Design method for high-efficiency metal dielectric reflection grating

A technology of dielectric reflection and design method, applied in the field of reflection grating, can solve problems such as design methods that have not yet been seen, and achieve the effect of clear physical concept

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

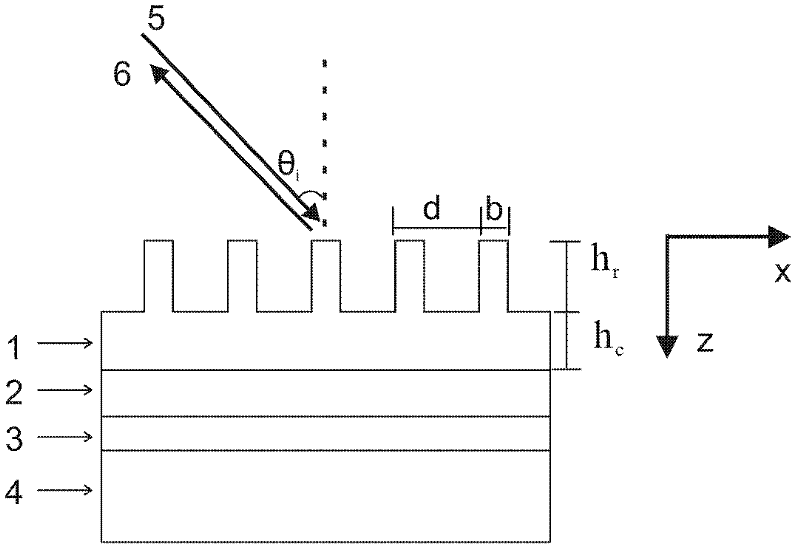

Embodiment 1

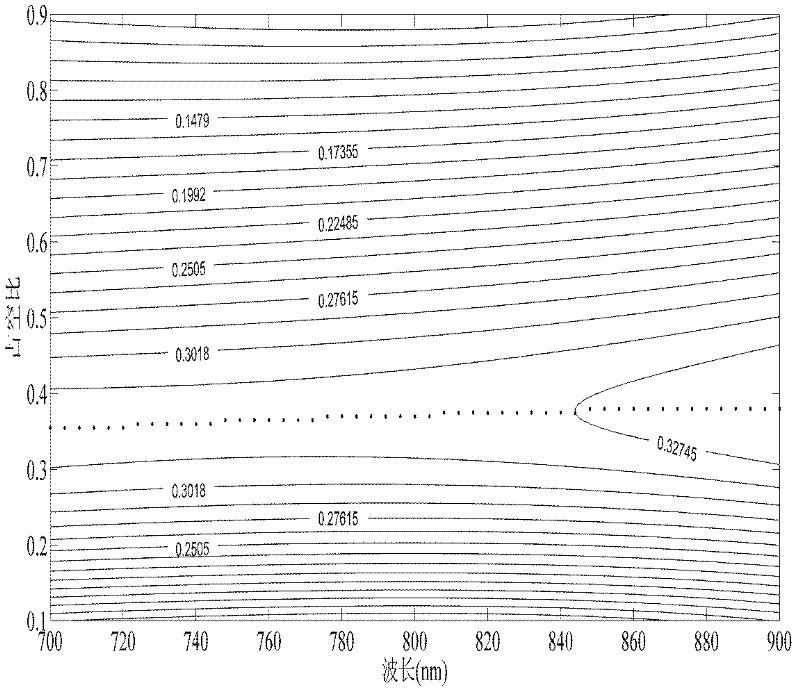

[0059] The design is suitable for a -1 level high-efficiency metal dielectric reflection grating with a wavelength of 800 nm. Its structure is that a 145 nm chromium film 3, a 150 nm gold film 2 and a fused silica film 1 are sequentially coated on a fused silica substrate 4, and the fused silica Layer 1 etches a grating of rectangular grooves. The duty cycle of the grating is 0.5, and the effective refractive index n of the 0-mode and 1-mode modes is calculated according to formula (1) 0eff and n 1eff , calculate the depth hr of the grating according to formula (5), and calculate the thickness h of the connection layer according to formula (8) c , considering the coating process, the value of l in the formula (5) and p in the formula (8) should not be too large, here l=0, p=1. The -1st order diffraction efficiency η of the corresponding grating is calculated using the strict coupled wave algorithm -1 .

[0060] Table 1 provides an embodiment of the present invention, where...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com