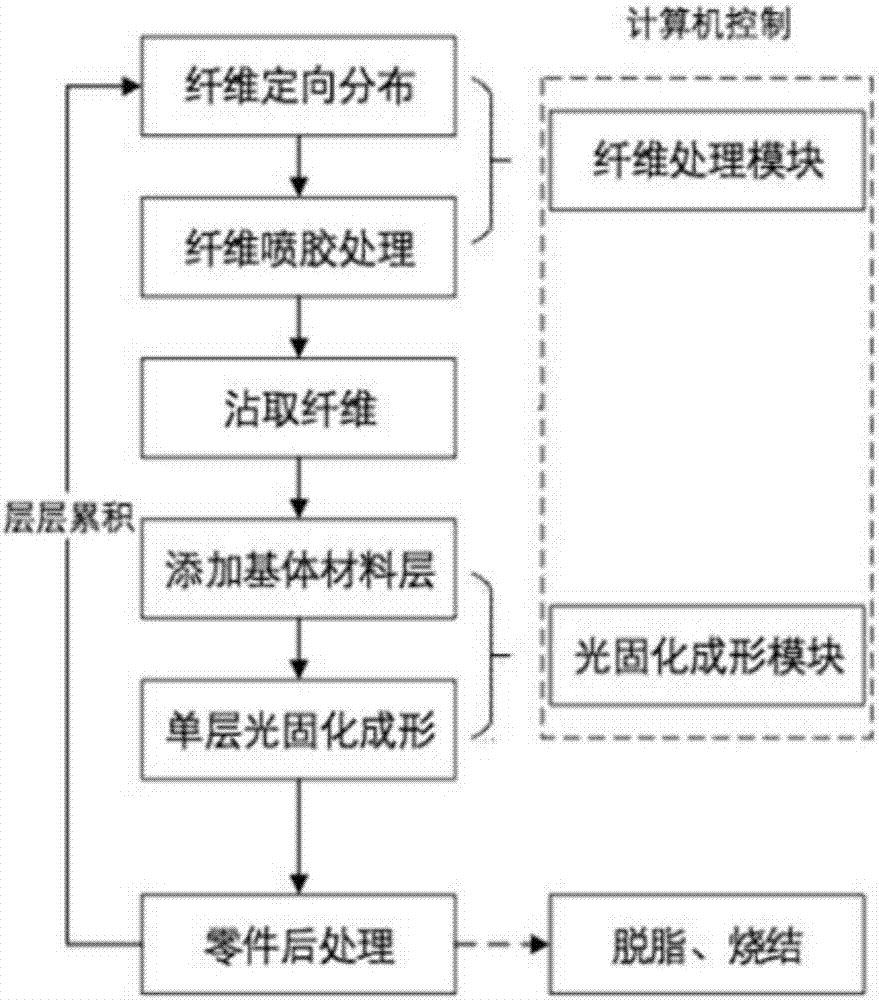

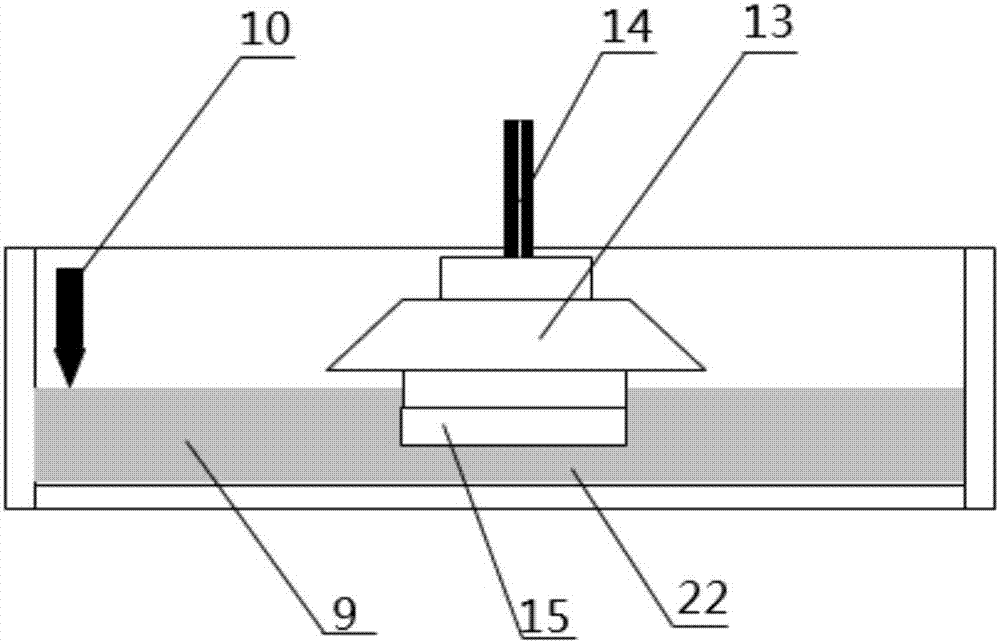

[0031] figure 1 It is a schematic diagram of the structure and principle of a special equipment for preparing fiber composite ceramic materials provided by the present invention. The equipment includes a frame, a fiber processing module, a light-curing forming module and a computer with control software.

[0032] The fiber processing module includes a fiber nozzle 1, a glue nozzle 3, a fiber bottom plate 5, a scraper 4, an X-Y plane movement mechanism 2 and an X-axis horizontal movement mechanism 6; the fiber nozzle 1 and the glue nozzle 3 are installed on the X-Y plane movement On the mechanism 2, the fiber base plate 5 is installed on the X-axis horizontal movement mechanism 6; the scraper 4 is located at one...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap