Automatic bracket moving control method and bracket

A control method and frame moving technology, which is applied to the mine roof support, earth square drilling, mining equipment, etc., can solve the problems of long support time, easy roof fall in front of the frame, and coal wall slabs, so as to achieve fast moving speed and prevent The effect of roof caving and coal wall slabs in front of the frame, reducing the exposed area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0035] Preferred embodiment:

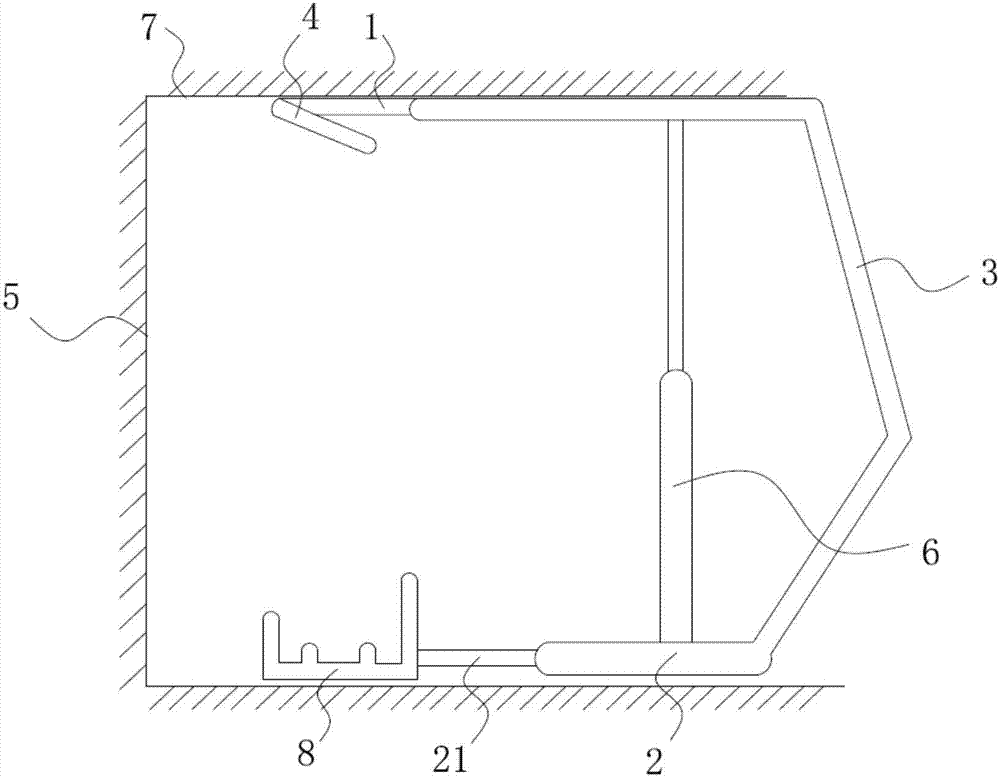

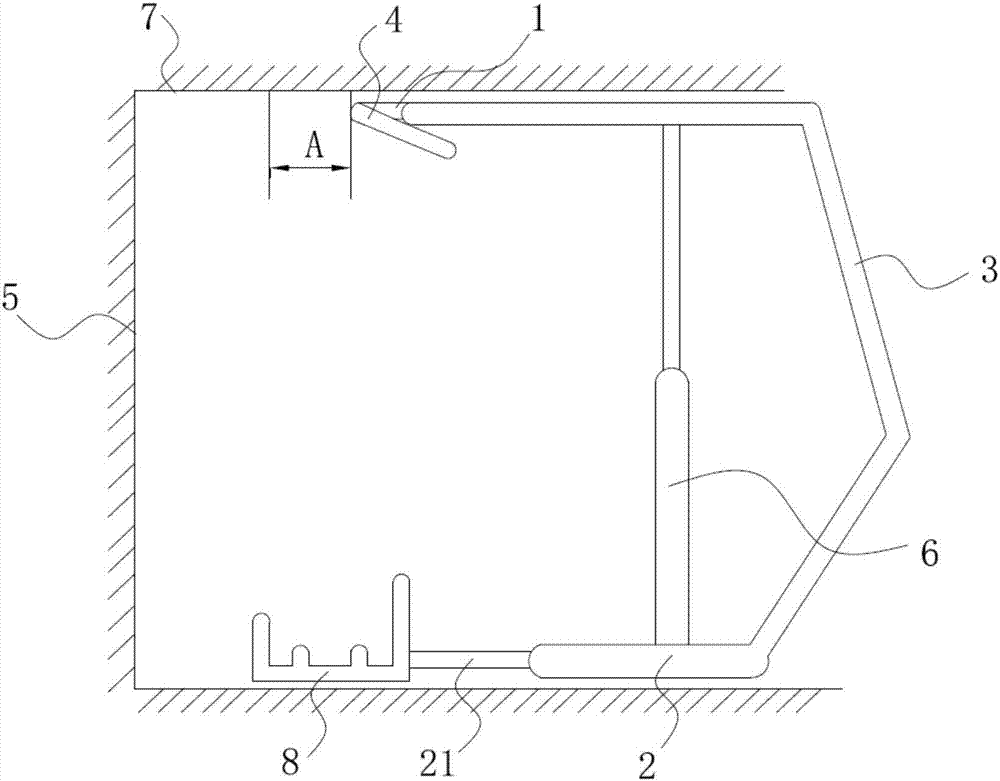

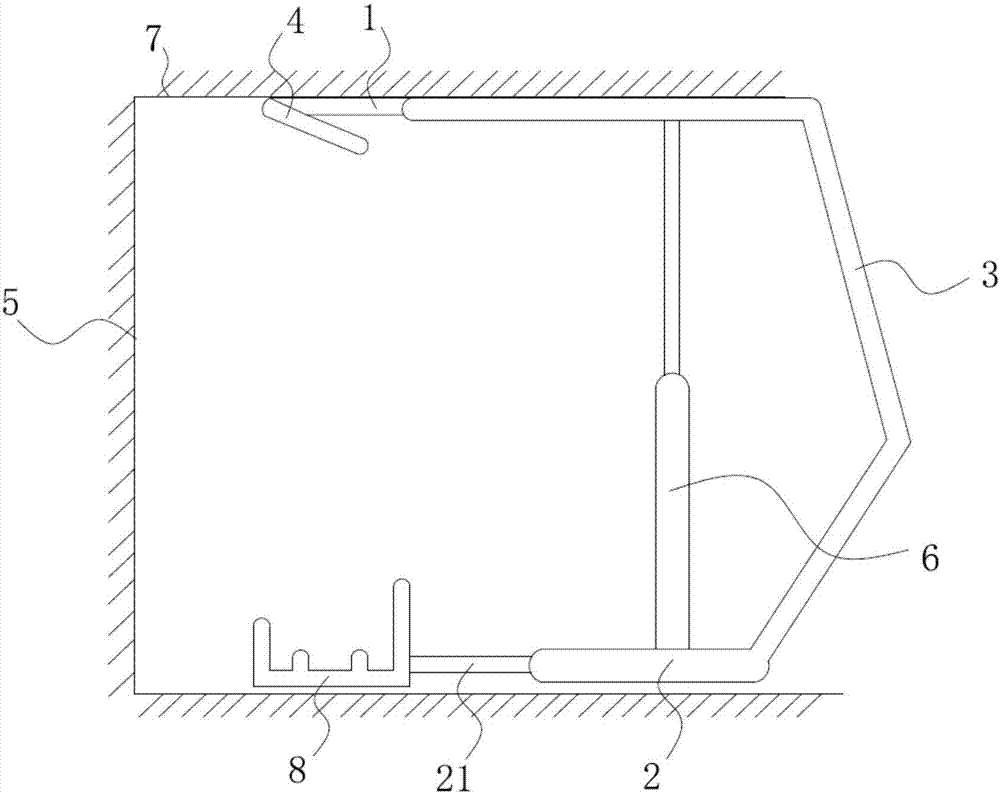

[0036] The preferred embodiment discloses a method for controlling automatic rack movement and a bracket for implementing the control method. Such as Figure 3 to Figure 7 As shown, the bracket includes a controller, a telescopic beam 1, a pushing cylinder 2, a side guard 4 and a column 6, and the cylinder hydraulic pipeline of the telescopic beam 1 is provided with a device for monitoring the real-time liquid supply flow and cooperating with the controller to control the liquid supply flow and realize the oil cylinder A flow sensor for action speed control; a flow sensor is arranged on the cylinder hydraulic pipeline of the push cylinder 2, and a stroke sensor for monitoring the real-time attitude of the push cylinder 2 is arranged in the push cylinder 2. When the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com