Coiling machine

A technology of coiling machine and machine body, applied in metal processing equipment, equipment for accumulating materials, manufacturing tools, etc., can solve the problems of synchronous stretching, increased production space occupation, waste of production resources, etc., to achieve the effect of convenient transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

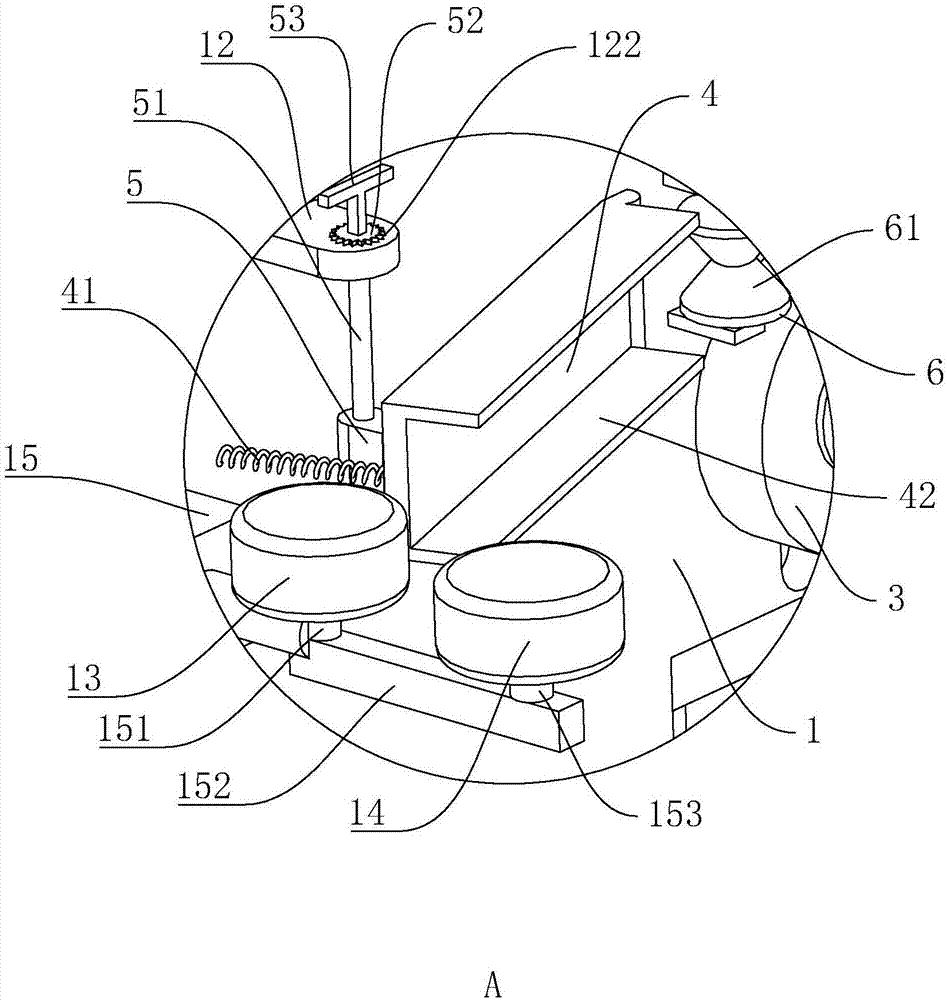

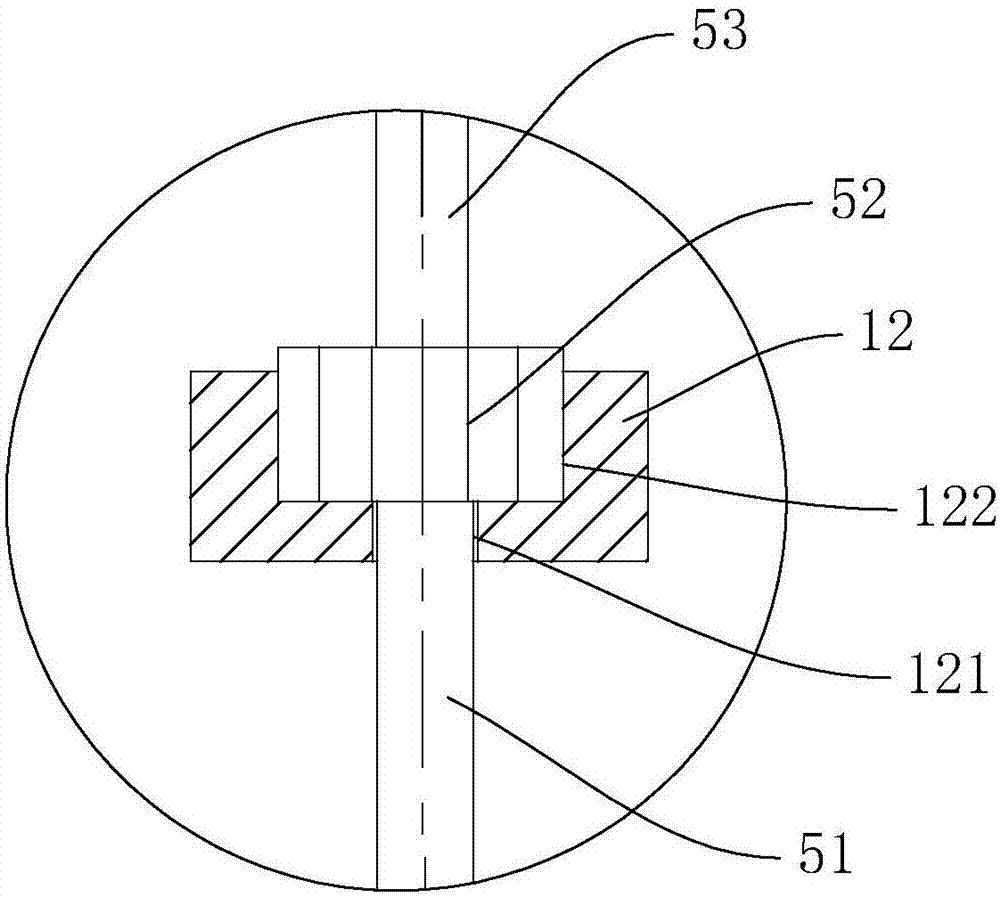

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

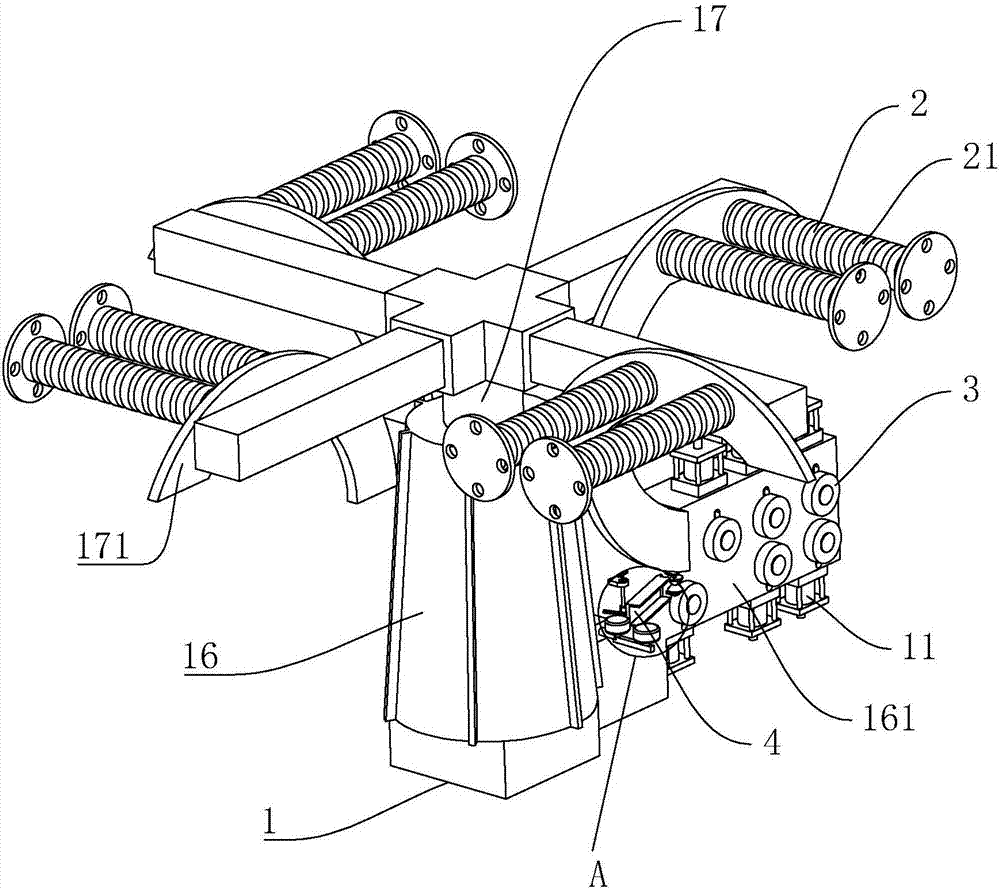

[0029] A coiling machine, refer to figure 1 , this kind of coiling machine includes a body 1, the body 1 includes a base 16 on the lower side, a rotating shaft 17 rotatably connected to the base 16, one end of the rotating shaft 17 penetrates into the inside of the base 16, and the inside of the base 16 is installed with a The reduction motor (not shown) that the rotating shaft 17 rotates; the peripheral side of the rotating shaft 17 away from the end of the base 16 is integrally provided with four mounting seats 171 that are half a C-shaped, and the four mounting seats 171 are on the rotating shaft 17. evenly spaced around the perimeter.

[0030]Mounting base 171 is symmetrically installed with two rewinding reels 2 for rewinding copper tubes, and the peripheral outer wall of rewinding reel 2 is provided with a plurality of annular grooves 21 for copper pip...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap