Method for obtaining high-efficiency low-stress grinding process parameters of ultra-high-strength steel

A technology of ultra-high-strength steel and process parameters, which is applied in the field of precision and ultra-precision grinding, can solve the problems of large surface residual stress and low grinding efficiency, and achieve high reliability and long life, and prevent grinding cracks Generate and analyze method-reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The patent of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

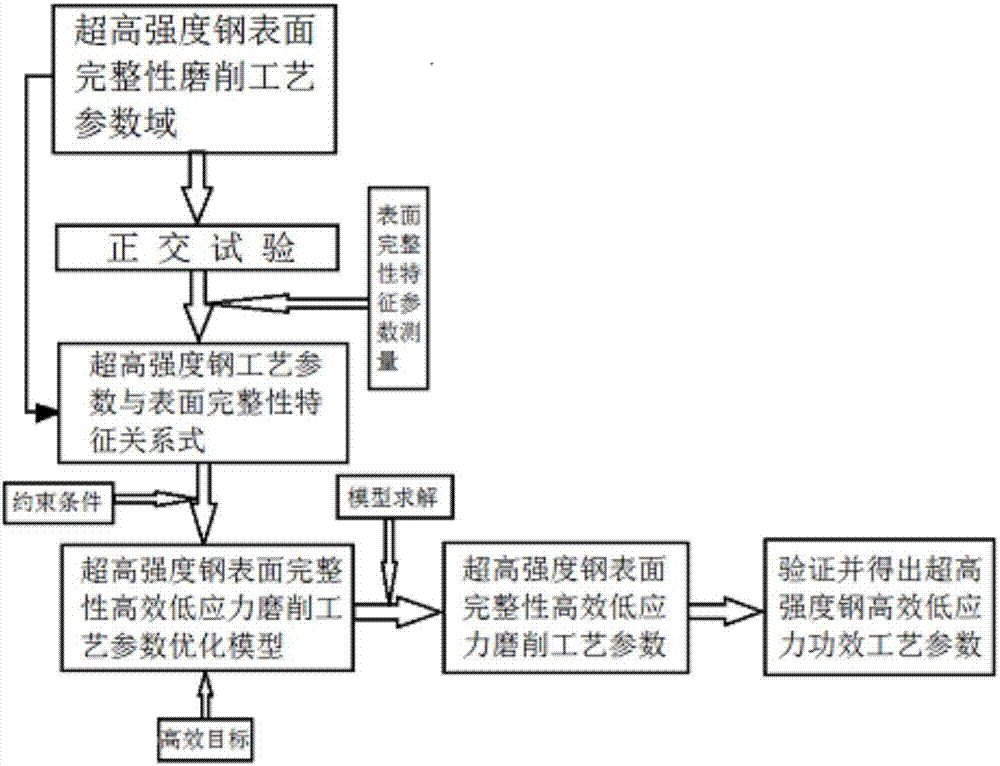

[0041] The invention discloses a method for obtaining process parameters of high-efficiency and low-stress grinding of ultra-high-strength steel, such as figure 1 As shown, the specific steps are as follows:

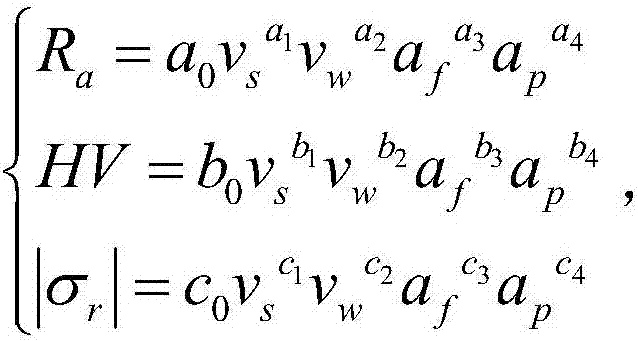

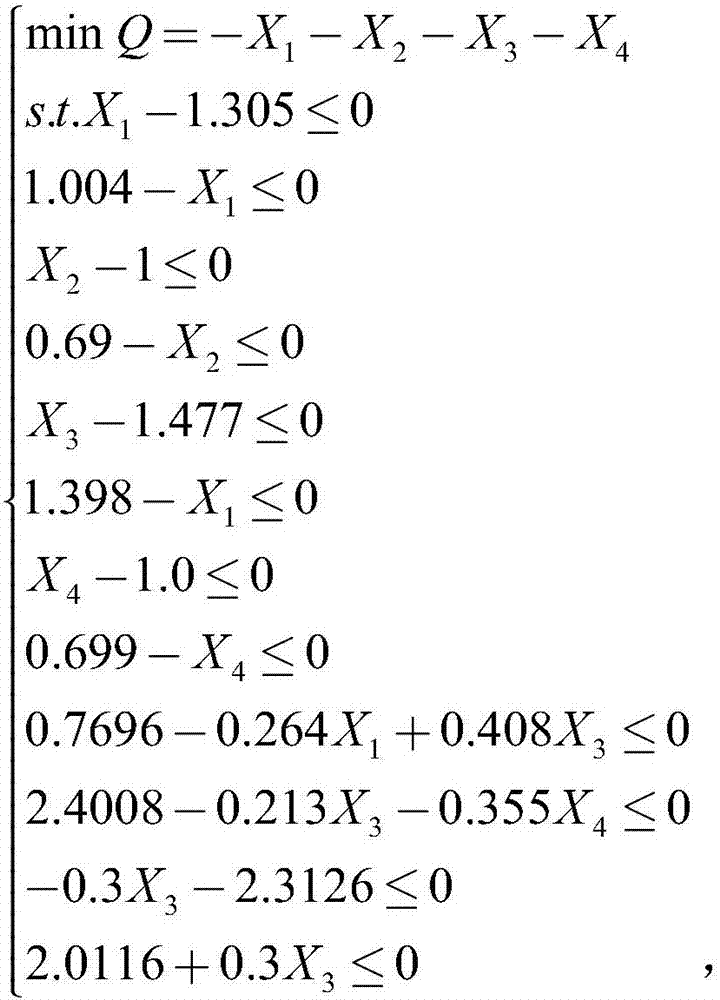

[0042] Step 1. Establish the ultra-high-strength steel surface integrity grinding process parameter domain, and conduct an orthogonal test to establish the relationship between the ultra-high-strength steel surface integrity grinding process parameters and surface integrity characteristics through the orthogonal test. The specific steps as follows:

[0043] Step 1.1: According to the aviation manufacturing engineering manual, experience or literature, formulate the grinding process parameter domain of ultra-high-strength steel Aermet100 surface integrity, where the grinding method adopts cylindrical grinding, the type of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com