Garbage can

A trash can and lid technology, applied in the field of trash cans, can solve the problems of large volume of domestic garbage, easy to fall out of garbage, and less garbage, and achieve the effect of convenient movement, small occupied space, and increased stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

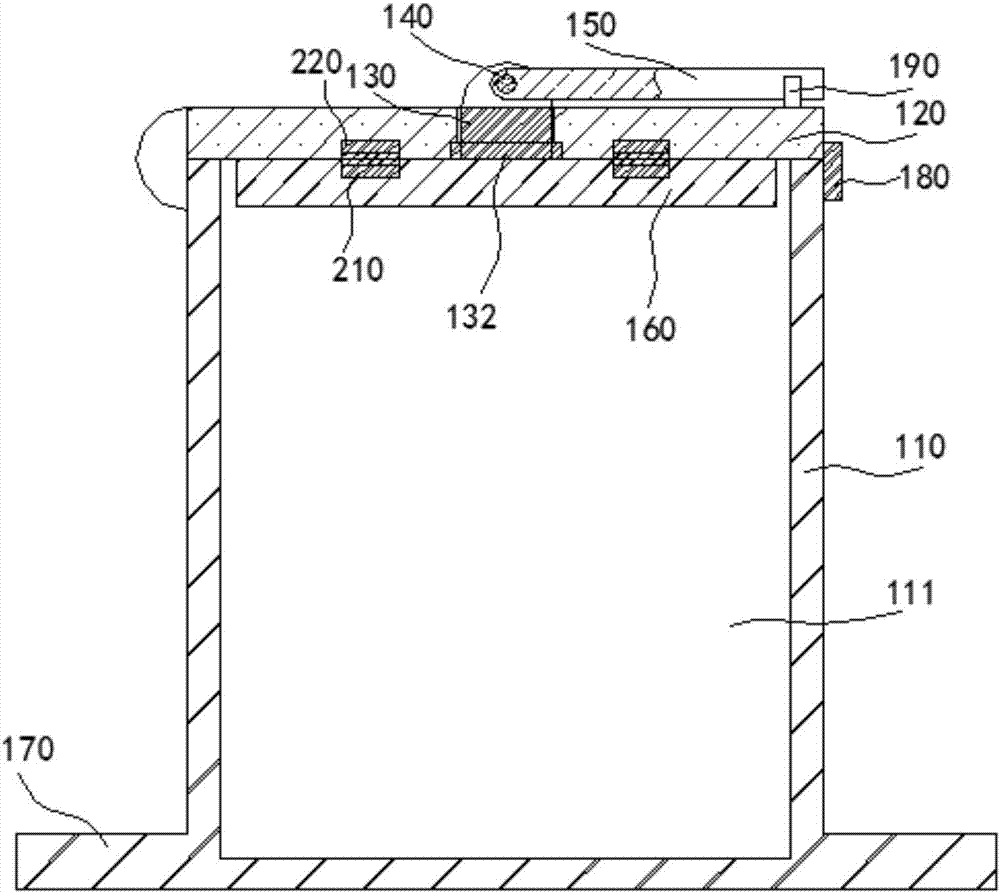

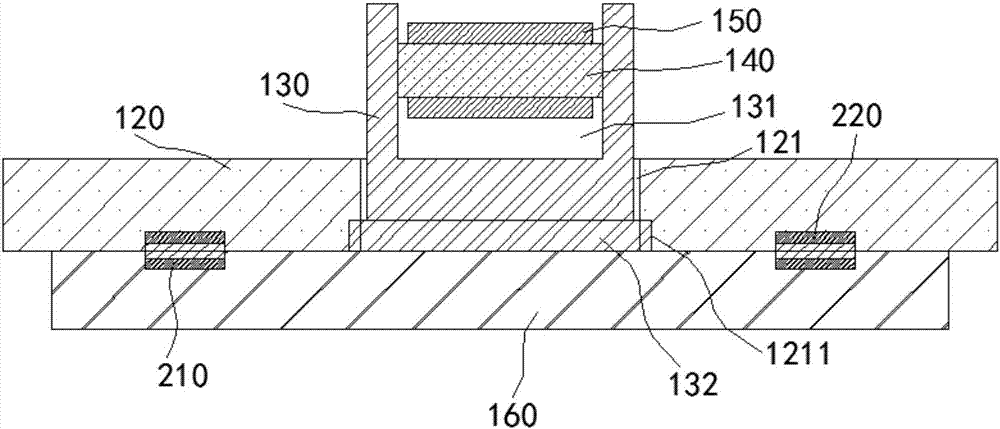

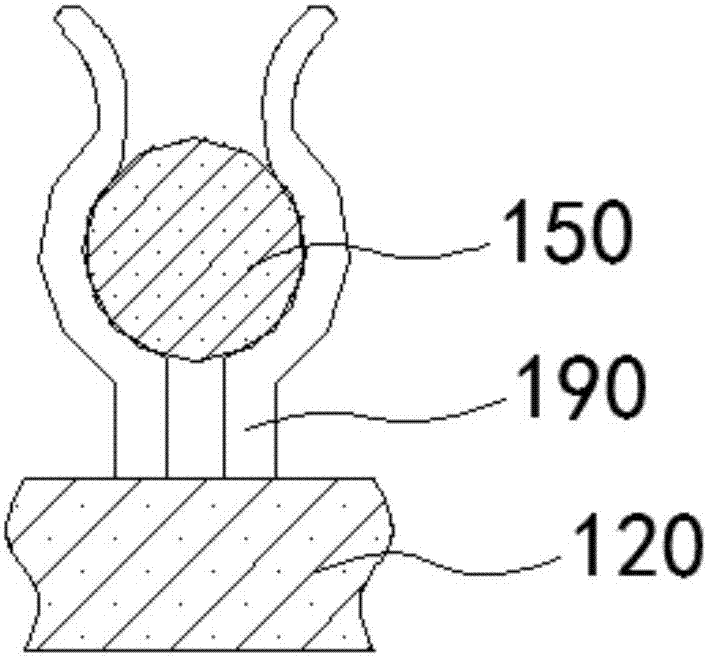

[0027] Such as figure 1 , figure 2 and image 3 As shown, the present embodiment provides a trash can, including a barrel body 110, a barrel cavity 111 is arranged in the barrel body 110, a barrel cover 120 is arranged at the mouth of the barrel cavity 111, and one end of the barrel cover 120 is hinged on the outer wall of the barrel body 110 On; the center of the bung 120 is provided with a through hole 121, the lower opening of the through hole 121 is a threaded hole 1211 and the diameter of the threaded hole 1211 is larger than the diameter of the through hole 121, a round rod 130 can move through the through hole 121 and the top is provided with Through groove 131, a horizontal shaft cylinder 140 is arranged between the two side walls of the through groove 131, and a movable rod 150 is rotatably sleeved on the horizontal shaft cylinder 140; the bottom end of the round rod 130 is circumferentially provided with an external thread 132, and the external thread 132 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com