Counter-gravity casting riser tube positioning mechanism

A technology of anti-gravity casting and positioning mechanism, which is applied to casting equipment, manufacturing tools, and equipment for feeding molten metal into molds, etc., and can solve problems such as deviation of riser pipes and gaskets, and pouring failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

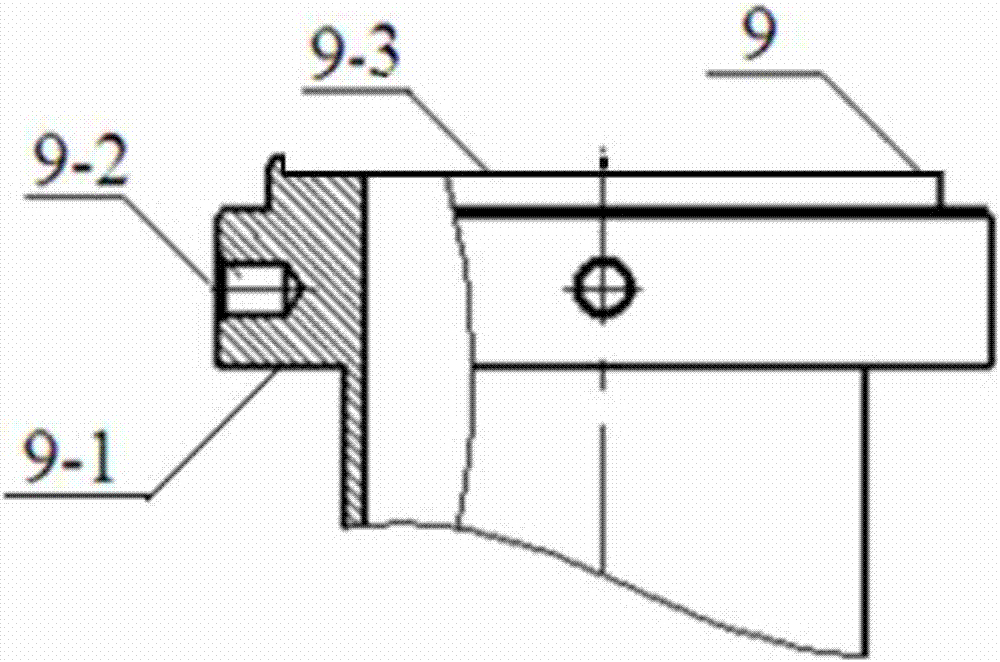

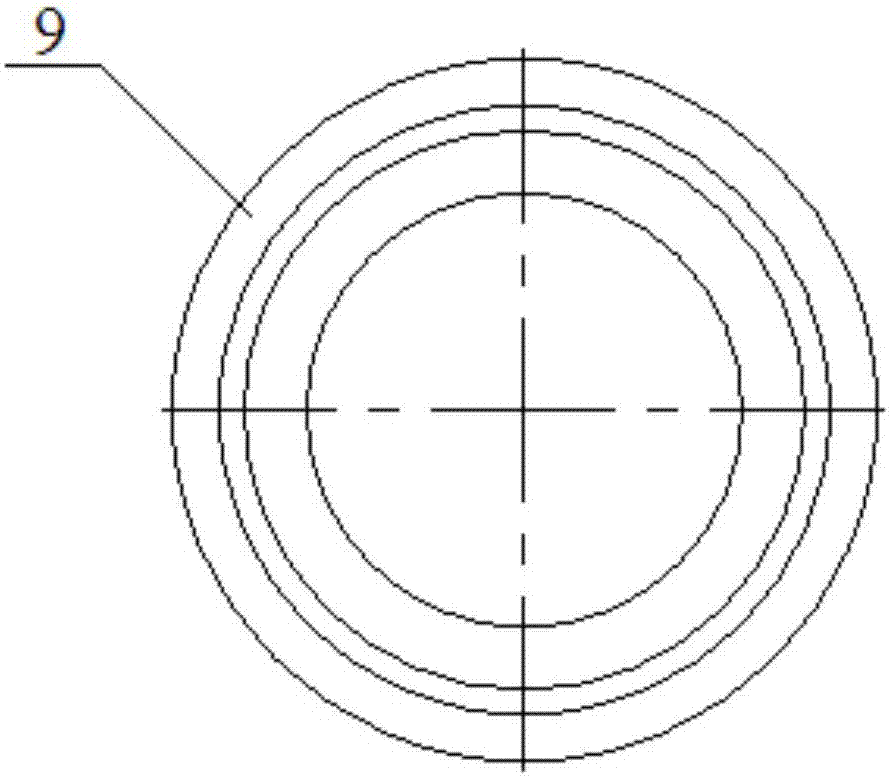

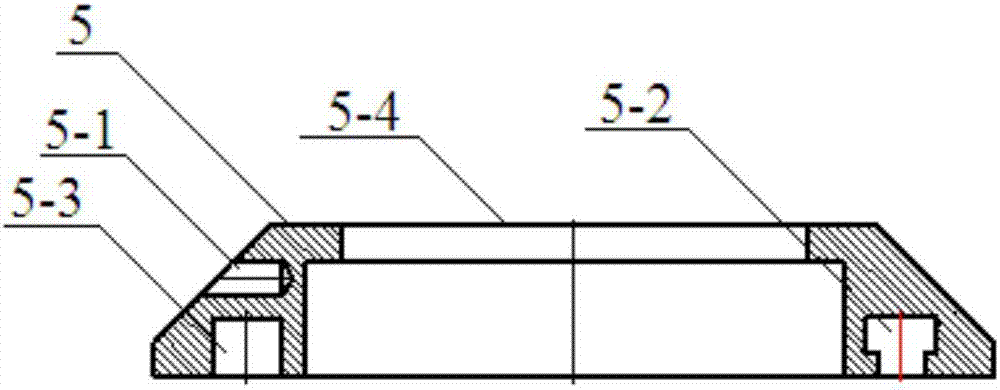

specific Embodiment approach 1

[0017] Specific implementation mode 1: In this embodiment, the anti-gravity casting riser pipe positioning mechanism is set up in sequence from top to bottom with the mold 1, the upper sealing gasket 4 of the riser pipe, the positioning ring 5, the middle partition plate 6, the positioning bolt 7, and the riser pipe The lower sealing gasket 8 and the riser pipe 9, the riser pipe 9 is fixed on the intermediate partition 6 by the positioning ring 5 and the positioning bolt 7, the upper end of the riser pipe 9 is provided with a flange 9-1, and the flange 9-1 The side surface is provided with a hoisting port 9-2, the top of the flange 9-1 is provided with a limit groove 9-3, the sealing gasket 4 on the riser pipe is matched with the limit groove 9-3, and the upper part of the positioning ring 5 is a conical platform, positioning The lower section of the ring 5 is a cylindrical platform, and a hoisting hole 5-1 is provided on the side of the conical platform. The cavity 2 is locate...

specific Embodiment approach 2

[0018] Embodiment 2: This embodiment differs from Embodiment 1 in that the positioning ring 5 is provided with a central stepped hole 5-4, and the flange 9-1 cooperates with the central stepped hole 5-4. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0019] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that there are four positioning slots 5-2 and positioning bolt inlet and outlet 5-3 under the cylindrical platform, and the positioning slots 5- 2 communicate with the set bolt inlet and outlet 5-3. Others are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com