Construction method for spliced cylindrical structure utilizing pipe jacking machine head for excavation

A construction method and assembled technology, which is applied in the direction of infrastructure engineering, construction, caisson, etc., can solve problems such as limited scope of application, large noise and vibration pollution, limited cylinder diameter and length, etc., to achieve wide application range, reduce Effect of noise and vibration, construction cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

[0029] A submerged shaft excavation method, the method comprises the steps of:

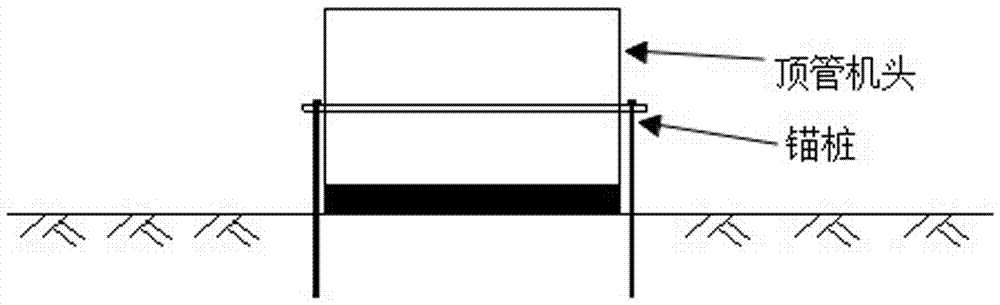

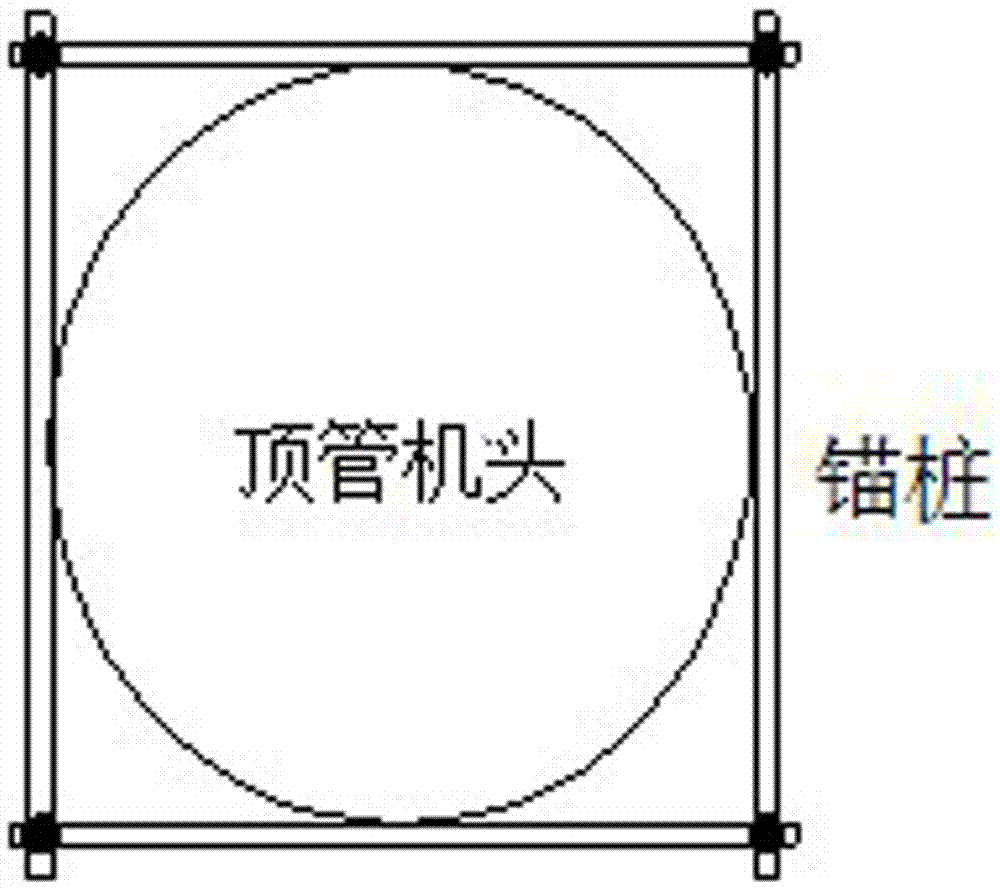

[0030] Step 1: Select the steel socket pipe and pipe jacking head according to the actual engineering situation and design requirements.

[0031] According to different hydrogeological conditions, the sealed or open electric pipe head can be used, and the diameter of the pipe jacking head can be flexibly adjusted (small (DN800~5000mm), medium (DN5000~15000mm), large (DN15000~20000mm) )). Using the pipe jacking head, each steel socket pipe can be directly guided into the design position, and the direction deviation can be corrected during the excavation process to ensure the excavation position and verticality.

[0032] The sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com