Gun exchanging plate

A technology for changing gun disks and inclined surfaces, which is applied in the direction of manipulators and manufacturing tools to achieve good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

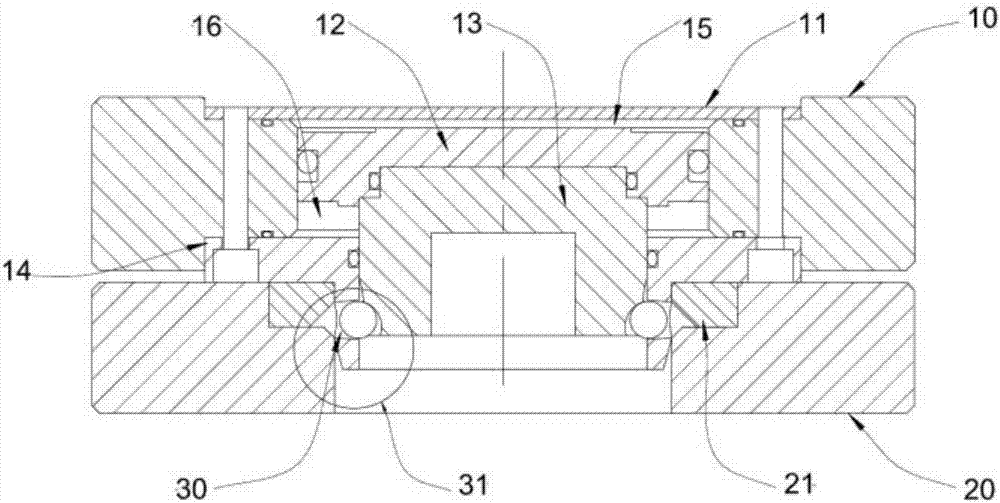

[0043] This embodiment discloses a gun changing disc, which includes a tool side and a main body side. Wherein, the main body side includes: a main body plate, a recess is provided on the main body plate, and a protrusion is arranged in the recess; a piston, the piston is a cavity structure with one end open and one end closed, and the piston is movably mounted on the protrusion. A ring of steel balls is provided at the opening end, and a first sealing cavity is formed between the piston and the main body plate; the piston cover is located in the inner cavity of the piston, and is fixed on the protrusion of the recess, forming a second sealing cavity with the piston; The flange includes an annular sheet structure and an extension part, the annular sheet structure is fixedly connected to one end of the main body plate, the extension part is arranged on the inner side of the annular sheet structure, and the extension part extends away from the main body plate, and the extension p...

Embodiment 2

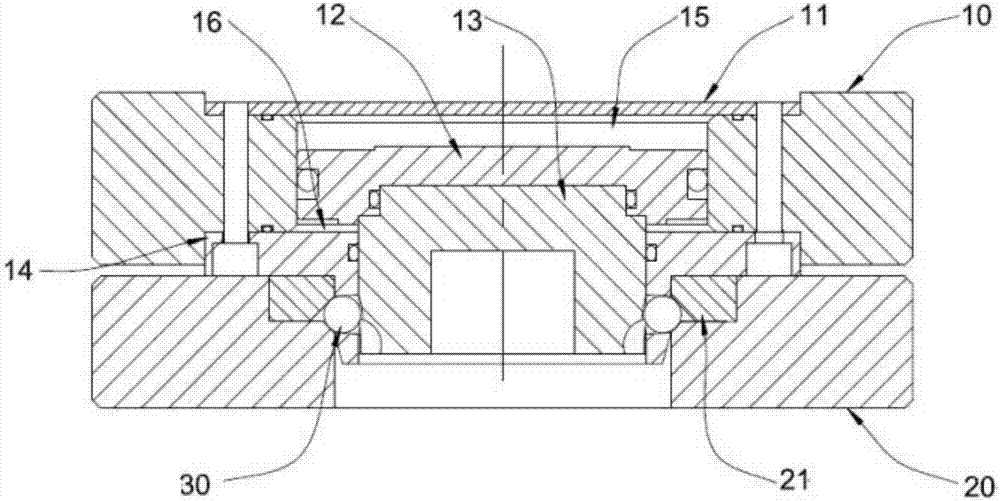

[0049] Embodiment 2 discloses another specific embodiment for changing the gun disk. Its structure is basically the same as Embodiment 1. The difference is that in this embodiment, an annular groove is provided on the tool plate. When the tool side is placed On the main body side, the end surface of the tool plate outside the annular groove is attached to the end surface of the annular sheet structure of the flange, and the extension of the flange and the opening end of the piston extend into the annular groove. Specifically, the bottom of the annular groove is provided with a through hole.

[0050] The annular groove in this embodiment can guide the movement of the piston to a certain extent, making the movement of the piston more stable, thereby ensuring the smooth locking and separation of the tool side and the main body side, and the through hole at the bottom of the groove is convenient for the piston When moving in the groove, the air pressure in the groove is too high t...

Embodiment 3

[0052] Embodiment 3 discloses another specific embodiment of the gun changer, its structure is basically the same as Embodiment 1, the difference is that, in this embodiment, the second end of the extension part is provided with a third slope, and the third The inclined plane and the second inclined plane are located on the same side of the extension part, and the third inclined plane is opposite to the inclined direction of the second inclined plane. When the tool side is put into the main body side and is in a loose state, the third slope is located outside the steel ball, and the third slope can form a certain protection for the steel ball.

[0053] Specifically, the main body plate is provided with a fourth slope, the fourth slope is located inside the annular groove, and the fourth slope is facing the outside of the ring groove, and the fourth slope is opposite to the first slope and the direction of inclination is opposite. When the tool side is separated from the main b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com