Method for calculating magnetic core loss of Flyback converter

A technology of magnetic core loss and calculation method, applied in the direction of calculation, instrument, design optimization/simulation, etc., can solve problems such as practical application difficulties, model multi-material parameters, etc., to achieve the effect of clear physical concept and simple calculation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

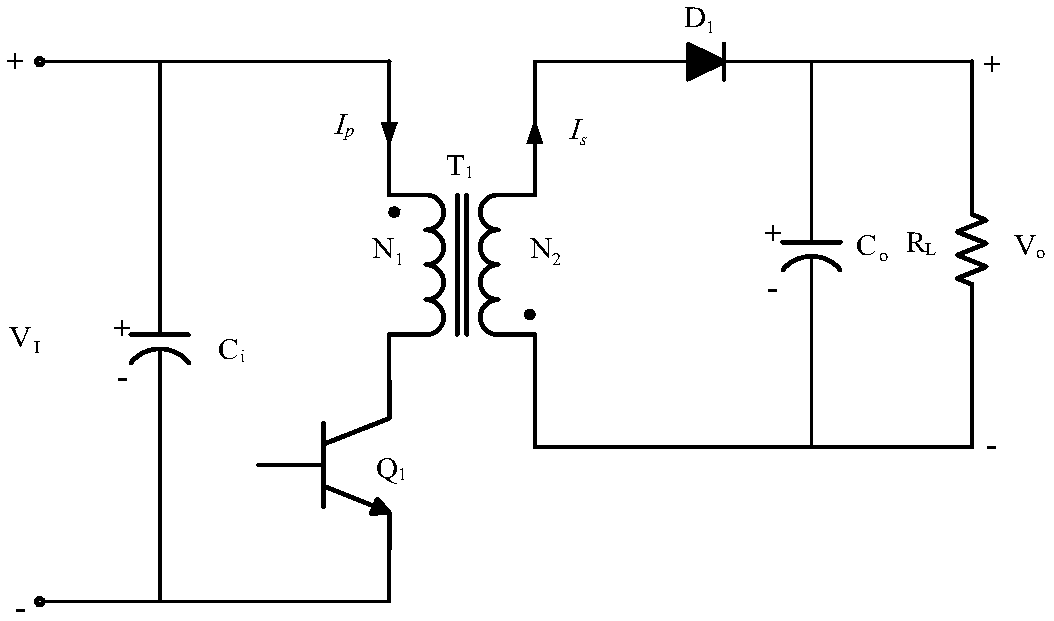

[0028] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0029] The Flyback converter magnetic core loss calculation method described in the present invention combines the physical mechanism of magnetic core loss and the operating characteristics of the Flyback converter circuit, and utilizes the advantage of the clear physical concept of the magnetic loss separation method to establish the Flyback converter power inductance in different occupations. The magnetic loss model under the condition of empty ratio.

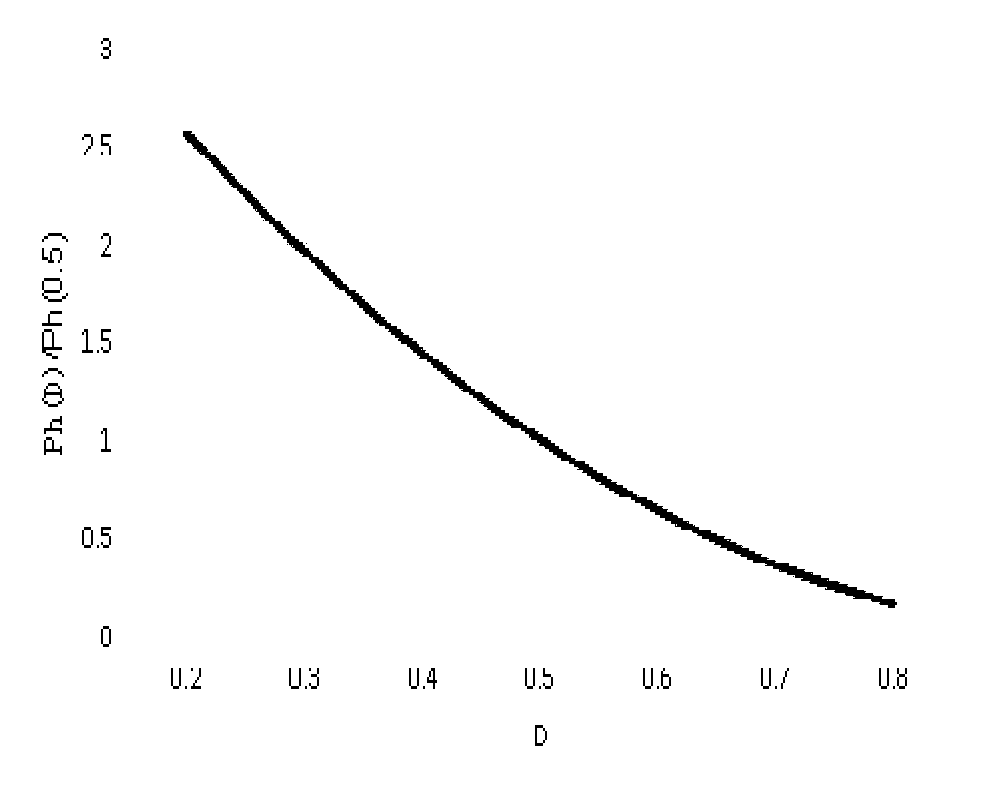

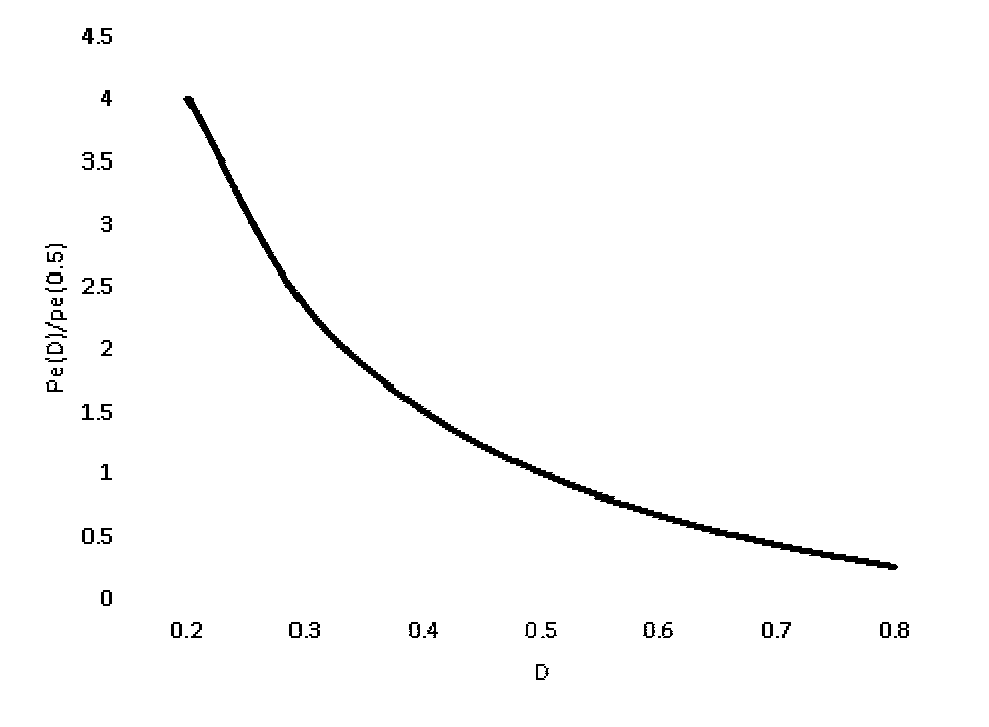

[0030] The method of the invention uses the loss data of the Flyback converter when the duty ratio D=0.5 under the given working conditions of DC bias, frequency and magnetic flux density variation to predict the magnetic core loss at different duty ratios.

[0031] Specific steps are as follows:

[0032] (1) Determine the duty cycle range of the magnetic core according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com