Improved stainless steel hanger rail tackle

A stainless steel, improved technology, applied in the direction of load block, track system, load suspension components, etc., can solve the problems of short service life, structural toughness, corrosion resistance, poor wear resistance, easy to fall off, etc., to achieve corrosion resistance and Excellent wear resistance, eliminate production safety hazards, and eliminate impact hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

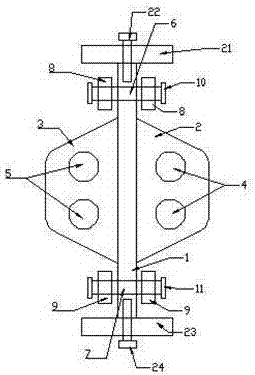

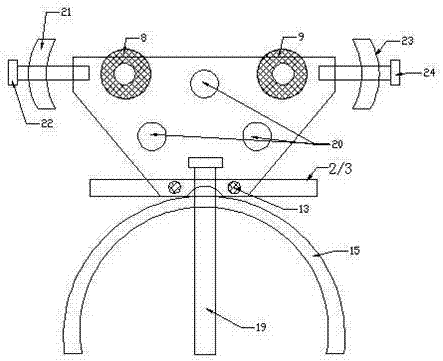

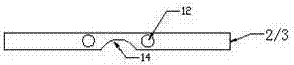

[0020] Such as figure 1 , figure 2 , image 3 and Figure 4 The shown improved stainless steel rail block consists of a support plate body 1, a first ear plate 2 and a second ear plate 3 symmetrically arranged on both sides of the support plate body 1, and the first ear plates 2 are arranged respectively. , a group of first positioning holes 4 on the second ear plate 3, a group of second positioning holes 5, and cooperate with the first ear plate 2 and the second ear plate 3 respectively to pass through the first positioning holes 4, the second The adjustment support assembly installed in the positioning hole 5 is composed of the first sliding assembly and the second sliding assembly symmetrically arranged at both ends of the support plate body 1; the adjustment support assembly includes the first ear plate 2 and the second ear plate 3 respectively. Ear plate positioning holes 12, wherein, the first ear plate 2 and the second ear plate 3 are respectively connected to both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com