Adaptive Intake Seal Fitting

An air intake joint, self-adaptive technology, applied in the direction of fuel air intake, pipe/pipe joint/pipe fitting, hose connection device, etc., can solve problems affecting noise control, affecting generator efficiency, leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Detailed embodiments of the present invention are disclosed herein, however, it is to be understood that the disclosed embodiments are merely illustrative of the invention, which may be embodied in various ways. Therefore, specific functional and structural details disclosed herein are not to be interpreted as limiting, but merely as a basis for the claims and as an instruction for those skilled in the art to variously employ the present invention in actually appropriately detailed structures. Explain the basics. It has actually been shown that the embodiments disclosed herein solve severe leakage problems compared to piping designs that do not include annular ribs, however, requiring the use of expensive constant tension compression plates.

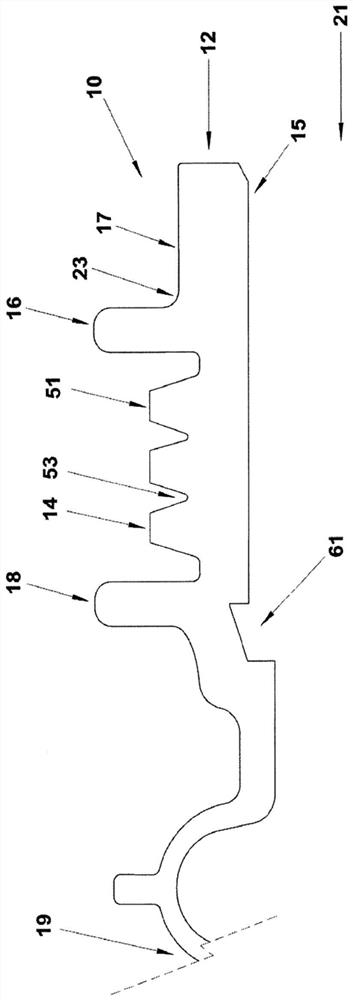

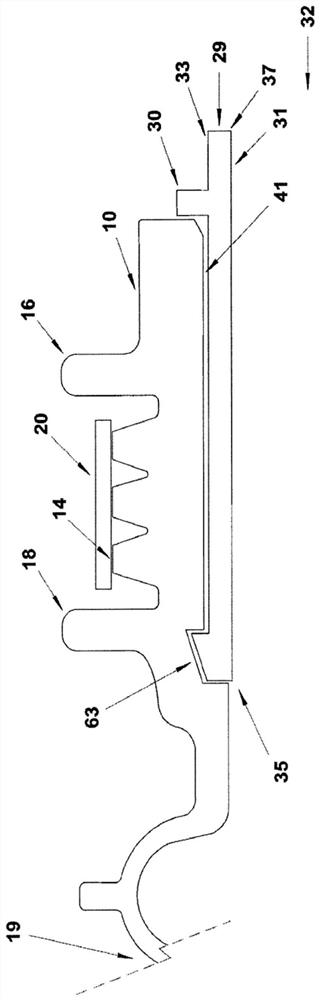

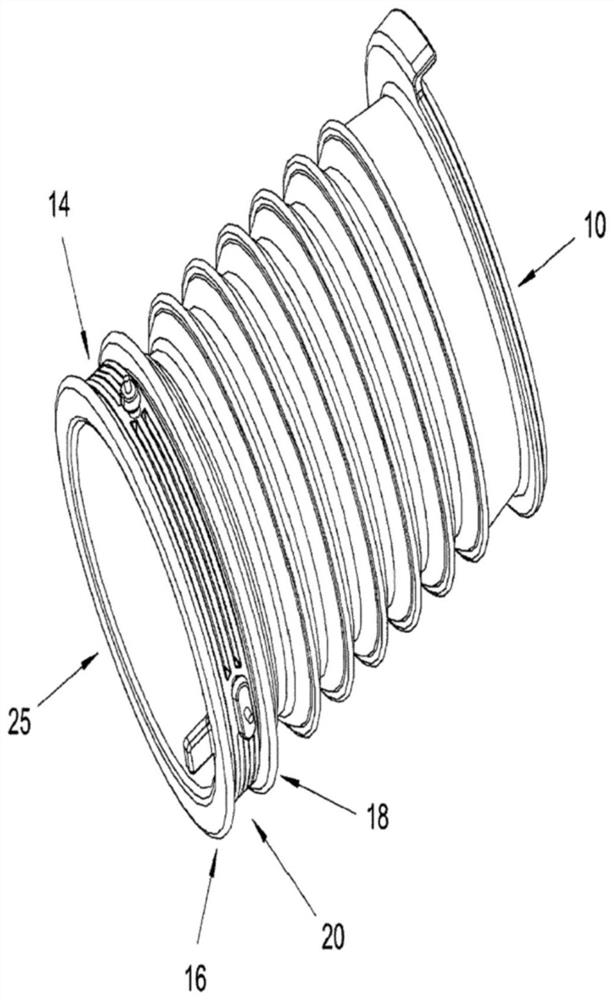

[0031] now refer to figure 1 , shows a conduit 10 having a construction of a special pipe material. For purposes of this discussion, the construction material may consist of rubber, TPE (thermoplastic elastomer), TPV (thermoplas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com