A method for fiber channel inspection in smart substations without power failure

A technology of intelligent substation and fiber channel, applied in the direction of transmission monitoring/testing/fault measurement system, etc., can solve problems such as inability to check and check, and inability to read message data by detection instruments.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

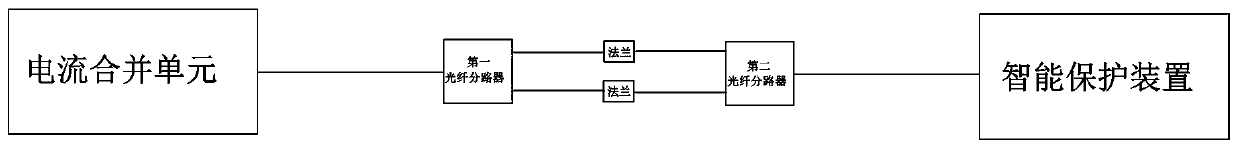

[0019] Such as figure 1 In the direct mining circuit of the present invention: an optical fiber is connected to one end of the first optical fiber splitter at the current combining unit of the intelligent substation, and the other end of the first optical fiber splitter splits out two optical fibers, and the two optical fibers They are respectively connected to one end of the second optical fiber splitter through flanges, and then an optical fiber is led out from the other end of the second optical fiber splitter to be connected to the intelligent protection device of the intelligent substation.

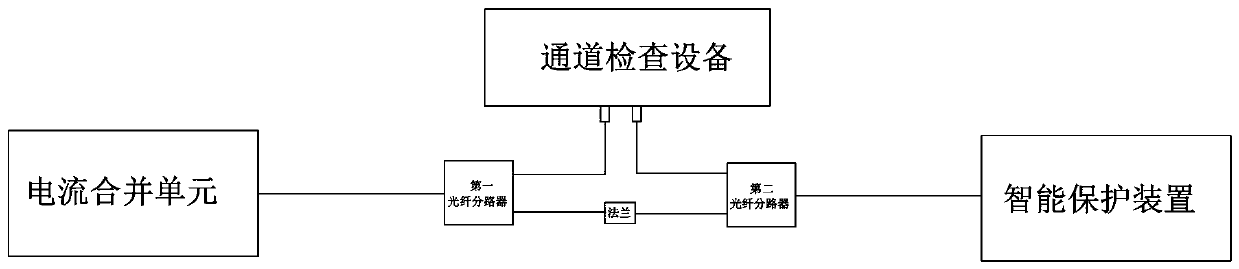

[0020] Such as figure 2 As shown, when the direct mining circuit performs fiber channel inspection, disconnect any optical fiber between the first optical fiber splitter and the second optical fiber splitter, and connect the two connectors of the disconnected optical fiber to the optical fiber together. Channel inspection device; thus, at this time, the normal optical fiber data at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com