The method of determining the pouring temperature for finite element calculation according to the measured value of pouring temperature

A technology of pouring temperature and finite element, applied in calculation, computer-aided design, special data processing application, etc., can solve the problems of finite element analysis result error and inability to guarantee the scientific accuracy of tracking analysis, so as to improve scientific accuracy and guarantee The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0046] The method for determining the pouring temperature for finite element calculation according to the pouring temperature measurement value disclosed by the present invention includes:

[0047] 1. Heat of hydration temperature rise during pouring.

[0048] The equivalent hydration exotherm time is:

[0049]

[0050] Among them, T c is the initial temperature of the adiabatic temperature rise test block; T 1 It is the time interval from the end of concrete unloading and vibrating to the end of pouring of pavement layer; is the equivalent hydration exothermic time, that is, the time for the adiabatic temperature rise test; Δτ is the pavement interval time.

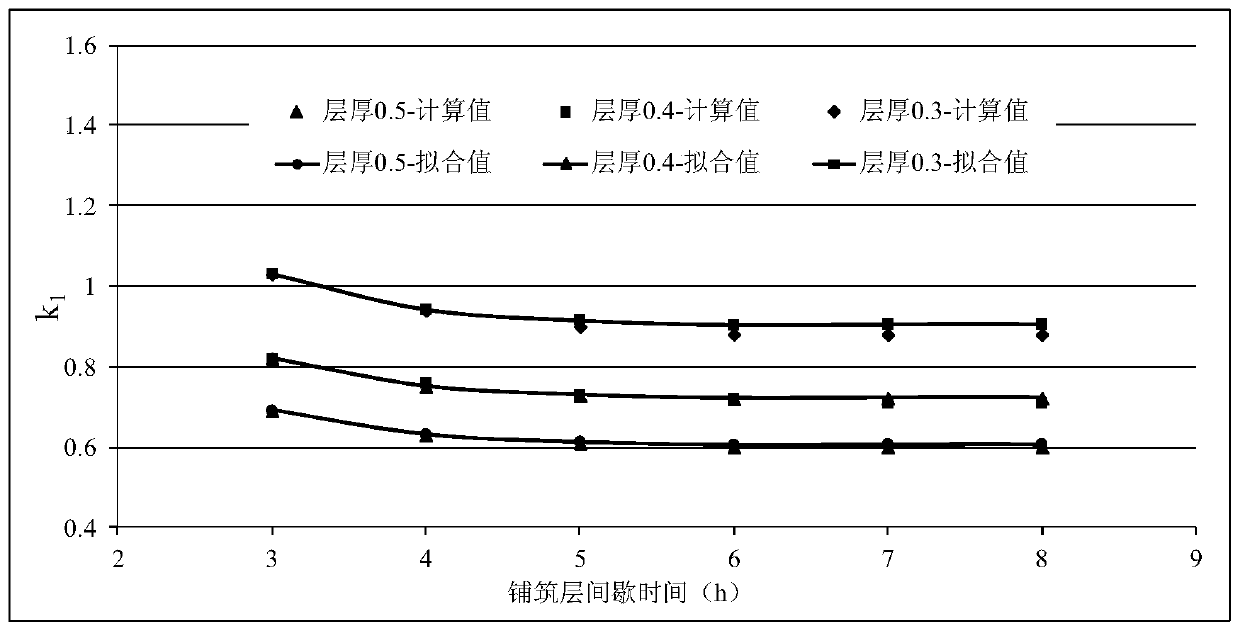

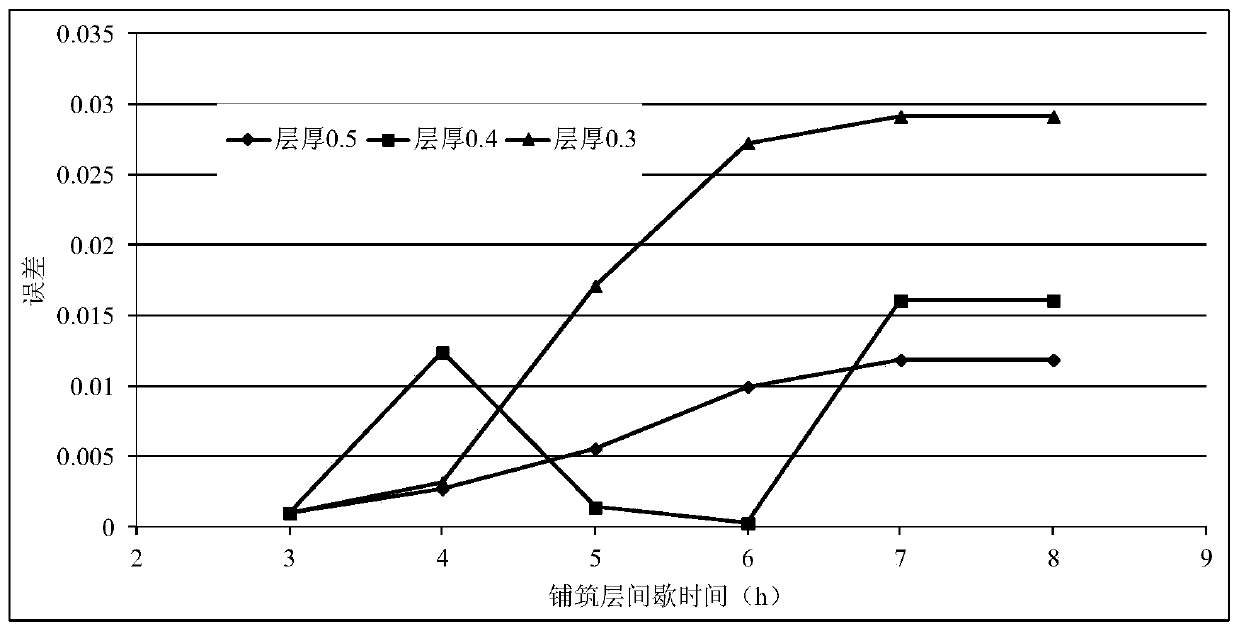

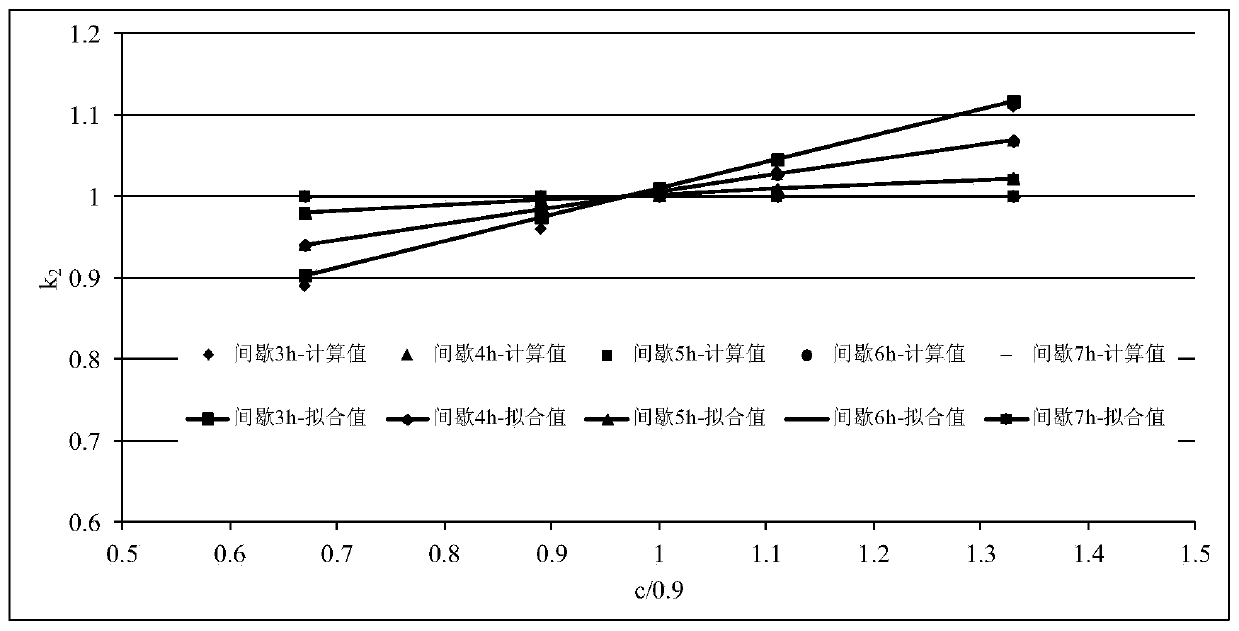

[0051] The temperature rise caused by the exotherm of hydration is Preferably derived directly from experimental data on the basis of using the equivalent exotherm of hydration time. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific heat capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com