Multipurpose combined ground clamp module

A grounding clamp and combined technology, which is applied in the direction of winding connectors, electrical connection seats, overhead lines/cable equipment, etc., can solve the problems of resource waste, wire clamp falling off, shaking, etc., and achieve good clamping of wires and contact The effect of stable surface and not easy to loosen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1, the clamp body of this embodiment is installed horizontally (the clamp body is arranged perpendicular to the wire), and the clamping mold clamps the wire from the upper and lower sides of the wire.

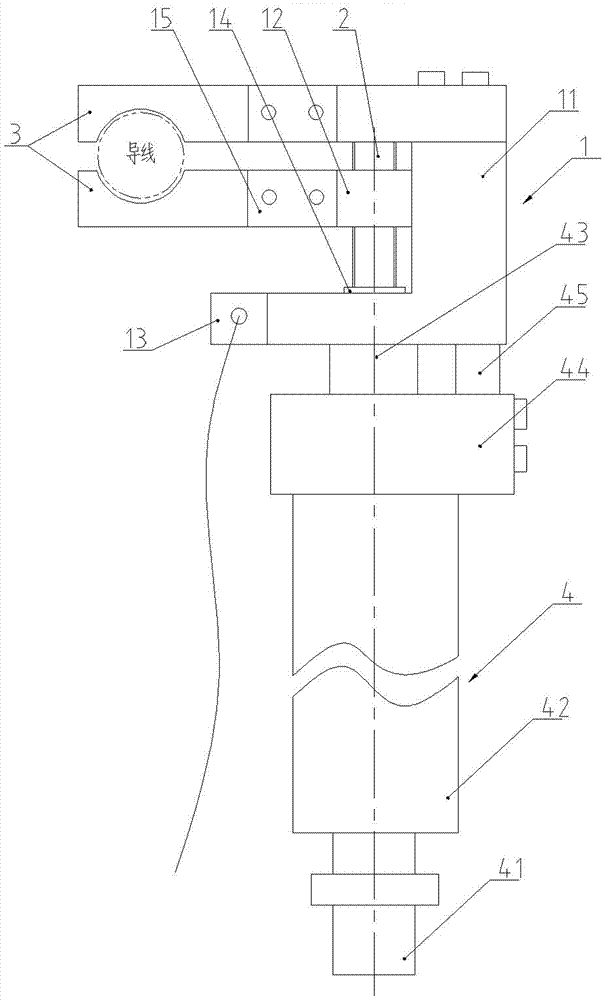

[0028] Such as figure 1 As shown, the multipurpose combined ground clamp assembly provided in this embodiment includes a clamp body 1 , a screw 2 , a clamping mold 3 , and an operating rod 4 .

[0029] Such as figure 1 , figure 2 As shown, the clamp body 1 includes a fixed member 11 and a rectangular movable block 12 . The shape of the fixing member 11 is a C-shape in which the upper side and the lower side are arranged in parallel, and the length of the lower side is greater than that of the upper side. The outer end of the lower side plate has a grounding lead connecting plate 13, and a lead connecting hole is arranged on the grounding lead connecting plate 13.

[0030] The fixing member 11 of this embodiment is spliced by L-shaped members and horizon...

Embodiment 2

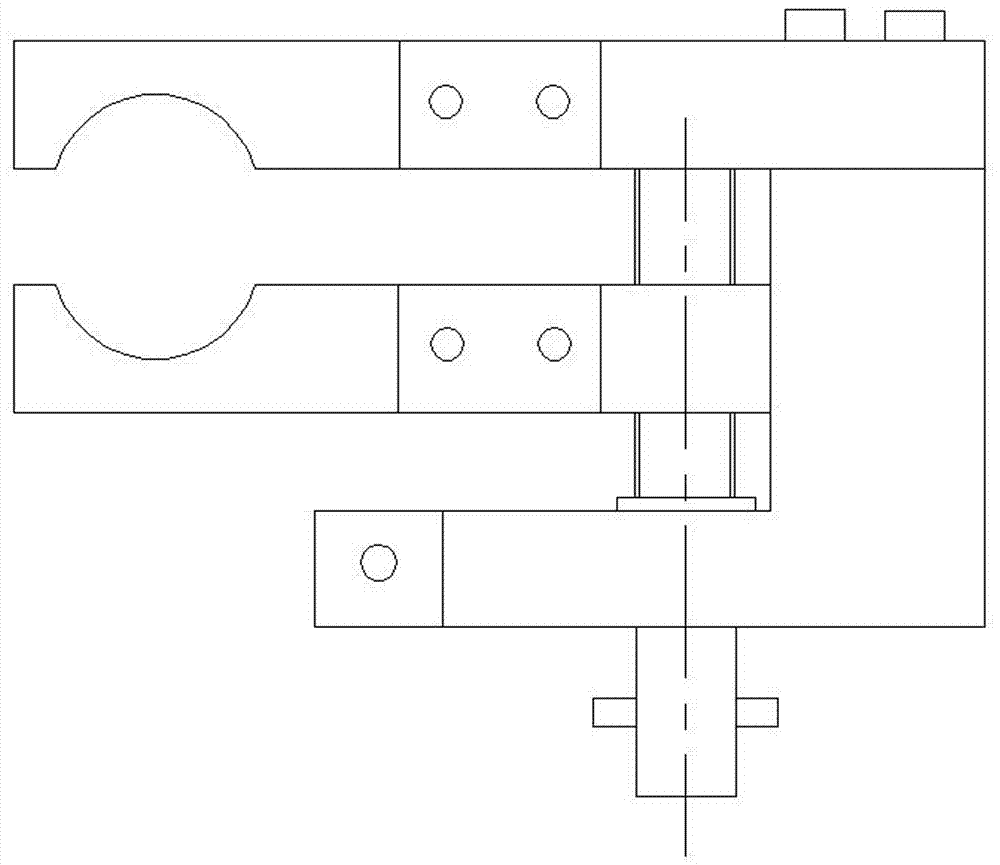

[0038] Embodiment two, such as Figure 4 , Figure 5 As shown, the clamp body of this embodiment is installed longitudinally (the clamp body and the wire are arranged in the same direction), and the clamping mold clamps the wire from the left and right sides of the wire.

[0039] The fixed member of the clamp body in this embodiment has the same structure as that of the first embodiment, but the movable member is a movable beam 12A arranged parallel to the upper side plate of the fixed member.

[0040] Both sides of the upper side plate of the fixed member 11 in the width direction are symmetrically connected with an upper connecting plate 16, and the movable beam 12A includes a middle section 12A1 connected with the screw rod 2 and the fixed member 11 and a lower connecting plate 12A2 symmetrically arranged on both sides of the middle section in the width direction. , the upper connecting plate 16 and the lower connecting plate 12A2 are arranged in parallel, corresponding to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com