Method for calculating magnetic core loss of Boost converter

A technology of magnetic core loss and calculation method, applied in calculation, instrumentation, design optimization/simulation, etc., can solve the problems of multi-material parameters of the model, difficulties in practical application, etc., and achieve the effect of clear physical concept and simple calculation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

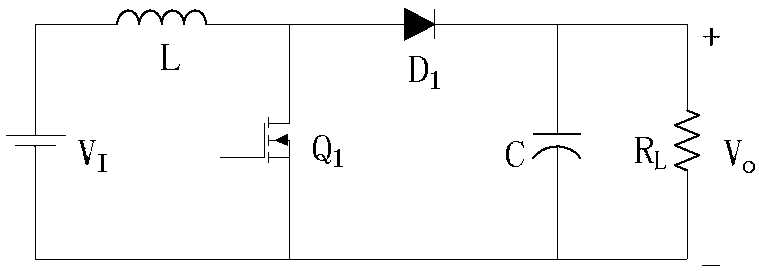

[0029] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

[0030] Such as figure 1 The Boost converter shown works in CCM mode, the inductance is positively excited during the conduction period of Q1, and the flux variation is:

[0031]

[0032] In the formula, V I Represents the input voltage, T represents the temperature, N represents the number of coil turns, A e Represents the cross-sectional area of the magnetic core, and D represents the duty cycle.

[0033] During the cut-off period of Q1, the inductance demagnetizes in reverse, and the amount of flux change is:

[0034]

[0035] In the formula, V O represents the output voltage.

[0036] The eddy current loss in the magnetic core per unit volume of the Boost converter can be expressed as:

[0037]

[0038] In the formula, R e is the core equivalent resistance.

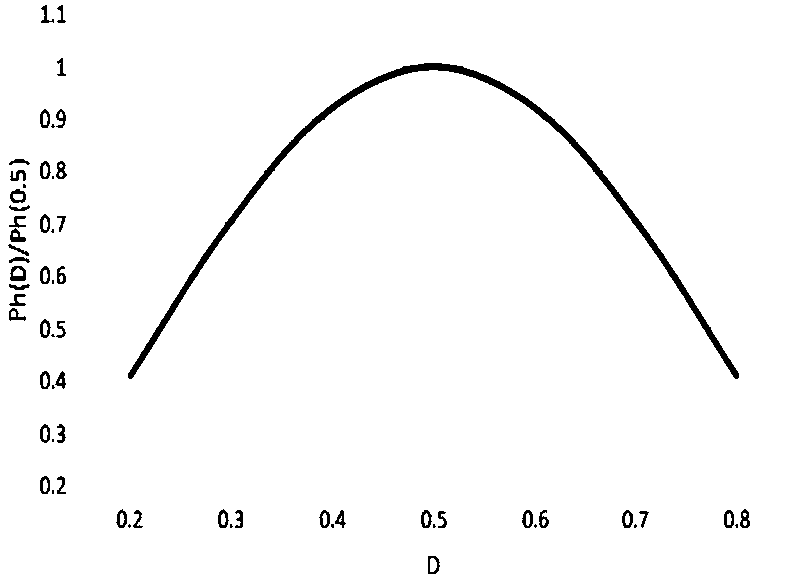

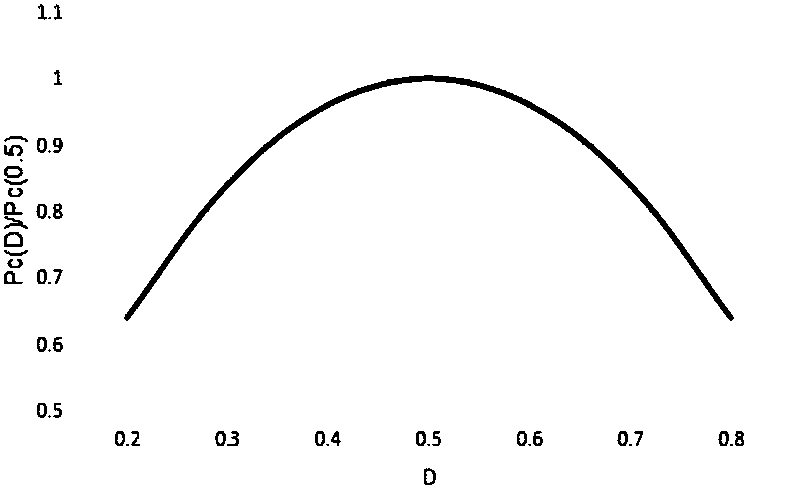

[0039] Eddy current loss under different duty cycle conditions Edd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com