High pressure hydrogen refrigerating device for hydrogen fuel cell vehicle

A high-pressure hydrogen and fuel cell technology, used in refrigerators, refrigeration and liquefaction, compressors, etc., can solve problems such as affecting vehicle operation, consuming motors, and occupying large space for condensers and evaporators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

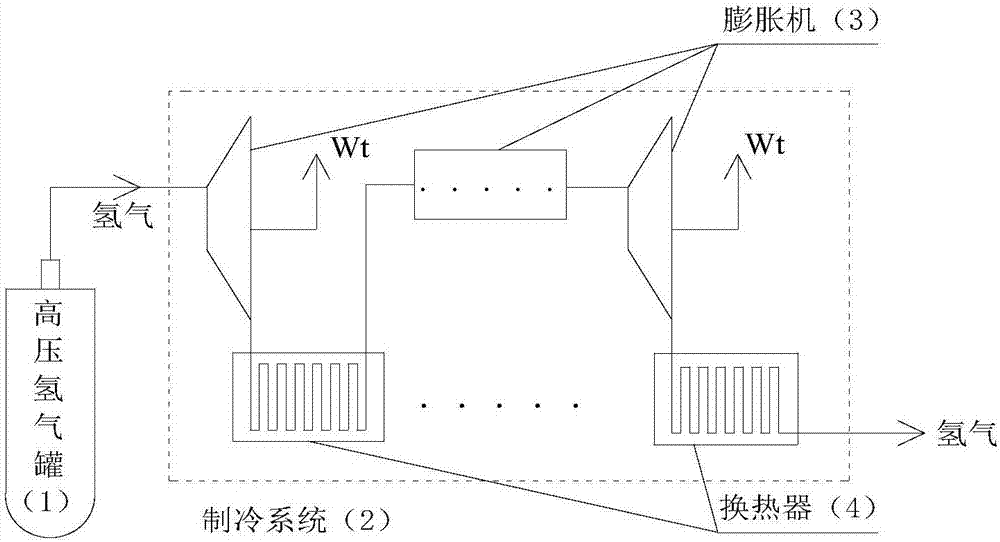

[0018] Such as Figure 4 As shown, a high-pressure hydrogen refrigeration device for a hydrogen fuel cell automobile includes: a high-pressure hydrogen tank (1), a refrigeration system (2), and the refrigeration system (2) includes an expander (3) and a heat exchanger (4). This case uses a one-stage expansion system. In the refrigeration mode: high-pressure hydrogen flows out of the high-pressure hydrogen tank (1), first passes through the piston expander (3) to reduce temperature and pressure, outputs work externally, and then flows into the air-cooled heat exchanger ( 4) Release cold to cool down the car interior.

Embodiment example 2

[0020] Such as Figure 5 As shown, a high-pressure hydrogen refrigeration device for a hydrogen fuel cell automobile includes: a high-pressure hydrogen tank (1), a refrigeration system (2), and the refrigeration system (2) includes a screw expander (3) and a water-cooled heat exchanger (4), the refrigerator in the car (7). This case uses a three-stage expansion system. High-pressure hydrogen flows out of the high-pressure hydrogen tank (1) and flows into the expansion system of each stage in sequence; in the expansion system of each stage, the hydrogen flows into the first-stage scroll expander (3) to reduce temperature and pressure, and Output work, and then flow into the first-stage water-cooled heat exchanger (4) to absorb heat; then flow into the second-stage scroll expander (3) to expand and depressurize, do work externally, and flow into the second-stage water-cooled heat exchanger (4) to absorb heat ; Finally, it flows into the three-stage scroll expander (3) to expand a...

Embodiment example 3

[0022] Such as Image 6 As shown, the hydrogen fuel cell vehicle gas supply system includes: high-pressure hydrogen tank (1), refrigeration system (2), expander (3), heat exchanger (4), condenser (8), hydrogen heater (9) ), hydrogen humidifier (10), water tank (11), water separator (12), air humidifier (13), fuel cell (14), water separator (15), air heater (16), compressor (17). Anode gas supply pipeline: Hydrogen flows out of the high-pressure hydrogen tank (1) and flows into the expansion system of each stage in turn. This case uses a two-stage expansion system; in the expansion system of each stage, the hydrogen flows into the first-stage radial expander (3). It flows into the first-stage air-cooled heat exchanger (4) to release the cold and cools the interior of the car; then flows into the second-stage radial expander (3) to expand and depressurize, perform external work, and then flow into the second Stage air-cooled heat exchanger (4) releases cold energy to cool the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com