A method for optimizing hydraulic fracturing proppant parameters

An optimization method and hydraulic fracturing technology, applied in design optimization/simulation, earthwork drilling and production, data processing applications, etc., can solve the problems of few proppants, limitations of type selection results, and difficulty in truly reflecting the formation fluid conductivity, etc. problem, to achieve the effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

[0029] A hydraulic fracturing proppant parameter optimization method, it comprises the following steps:

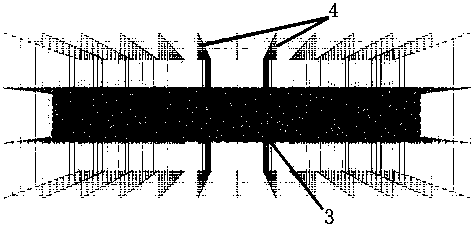

[0030] S1. According to the geological conditions and mechanical characteristics of the rock formation, establish a rock formation-proppant-rock formation physical model that restores the true size of the proppant. The specific method of establishing the rock formation-proppant-rock formation physical model is as follows: establish a triaxial test model, make the rock formation and proppant model present different macroscopic physical properties by changing the physical parameters of the particles in the model, and make the macroscopic physical properties of the triaxial test model Checking with the macroscopic mechanical parameters of the laboratory triaxial test can determine the physical param...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com