Corner connector for rod-shaped profile elements

A corner connector and component technology, applied in furniture connection, connecting member, application and other directions, can solve the problems of complex frame or structure, unable to absorb corner pillars and side cheeks, unable to construct corner connectors, etc., to achieve simple disassembly, Quick and easy reassembly and disassembly, stable frame structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

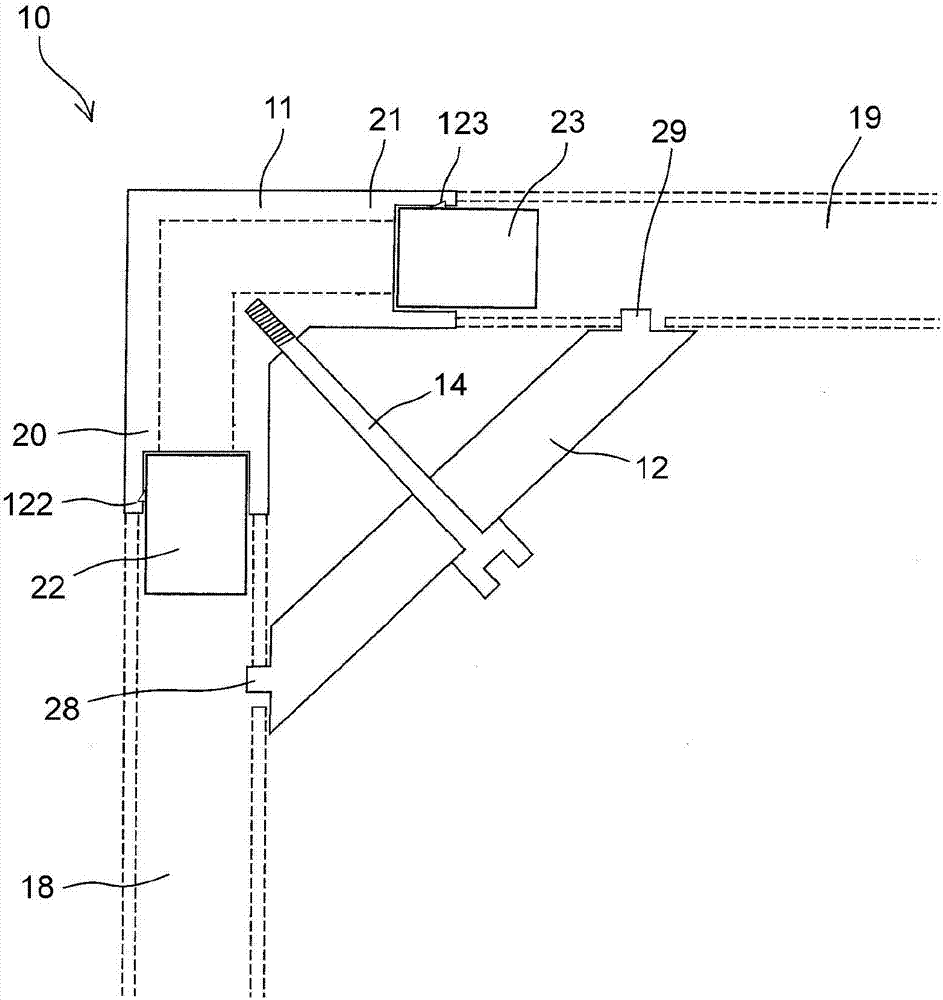

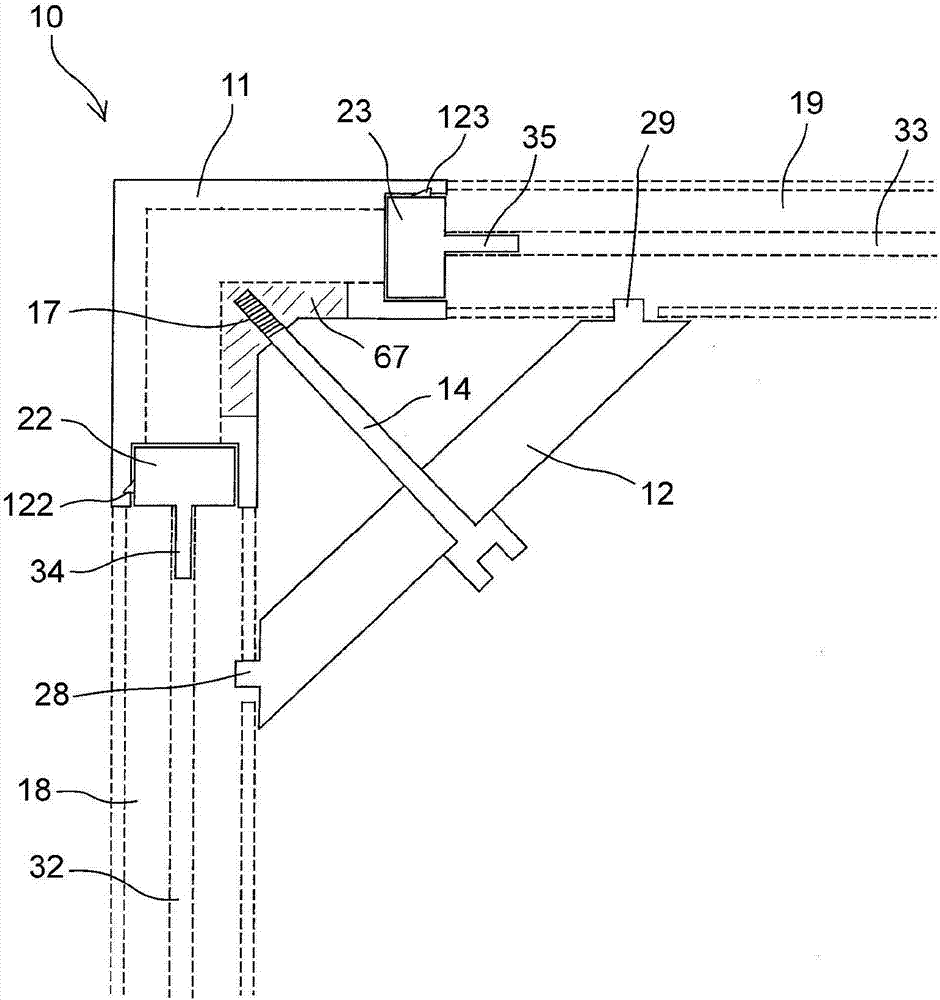

[0054] In the following description, components that perform the same or similar functions are denoted by the same reference numerals even though the specific configurations of the components vary in each embodiment.

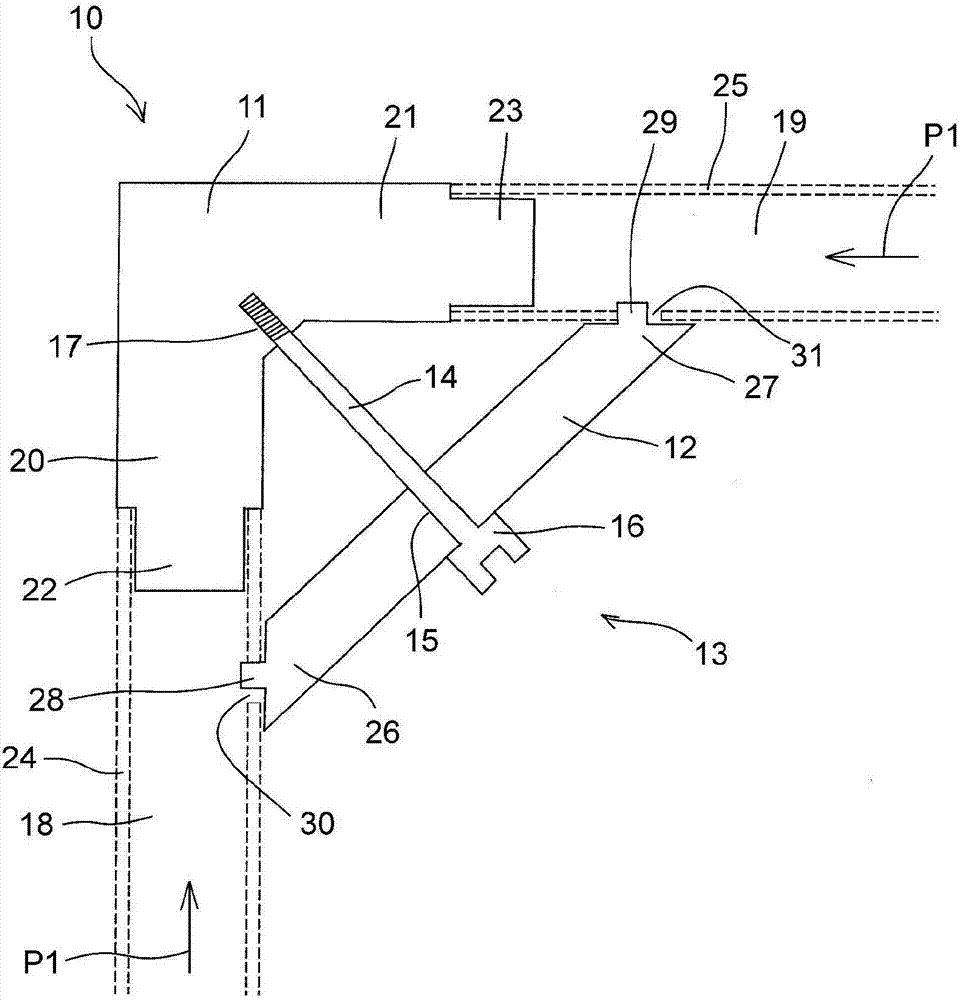

[0055] figure 1 A first exemplary embodiment of a corner connector 10 according to the invention for connecting rod-shaped profile elements is shown. The corner connector 10 comprises a connecting element 11 , a cross bar 12 and a tightening element 13 . In the example shown, the tightening element 13 comprises a hexagon socket head screw 14 inserted through a hole 15 formed in the crossbar 12 and whose screw head 16 rests on the crossbar 12 . The socket head cap screw 14 is screwed into a thread 17 formed in the connection element 11 . In the example shown, two rod-shaped profile elements 18, 19 (in figure 1 ) are connected to each other at an angle of 90° by means of connecting elements 11 . To this end, the connecting element 11 has two arms 20 , 21 which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com