Approach bridge lifting mechanism of stepping type automatically moving trestle

A self-moving, step-by-step technology, used in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of limited expansion and contraction space of the cylinder structure, hard damage to the structure of the lifting cylinder, and inability to continue construction, so as to avoid the lifting height being affected. Limitation, avoid deformation and damage, easy disassembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and specific embodiment the invention is further introduced:

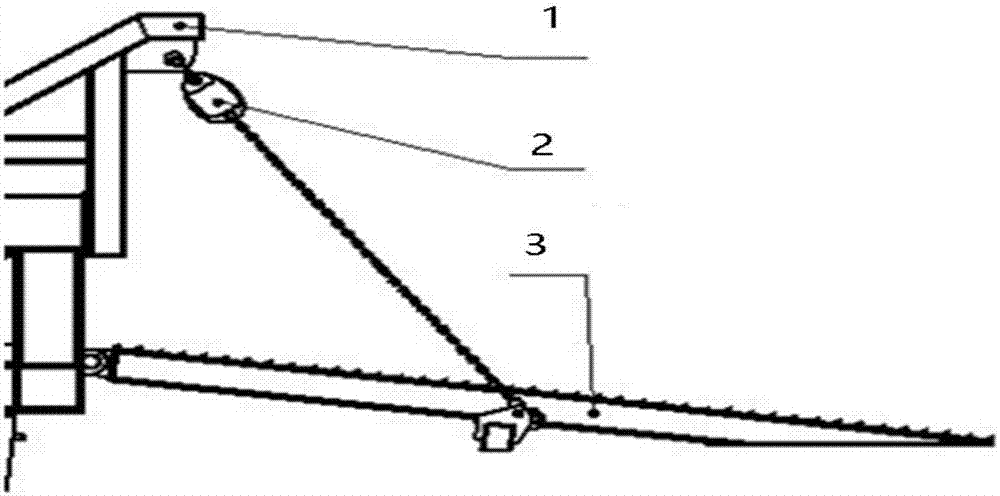

[0015] Such as figure 1 As shown, a step-by-step self-moving approach bridge hoisting mechanism includes an approach bridge 3, a main bridge body support hanger 1 and an electric hoist 2, and the electric hoist 2 has a hook connected to the same side of the approach bridge 3 with hoisting pull buckles; The electric hoist 2 hook is connected with the main bridge body with the side support hanger 1.

[0016] The number of further electric hoists 2 is 4, and two are respectively installed on the front approach bridge and the rear approach bridge. In the operating space, since each approach bridge has two left and right approach bridges, an electric hoist is installed on each of the left and right approach bridges, which is convenient for lifting; the wire rope electric hoist is small in size and easy to disassemble.

[0017] The further main bridge body supports ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com