Automatic packing machine for materials

An automatic packaging machine and material technology, applied in packaging, packaging protection, multiple packaging, etc., can solve the problems of difficult installation, troublesome work, unable to meet the needs of packaging various accessories at the same time, and achieve improved packaging efficiency and diversified packaging. The effect of improving the accuracy of sex and quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

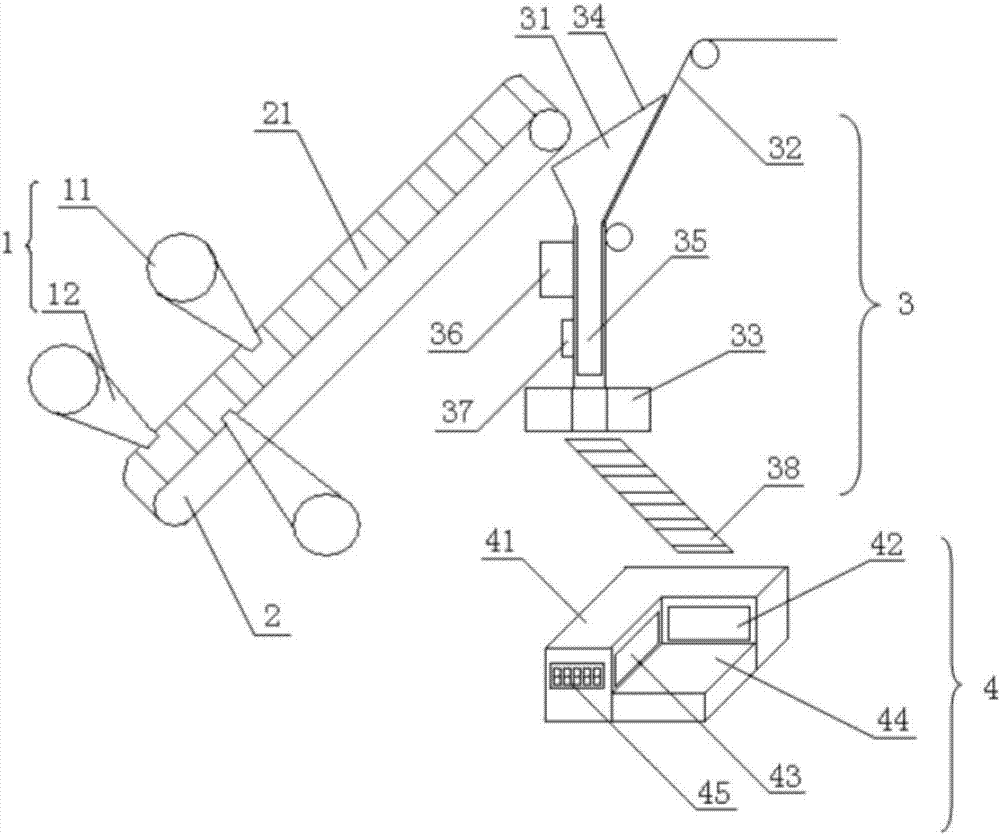

[0022] Depend on Figure 1-3 Combining the shown structures, it can be seen that this automatic packaging machine for materials includes a feeding mechanism 1, a feeding track 2, a packaging mechanism 3 and a weighing mechanism 4, and the materials from the feeding mechanism 1 are transported into the packaging mechanism through the feeding track 2 3. Carry out sealing and packaging, and the packaged materials enter the weighing mechanism 4 for weighing inspection.

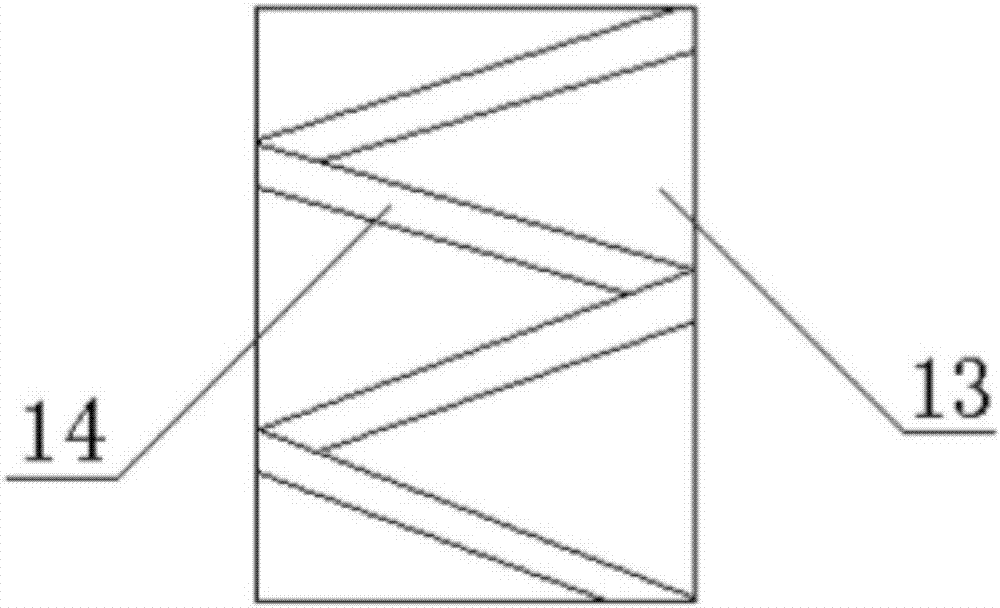

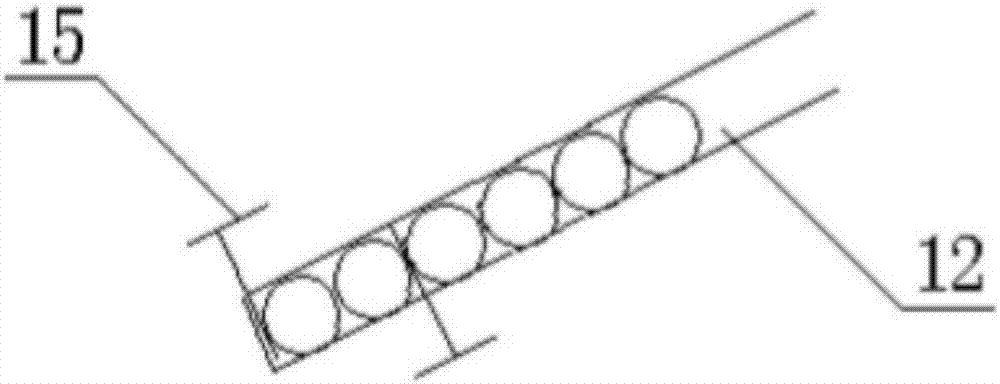

[0023] The feeding mechanism 1 includes several feeding trays 11 and discharge rails 12, the feeding tray 11 is a screw feeding device, including a screw conveying rail 14 arranged in a cylinder 13, and the spiral conveying rail 14 is driven to rotate by a stepping motor; the cylinder The top of 13 is also provided with the material outlet that is communicated with discharge track 12, and the material that is sent to the top through screw conveyor track 14 enters discharge track 12 through material outlet. Severa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com