Dynamic monitoring method for internal energy loss of water turbine

A technology of internal energy and hydraulic turbines, applied in the direction of machines/engines, hydroelectric power generation, mechanical equipment, etc., can solve problems such as difficulty in distinguishing or dividing the composition of hydraulic turbine energy conversion losses, large errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0128] The real-time monitoring method for the internal loss of the water turbine proposed by the invention has a simple algorithm, and its core is the formulation of coefficients in the water turbine model. The following steps are included in the specific implementation.

[0129] Step 1: Determine the efficiency curve used to calculate the coefficients and calculate the characteristic parameters

[0130] 1) Calculation using the comprehensive characteristic curve of the model:

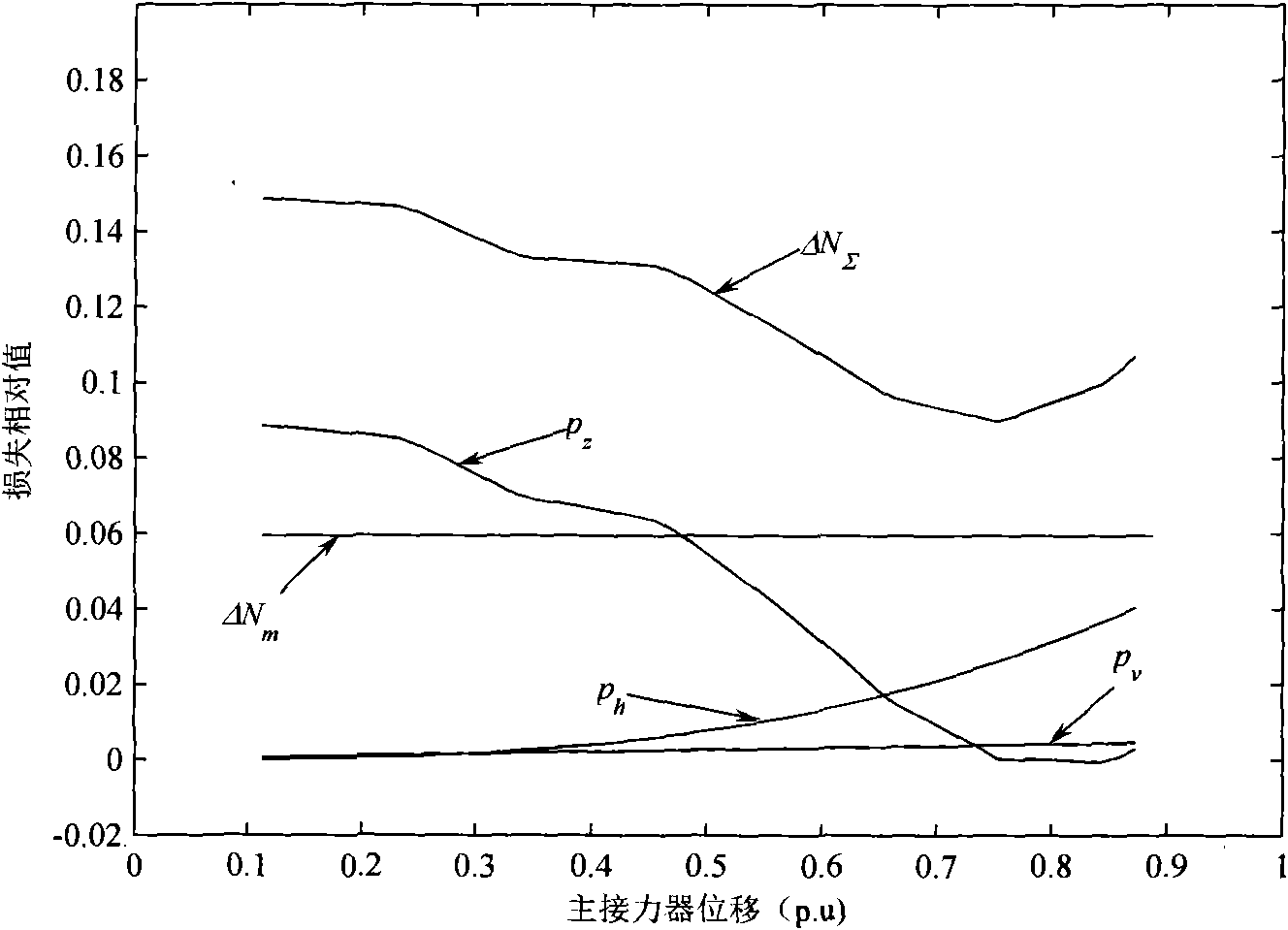

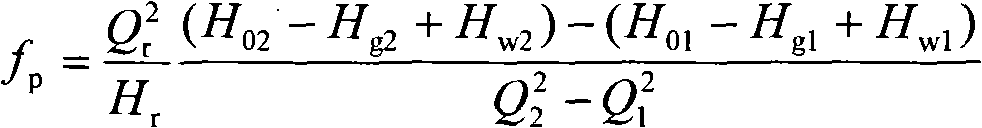

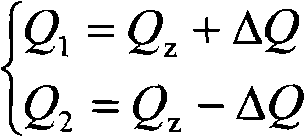

[0131] According to the unit parameters, select the rated water head H r For the corresponding unit speed, read the data from the comprehensive characteristic curve of the model, draw the efficiency curve under the rated water head, and determine the highest efficiency point. Find the flow Q at the point of maximum efficiency z , Output N z . The hydraulic loss coefficient f of the water diversion system p Estimate based on actual piping layout.

[0132] 2) Calculated using the measured efficie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com