Road construction buffer fence

A road construction and fencing technology, which is applied in the field of road construction buffer fences, can solve the problems of not being able to effectively prevent out-of-control vehicles rushing to the construction site, poor buffering effect, etc., and achieve the effects of convenient replacement, safety protection, and reduced damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

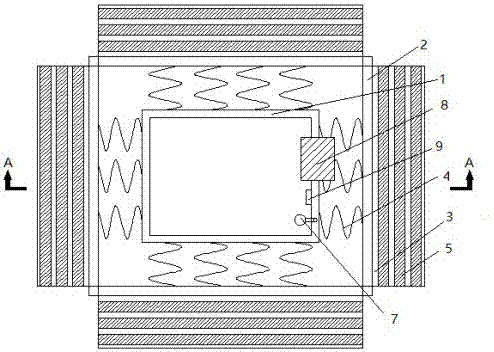

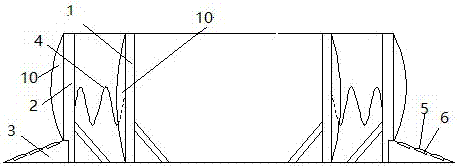

[0025] figure 1 , figure 2 Shows a road construction buffer fence, including an inner fence 1, an outer buffer fence 2 and a slope buffer part 3. The inner fence 1 is fixed on the ground at the periphery of the construction area, and the outer wall of the inner fence 1 is set perpendicular to the inner The spring 4 on the outer wall of the fence. The other end of the spring 4 is connected with an outer buffer plate 2 parallel to the outer wall of the inner fence. The bottom of each outer buffer plate is provided with a slope buffer part 3, and the slope of the slope buffer part 3 is inclined toward The exterior slopes downward.

[0026] When a car runs out of control and rushes to the road construction site, it will first contact the slope buffer 3. Since the slope buffer 3 is inclined, the out-of-control car will be slowed down due to upward work when it touches the slope buffer 3. At this time, if the out-of-control car continues to move forward, it will hit the outer buffer ...

specific Embodiment 2

[0028] In this embodiment, a deceleration belt 5 is added on the basis of specific embodiment 1. The slope of the ramp buffer 3 is provided with a convex deceleration belt 5, and there are more than two deceleration belts 5 on each slope.

[0029] The protruding speed bumps 5 are provided on the slope of the ramp buffer 3 to further slow down the out-of-control vehicle, and there are two or more speed bumps 5 on each slope to make the ramp buffer 3 have better deceleration effect.

specific Embodiment 3

[0031] This embodiment further describes the structure of the ramp buffer 3 on the basis of the specific embodiment 2. The slope of the ramp buffer 3 is also provided with a deceleration belt groove 6, and the bottom of the deceleration belt groove 6 is provided with a fixed In the hole position, the bottom of the deceleration belt 5 is provided with a convex part that matches the fixed hole position, and the deceleration belt 5 is placed in the deceleration belt groove 6.

[0032] A speed bump groove 6 is provided on the slope of the slope buffer 3, so that it is more convenient to replace the old speed bump 5, and secondly, the speed bump 5 can be adjusted according to the different conditions of the road construction site. The road construction site is located in the traffic flow When the road is larger and the speed is faster, replace it with a speed bump with a better deceleration effect. When the road construction site is on a relatively remote road with low traffic volume a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com