Nail making machine for producing diagonal row nails with small wire diameter

A nail making machine and oblique row technology, applied in the directions of nails, mechanical equipment, connecting components, etc., can solve the problem that the 90-degree inner angle cannot be reinforced, and achieve the effects of improving product quality, high component precision, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

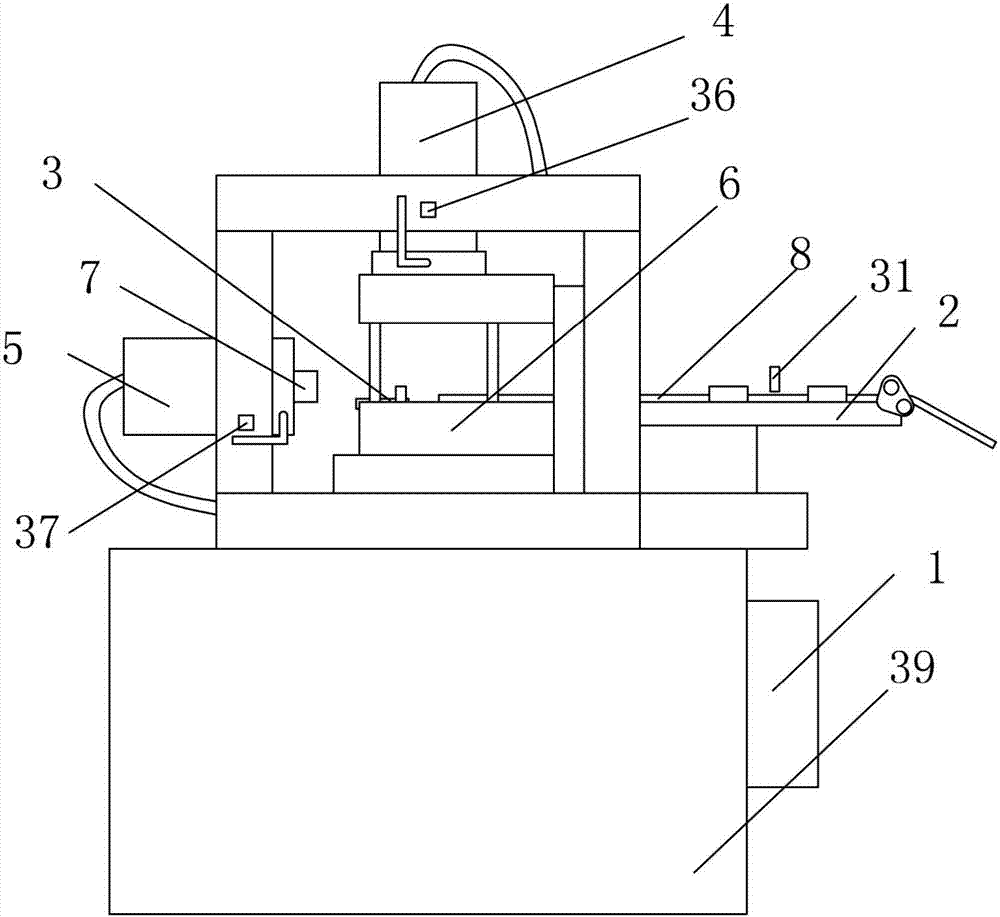

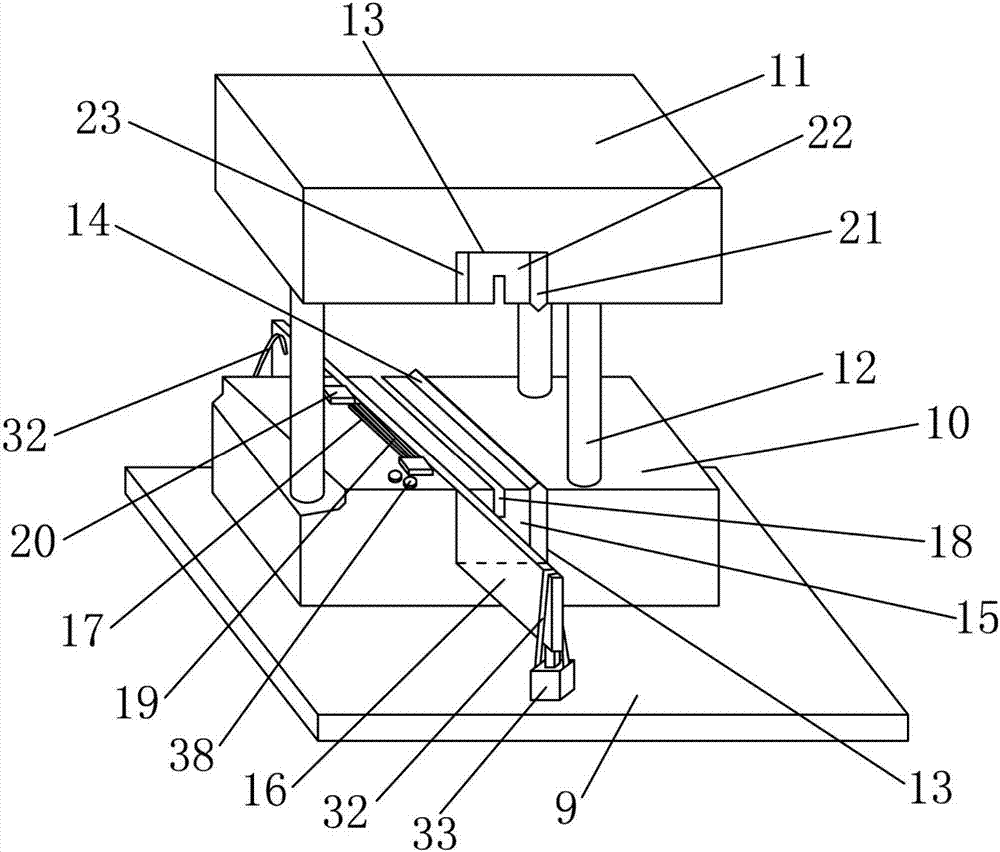

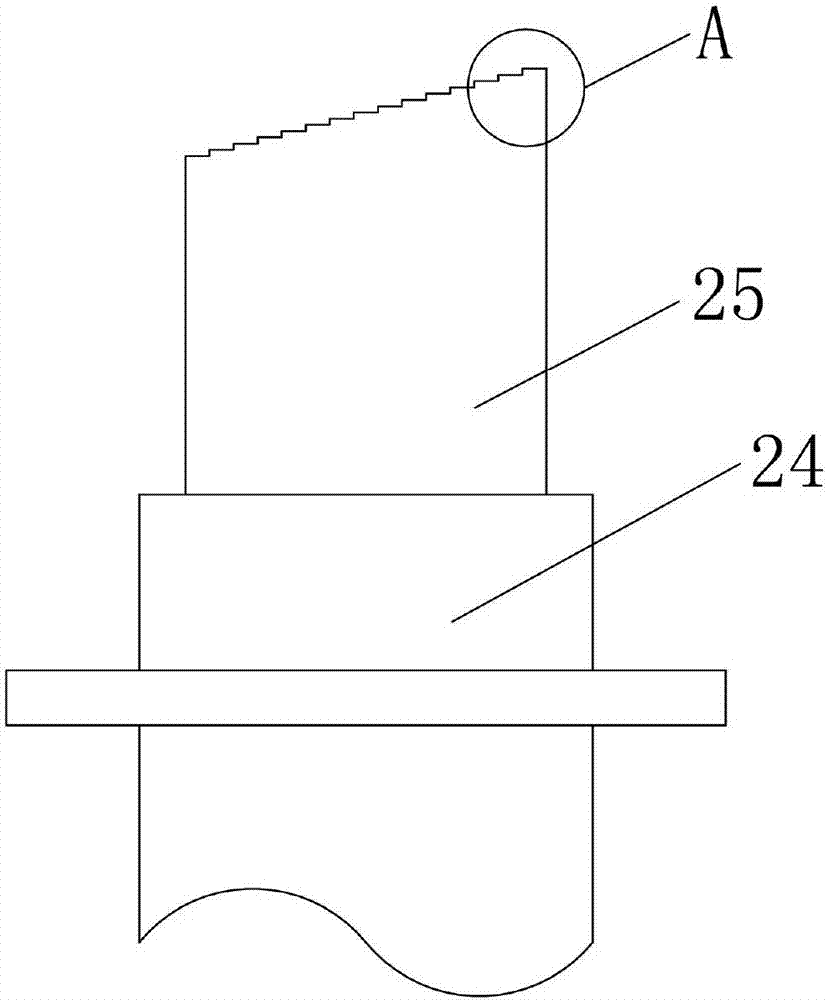

[0028] Embodiment: a kind of nail making machine that is used to produce small-diameter oblique row nails, such as Figure 1-6 As shown, it includes a frame, and the frame is provided with a feeding mechanism, a cutting punching mechanism, a nail cap forming mechanism, a discharging mechanism, a PLC controller, a first driving mechanism and a second driving mechanism, and the feeding mechanism is provided with There is a nail strip composed of a plurality of flat steel wires side by side, a first sensor is arranged above the nail strip, and the feeding mechanism is arranged at the front end of the cutting stamping mechanism, and the nail strip is transported to the cutting stamping mechanism Among them, the cutting and stamping mechanism cuts and stamps the strip of nails according to the size requirements, and the nail cap forming mechanism is arranged at the rear end of the cutting and stamping mechanism to stamp one side of the strip of nails after cutting and stamping to fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com