Intelligent system and replacing method for replacing gear case high-speed shaft in air

An intelligent system and high-speed shaft technology, applied in the field of intelligent systems, can solve the problems of high maintenance plan cost and long maintenance time, and achieve the effect of avoiding long-distance transportation, easy operation and reducing risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

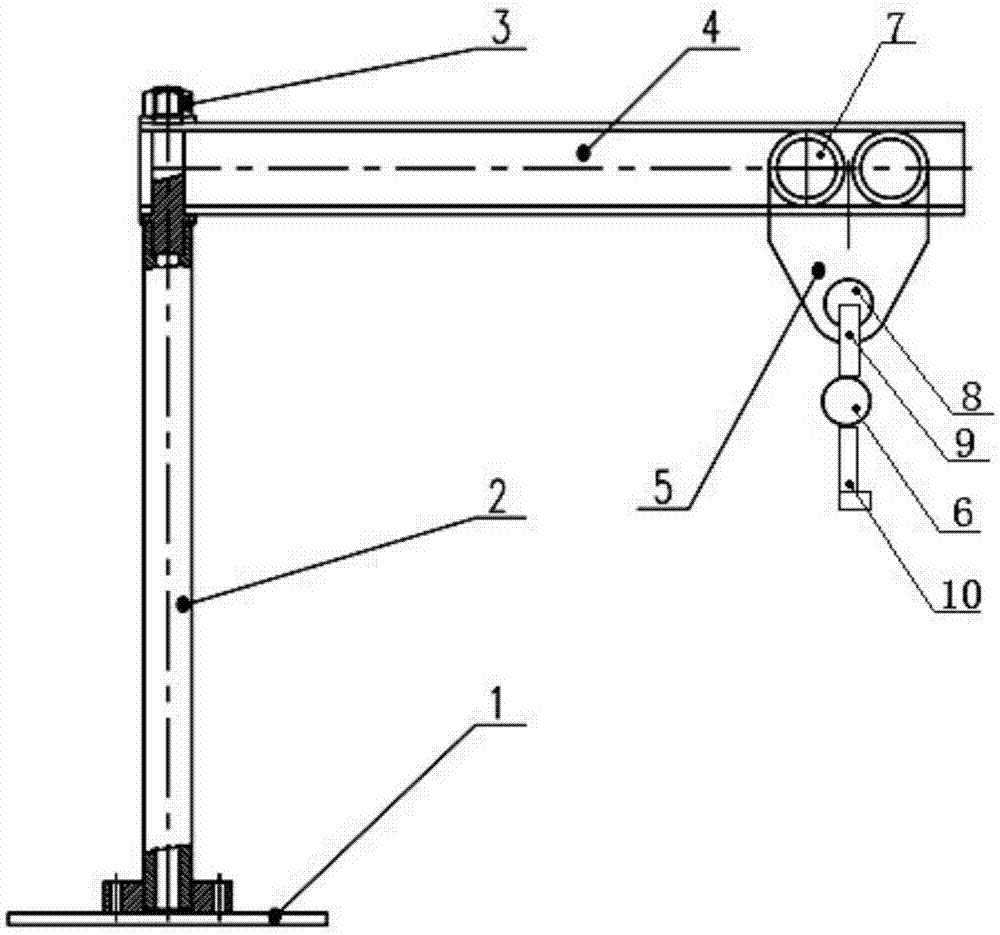

[0018] Such as figure 1 The shown intelligent system for replacing the high-speed shaft of the gearbox in the air includes a cantilever crane base 1, a cantilever crane column 2 fixed on the cantilever crane base 1, and a slide rail 4 fixed with the cantilever crane column 2 through a fixing bolt 3 ; The track trolley 5 is installed on the slide rail 4; the chain block 6 is suspended on the track trolley 5; the wheels 7 of the track trolley 5 are clamped on the slide rail; Hanging hole 8; the chain block 6 includes an upper hook 9 and a lower hook 10; the upper hook 9 is articulated in the hanging hole 8; the lower hook 10 is articulated in a high-speed shaft special tooling (not shown )superior.

[0019] The special tooling (not shown) for the high-speed shaft is fixed to the high-speed shaft of the fan gearbox.

[0020] The cantilever suspension base 1 is installed at the observation window on the top of the gearbox.

[0021] The replacement method of the intelligent syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com