Design method of axial symmetry adjustable ultrasonic air inlet way based on flexible center body

A design method and air intake technology, applied in computing, mechanical equipment, sustainable transportation, etc., can solve the problem that the design method has not been published.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

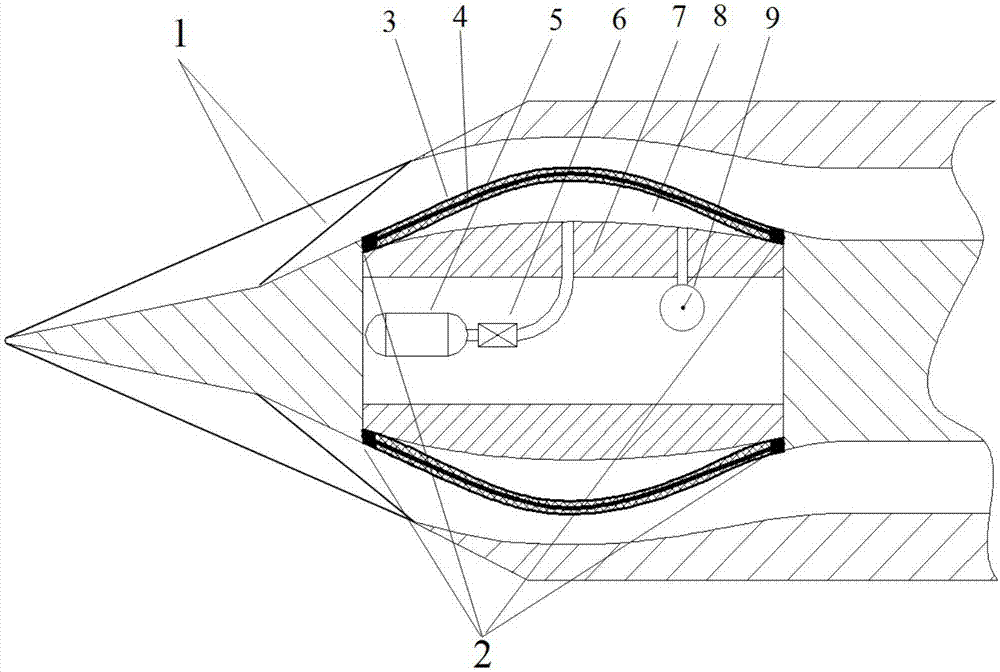

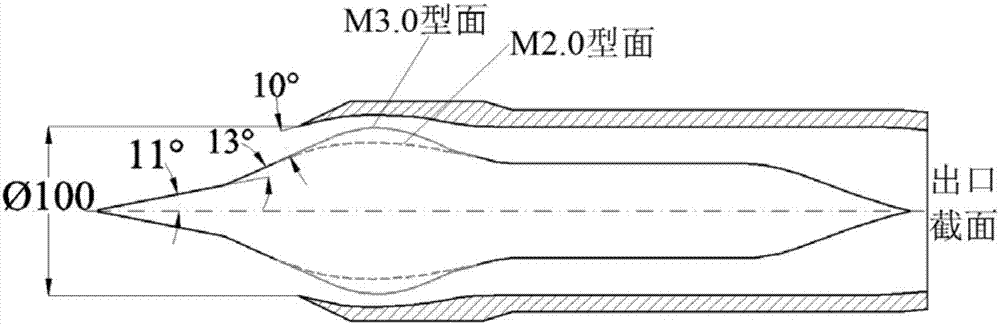

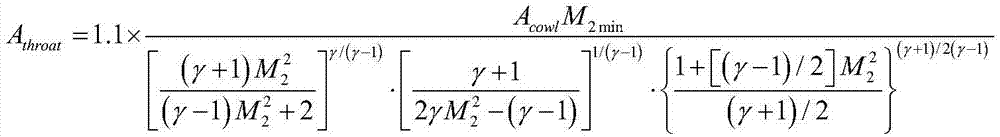

[0059] Such as figure 2 As shown, an axisymmetric supersonic inlet based on a flexible central body with a working Mach number ranging from 2.0 to 3.0, the inlet capture diameter is 100 mm, two-stage external compression cones are used, and the airflow deflection angles are 11° and 13° respectively , the initial angle of the lip cover is 10°, and the design of the flexible central body is adopted. The throat height of the inlet is 14.3mm when the inlet works at Mach 2.0, and the throat height of the inlet is 8.5mm when the inlet is at Mach 3.0. The comparative axisymmetric inlets have the same external compression and capture diameters, while the throat height is fixed at 14.3 mm. Table 1 compares the recovery of the critical total pressure at the outlet of the two inlets when they work at Mach numbers 2.0 and 3.0. It can be seen that after the introduction of the flexible central body design, the total pressure recovery coefficient of the inlet port at Mach number 3.0 has b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com