Reset Mechanism of Lock Cylinder Fixed Cross Mechanical Anti-theft Lock

A technology of mechanical anti-theft lock and reset mechanism, which is applied in building locks, building structures, construction, etc., can solve the problems of low processing precision, big troubles, increased contact pressure, etc., and achieve the effect of low cost and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

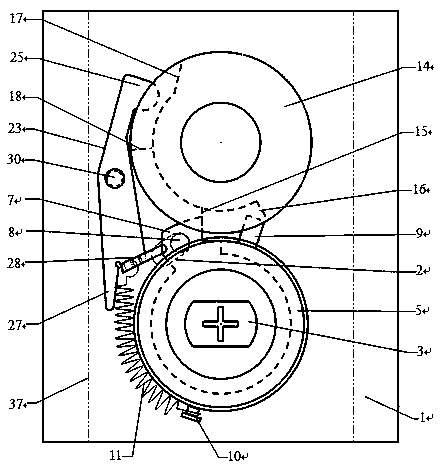

[0051] Implementation mode one: if figure 1 , 2 , 3, 4, 6, 7, 8, 9, 19, and 24, in the lock body of the lock cylinder fixed cross mechanical anti-theft lock, the cam mechanism and the lock cylinder group are installed between the anti-skid plate and the back plate 1 Among them, the cam mechanism includes a camshaft 13, a driven ring 14, an upper flange 15 and a lower flange 16 are arranged on the inner side of the inner side of the driven ring 14, and the driven ring 14 passes through the back plate 1. The part of the shaft hole includes a flat shaft part 21 and a round shaft part 22 at the end. The flat shaft part 21 is fixedly assembled with the main drive disc of the unlocking transmission mechanism and rotates synchronously. The round shaft part 22 is movably assembled with the swing rod. Core 3, inner rotating ring 4, outer rotating ring 5, dialing ring 6, locking post 9, return tension spring connecting post 10 and marble group, lock core 3 is fixed, dialing ring 6 and ...

Embodiment approach 2

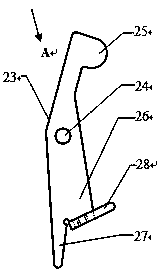

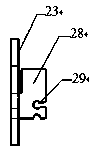

[0056] Implementation mode two: if Figure 5 , 11 , 12, 13, and 14 show that the reset lever 23 is cancelled, and the height of the outside of the reset push edge 18 is increased, that is, the push edge boss 20 is added, so that the push edge boss 20 can "reach enough" when the driven ring 14 reversely rotates “According to” locking column 9 and then promote its reset operation. The height of the flange boss 20 should be less than the gap between the driven ring and the outer rotating ring. Such as Figure 5 , 25 , Shown in 26, the upper end face of locking post 9 is slope shape, and purpose is to make the thrust of pushing edge boss can form the rotational moment to locking post 9 and outer rotating ring 5 reset operation.

[0057] exist Figure 5 Among them, the lock cylinder group and the cam mechanism are arranged horizontally, and the lock hole is located on the left side of the handle (that is, it corresponds to the right-hand door, and if it is on the right side, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com