A method and device for real-time safety monitoring of mine ventilation system

A mine ventilation system and safety monitoring technology, applied in the direction of measuring devices, fluid velocity measurement, machine/structural component testing, etc., can solve problems such as judging and detecting the operation and stability of the ventilation system, complex correlation attributes of the mine ventilation system, etc. , to achieve the effect of safe and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

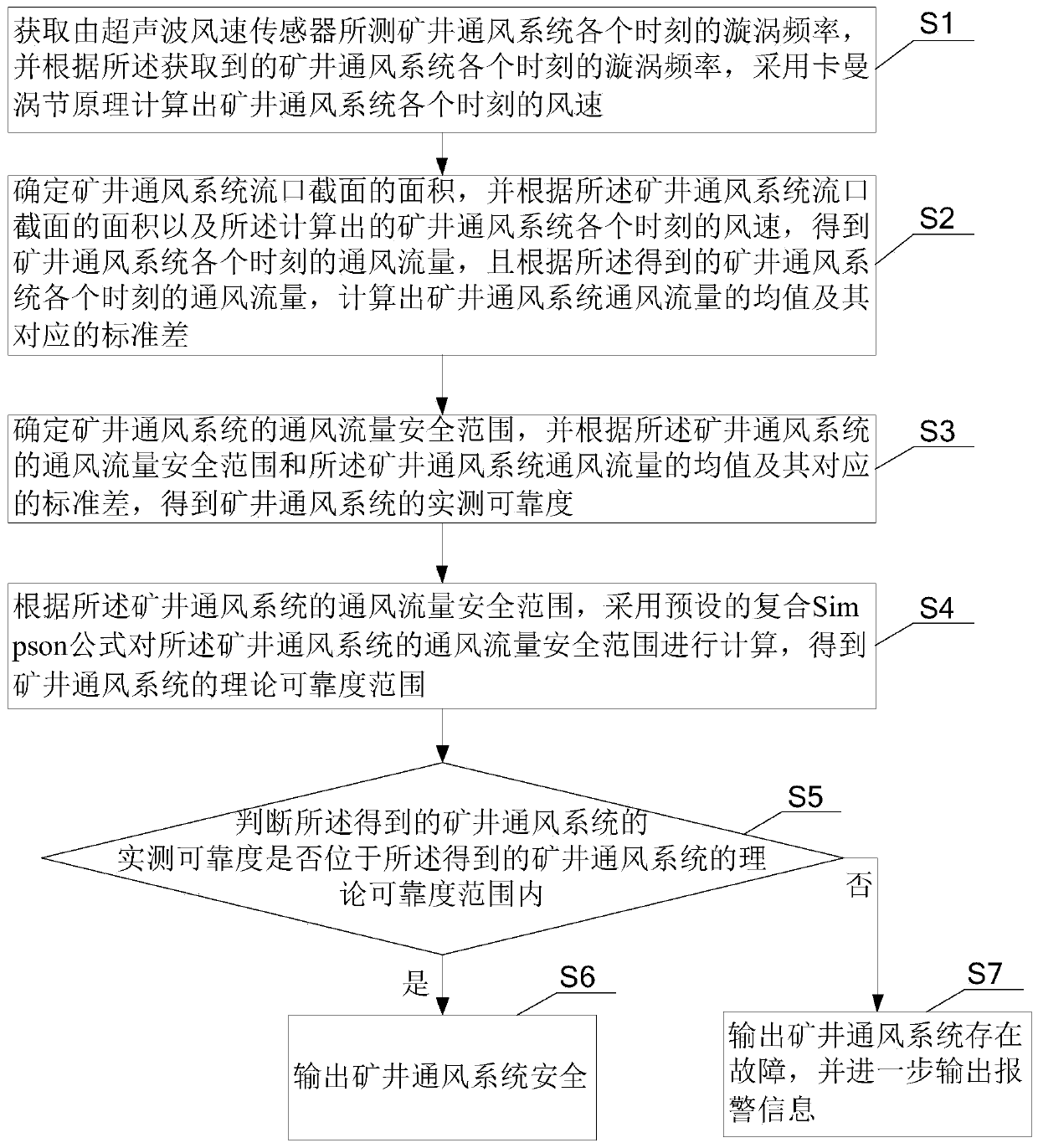

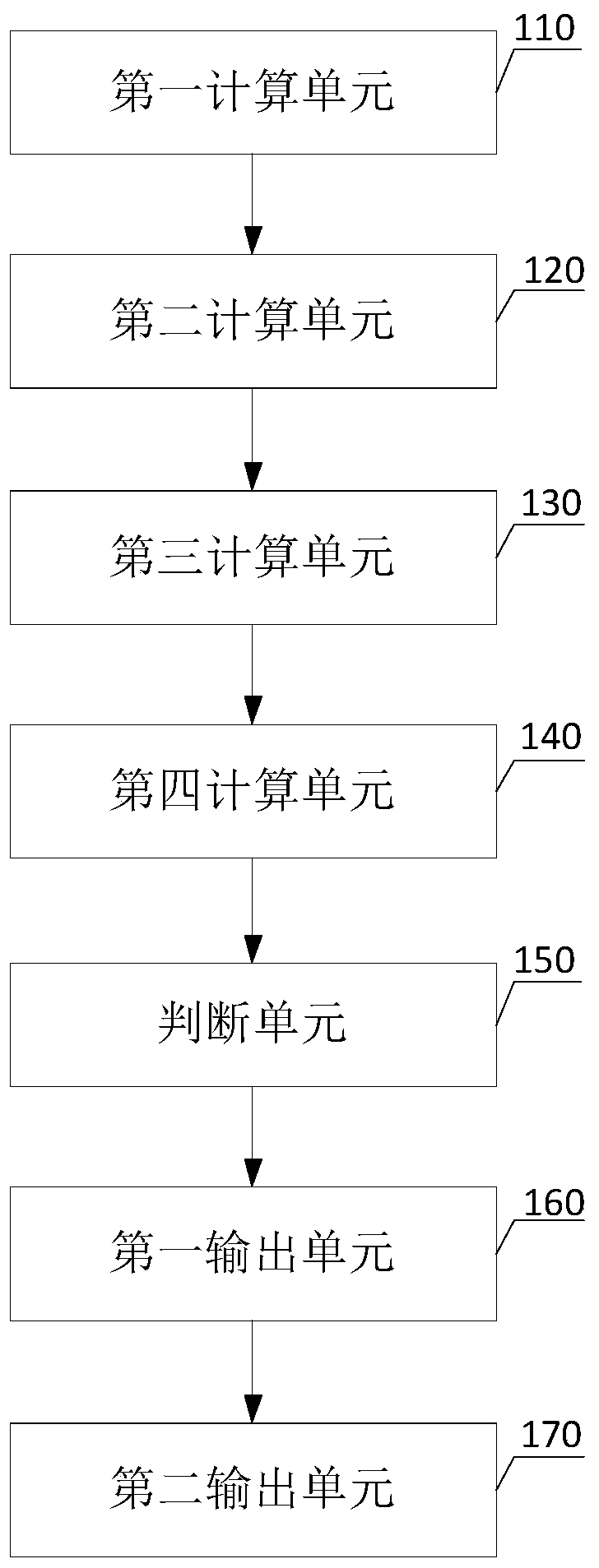

[0030] like figure 1 As shown, in an embodiment of the present invention, a method for real-time safety monitoring of a mine ventilation system is provided, and the method includes:

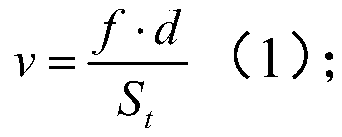

[0031] Step S1. Obtain the vortex frequency at each moment of the mine ventilation system measured by the ultrasonic wind speed sensor, and calculate the wind speed at each moment of the mine ventilation system according to the acquired vortex frequency at each moment of the mine ventilation system by using the Karman vortex principle ;

[0032] The specific process is to measure the vortex frequency at each moment of the mine ventilation system through the ultrasonic wind speed sensor, and use the formula (1) of the Karman vortex principle to calculate the wind speed at each moment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com