A kind of oblique pull cutting machine

A cutting machine and oblique pulling technology, applied in metal sawing equipment, metal processing equipment, manufacturing tools, etc., can solve the difficulty of locking the crank arm, the difficulty in adjusting the angle between the crank arm and the working plate, and the difficulty in adjusting the angle of the working plate base, etc. problem, to achieve the effect of high adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

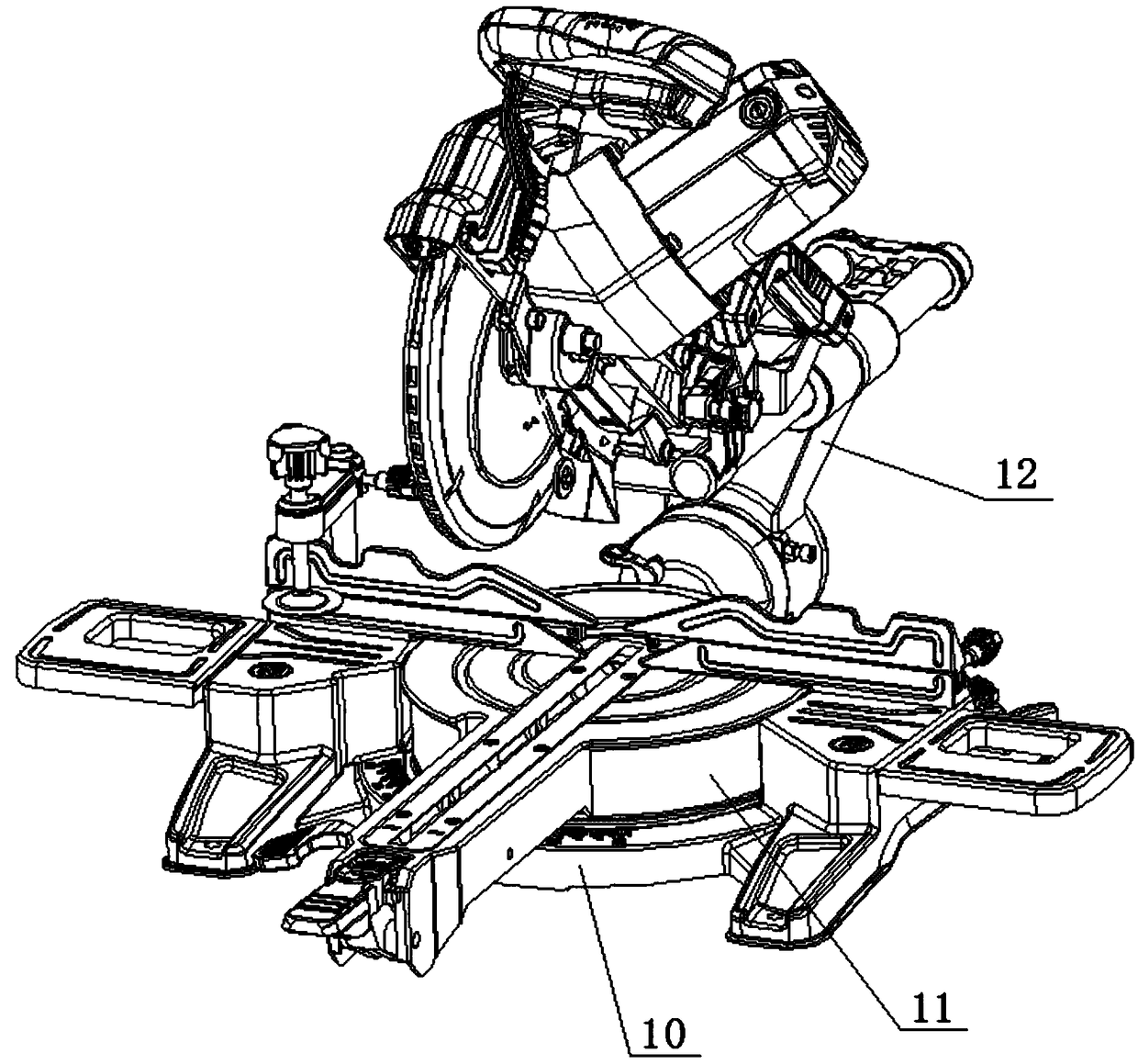

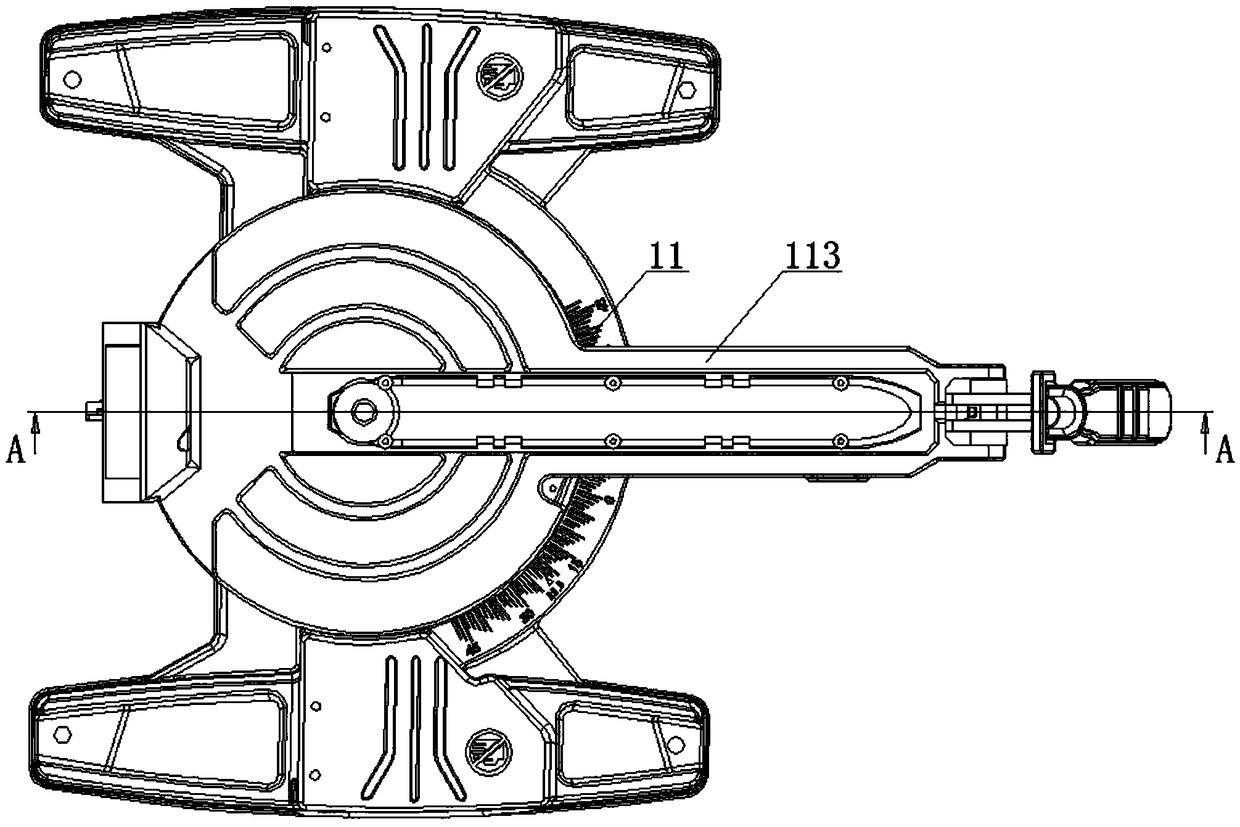

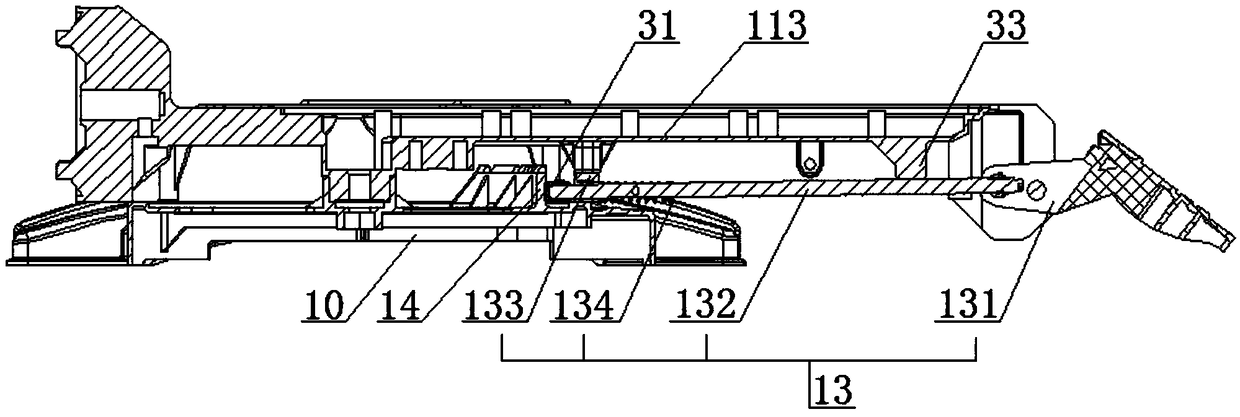

[0045] A kind of oblique pull cutting machine, such as Figure 1-18 As shown, it includes a base 10, a working disk 11 and a curved arm 12. The working disk 11 is installed on the base 10. The working disk 11 includes a first disc 111, a second disc 112 and a rotating handle 113. The second disc 112 and Rotating handles 113 are all fixed on the outer peripheral sidewall of the first disc 111, the second disc 112 and the rotating handle 113 are arranged oppositely, the curved arm 12 is connected with the second disc 112, and the working disc 11 is provided with a locking work. The first locking device 13 of the disc 11 and the base 10, the first locking device 13 includes a first locking button 131 and a first locking rod 132, the first locking button 131 is connected with the first locking rod 132, and the base 10 is fixed with a vertically upwardly protruding positioning piece 14, press the first locking button 131, and the top of the first locking rod 132 presses against the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com