pollen dry powder duster

A duster and pollen technology, which is applied in the fields of plant genetic improvement, agriculture, and botanical equipment and methods, can solve the problems of easy blockage and deposition of pollen, achieve approximately controllable spraying amount, avoid blockage or deposition, and improve The effect of fruit quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

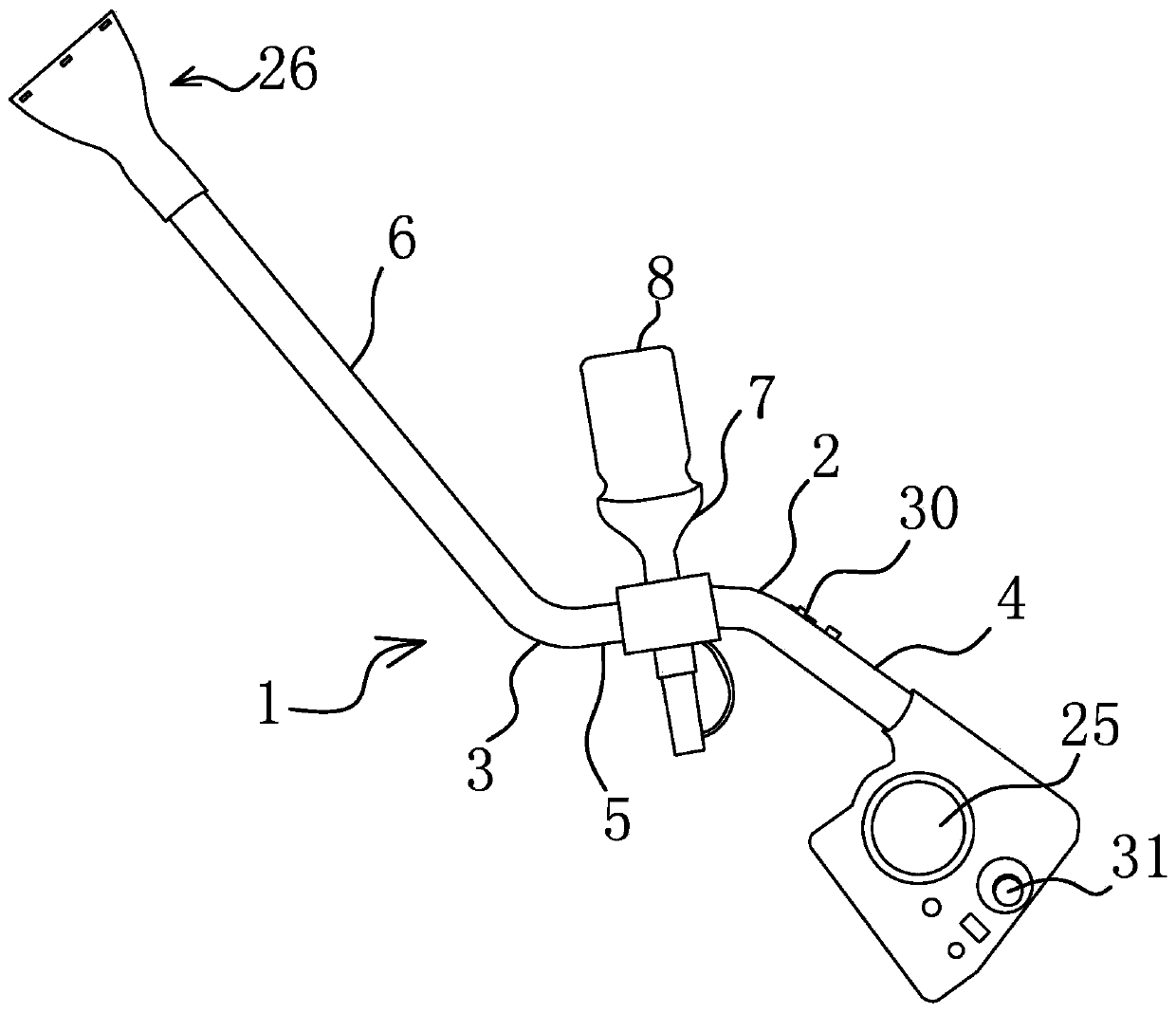

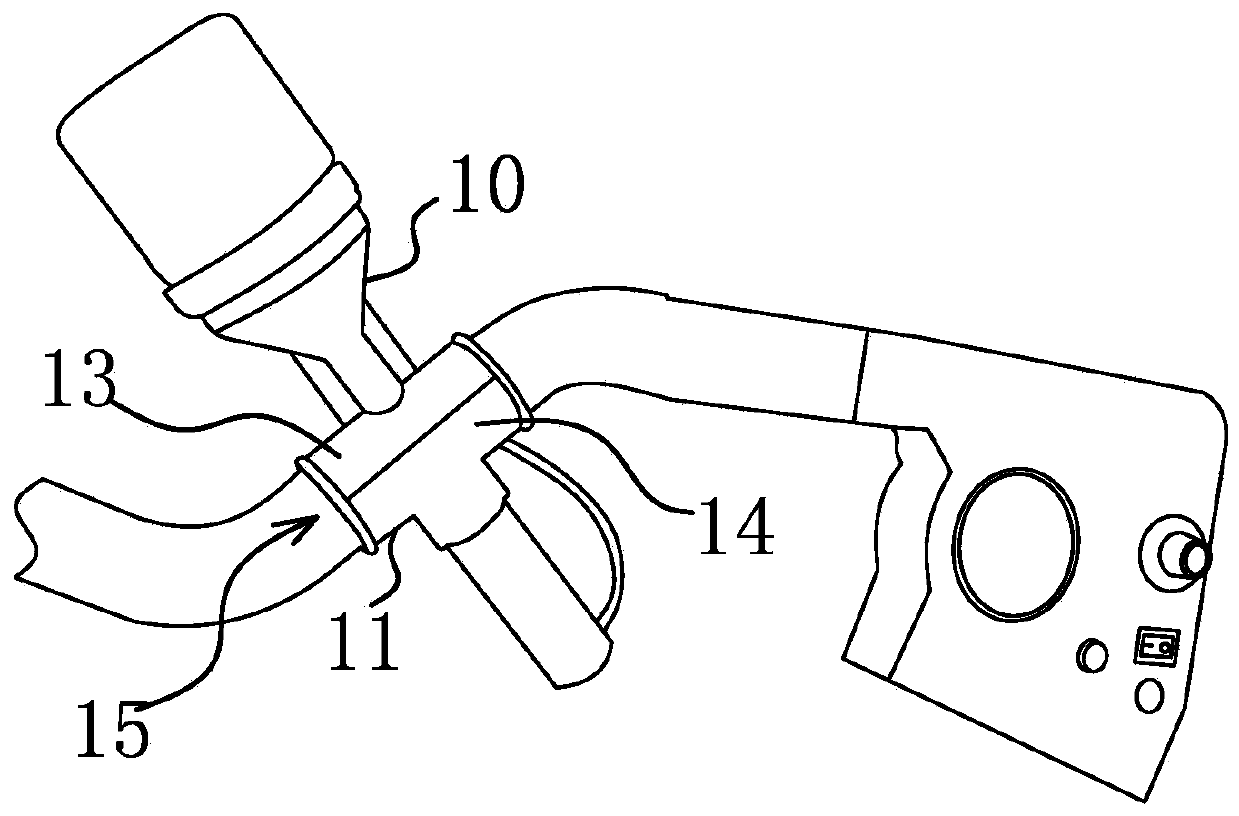

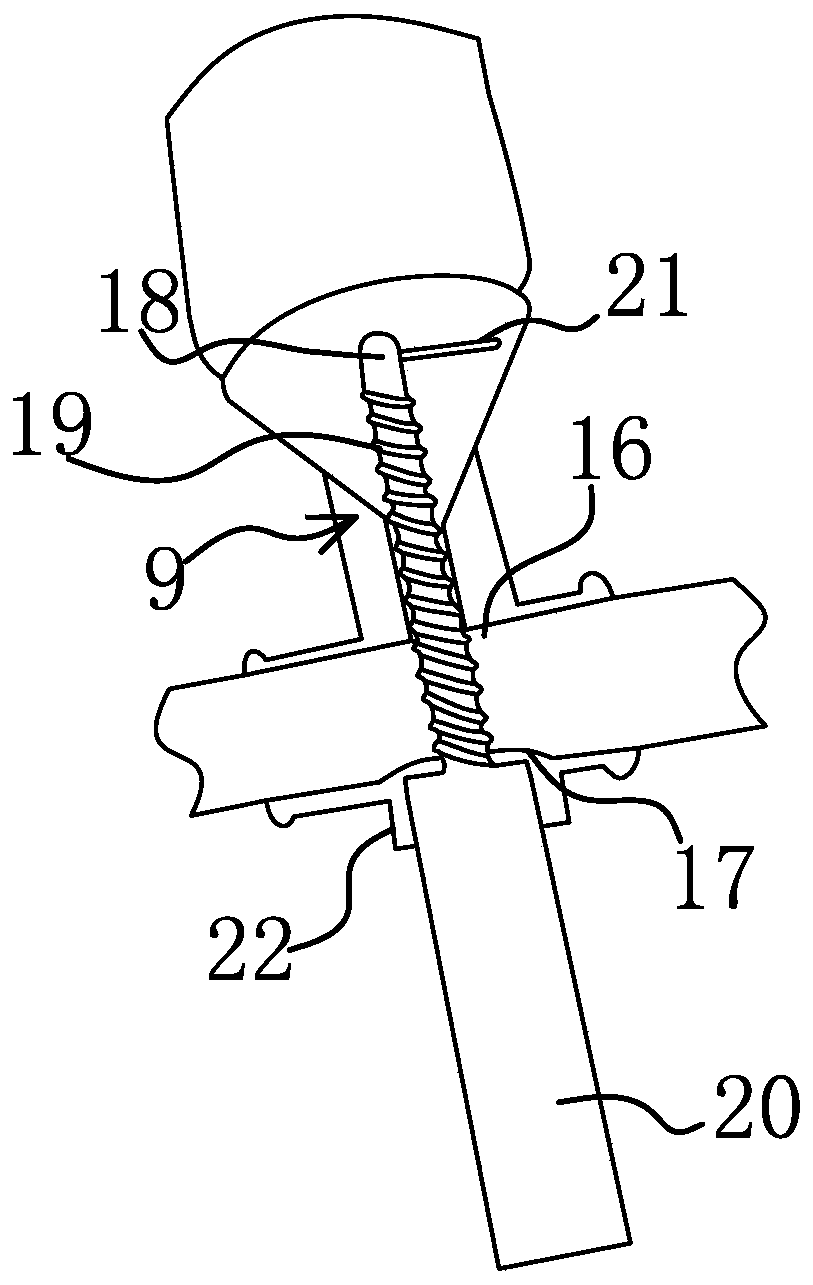

[0029] Such as Figure 1-Figure 7 As shown, the pollen dry powder sprayer includes a conveying pipe 1 for conveying pollen, and it is characterized in that the conveying pipe 1 has a first bending portion 2 and a second bending portion 3 in sequence, and the first bending portion The bending part 2 and the second bending part 3 divide the conveying pipe 1 into the pollen conveying driving section 4, the pollen loading section 5, and the pollen spraying section 6 in turn. The bending of the first bending part 2 and the second bending part 3 is not without Meaning, the bent part can be used as a transport buffer, so that the pollen is buffered during the transport process, and when the transport is stopped, the bent part can be used as the drop point of the pollen, so that it will not accumulate in the same place and form a pile.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com