Oilway structure

A technology of oil circuit and structure, applied in the direction of fluid transmission, belt/chain/gear, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

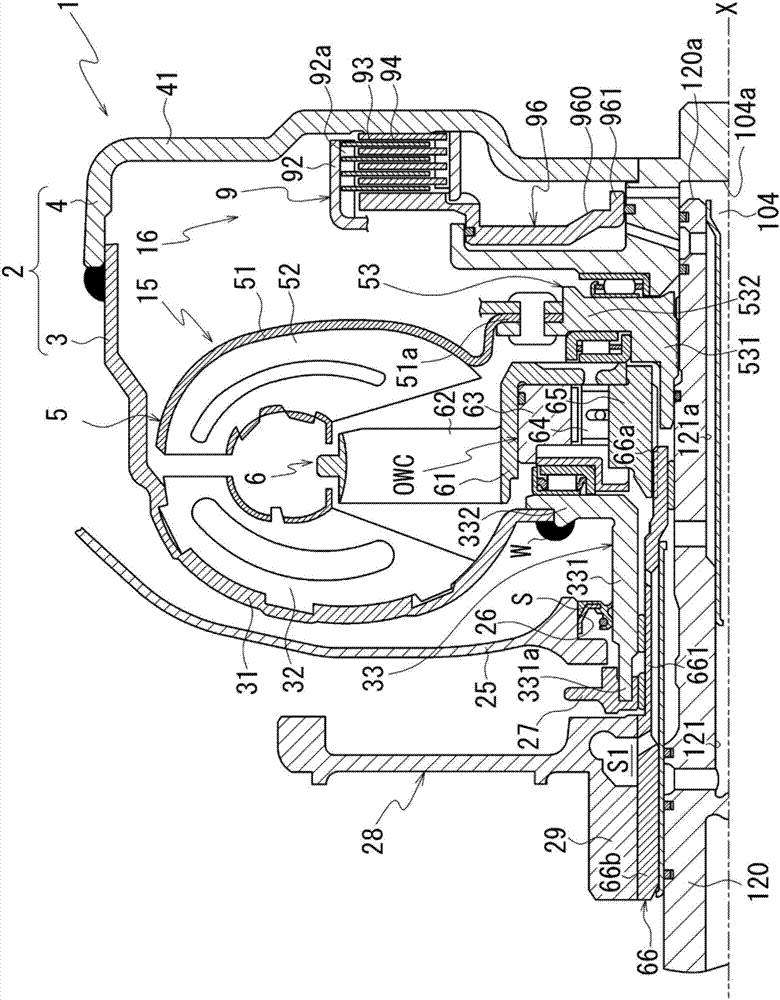

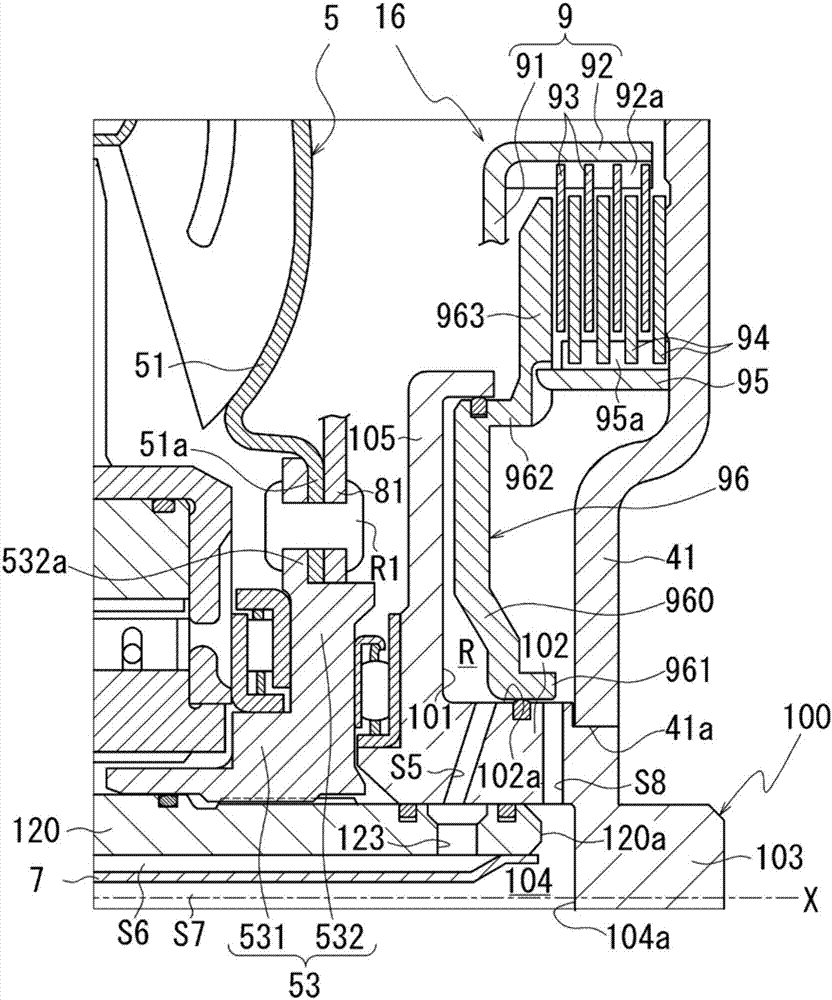

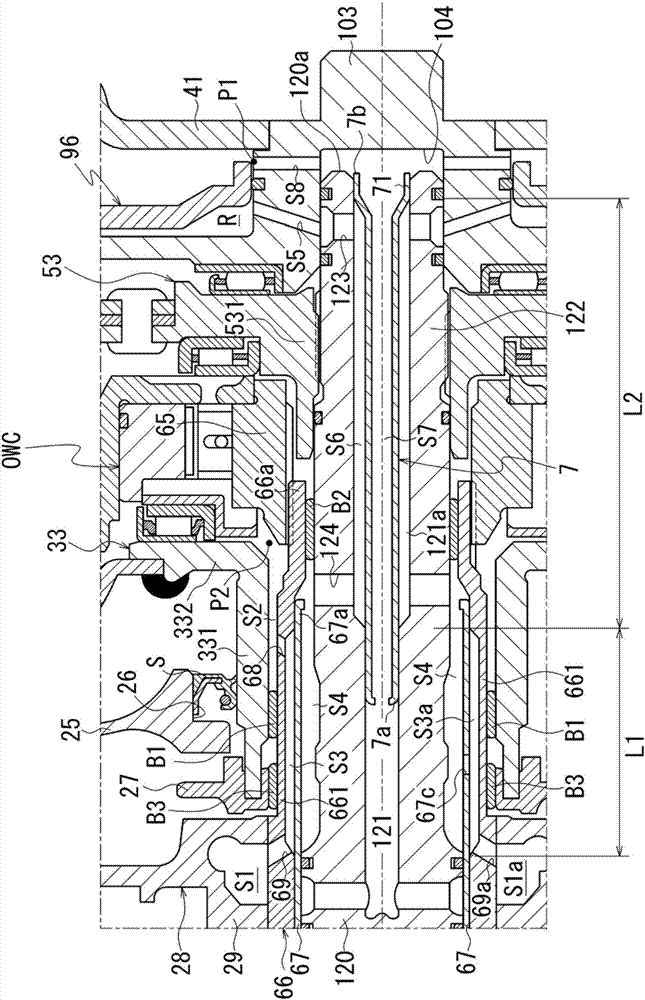

[0090] Hereinafter, an embodiment of the present invention will be described by taking a case where the oil passage structure of the present invention is applied to the oil passage structure of the torque converter 1 as an example. figure 1 It is a diagram explaining the oil passage structure in the torque converter 1 . figure 2 It is an enlarged view of the vicinity of the lockup mechanism portion 16 of the torque converter 1 . image 3 It is an enlarged view around the rotation axis X of the torque converter 1 .

[0091] Such as figure 1 As shown, a torque converter 1 includes a fluid transmission unit 15 and a lockup mechanism unit 16 in a torque converter case 2 composed of a pump impeller 3 and a torque converter cover 4 .

[0092] In the fluid transmission part 15 , the pump impeller 3 and the turbine wheel 5 are provided so as to be relatively rotatable on a common rotation axis X, and the stator 6 is located between the pump impeller 3 and the turbine wheel 5 .

[...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap