A permeable water storage module and its manufacturing method

A technology of permeable bricks and water storage materials, which is applied to pavements, roads, buildings and other directions paved with prefabricated blocks, can solve the problems of changing the drawing environment, reducing the efficiency, and consuming large amounts of energy, so as to protect the water and soil environment and improve reliability. improve the overall effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

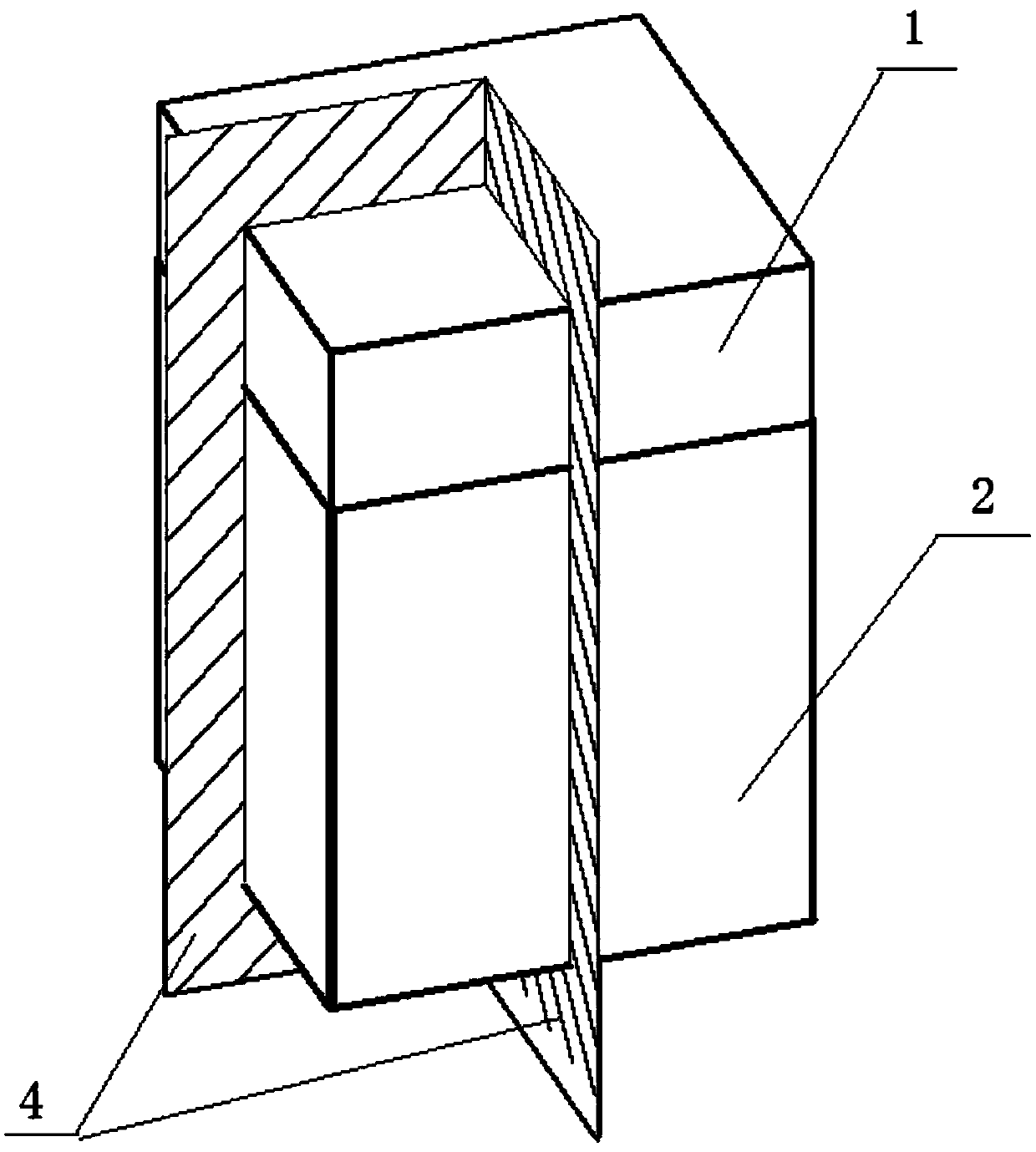

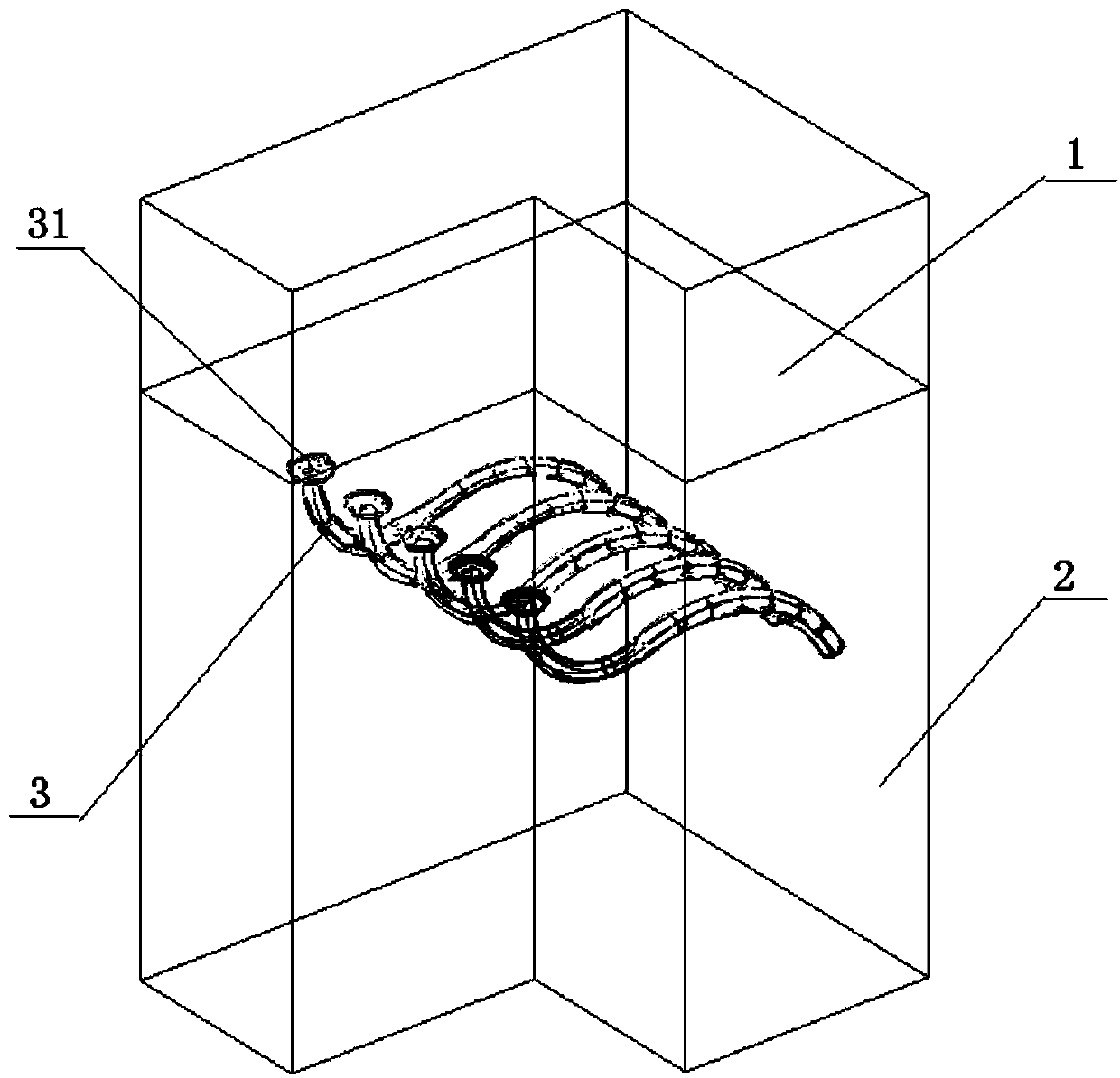

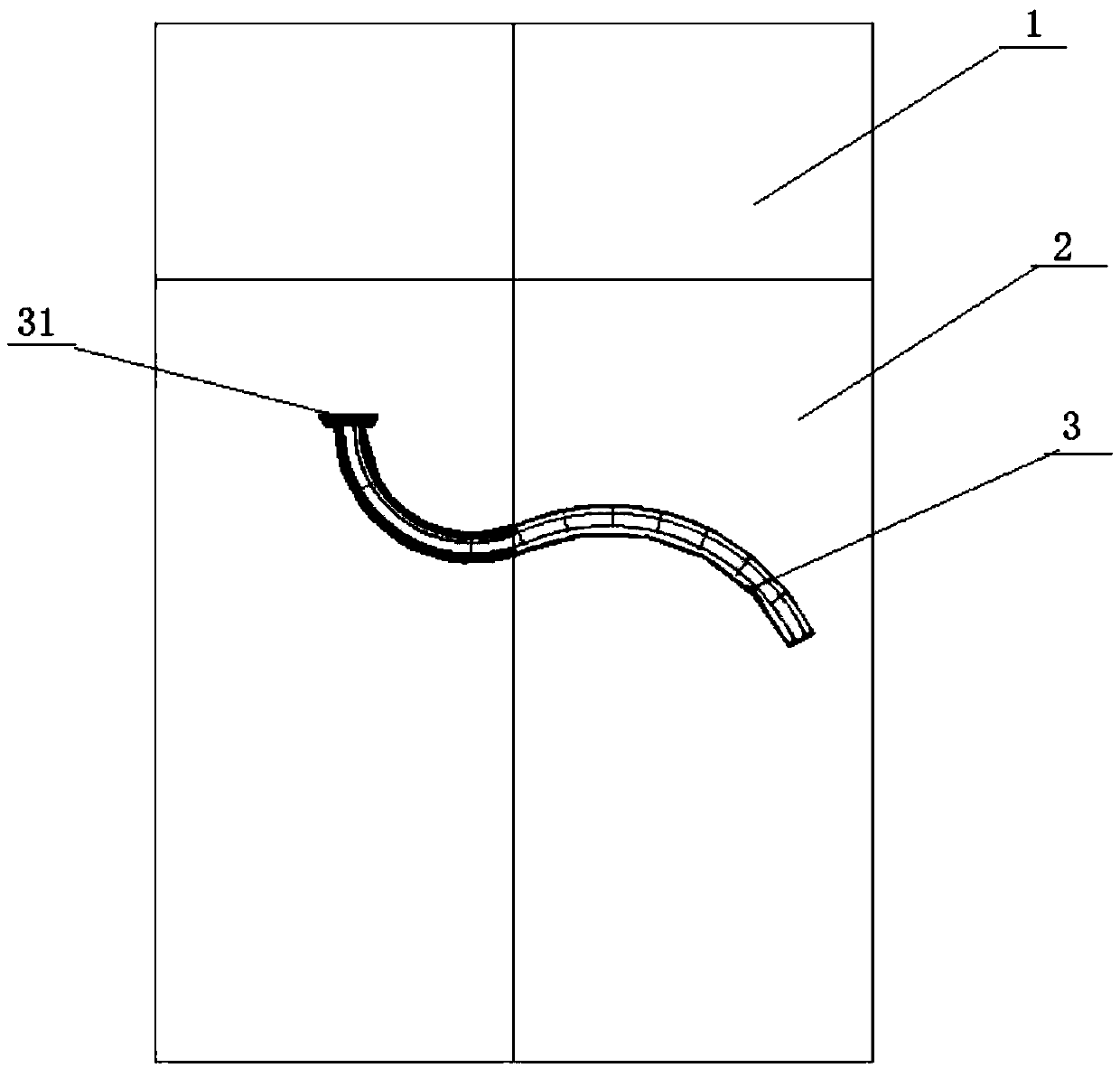

[0063] 1. A water storage and permeable module, comprising a composite water permeable brick layer 1 and a filling water storage material layer 2 located below the composite water permeable brick layer 1, and a siphon type drainage and storage device is arranged in the filling water storage material layer 2.

[0064] The composite permeable brick layer 1 on the upper layer of the module is composed of a layer of composite permeable bricks 11. The composite permeable bricks 11 are combined by cement and a high molecular polymer. The high molecular polymer can be epoxy resin. In this embodiment, the composite permeable brick is used. The bricks are 6cm high, 23cm long and 9cm wide. The bottom surface of a single composite permeable brick is provided with a plurality of sawtooth grooves 12 for embedding and filling the upper surface of the water storage material layer 2. The cross section of the sawtooth grooves 12 of the composite water permeable brick 11 can be square, such as ...

Embodiment 3

[0076] 1. A water storage and permeable module, comprising a composite water permeable brick layer 1 and a filling water storage material layer 2 located below the composite water permeable brick layer 1, and a siphon type drainage and storage device is arranged in the filling water storage material layer 2.

[0077] The composite permeable brick layer 1 on the upper layer of the module is composed of a layer of composite permeable bricks 11. The composite permeable bricks 11 are combined by cement and a high molecular polymer. The high molecular polymer can be epoxy resin. In this embodiment, the composite permeable brick is used. The bricks are 5cm in height, 16cm in length and 12cm in width. The bottom surface of a single composite permeable brick is provided with a plurality of sawtooth grooves 12 for embedding and filling the upper surface of the water storage material layer 2. The cross section of the sawtooth grooves 12 of the composite water permeable brick 11 can be sq...

Embodiment 4

[0089] This embodiment is basically the same as Embodiment 1, except that the height of the water storage module in this embodiment is 7m, and the distance between the inflection point 34 of the middle pipe axis of the siphon pipe 3 and the top of the water storage module is 5.5m.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com