Cavity filter and its connector

A cavity filter and connector technology, applied in the direction of connection, conductive connection, waveguide devices, etc., can solve the problems of low intermodulation pass rate, intermodulation jump, intermodulation instability, etc., to reduce intermodulation The risk of instability, the effect of reducing intermodulation jumps and improving intermodulation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below by means of drawings and embodiments.

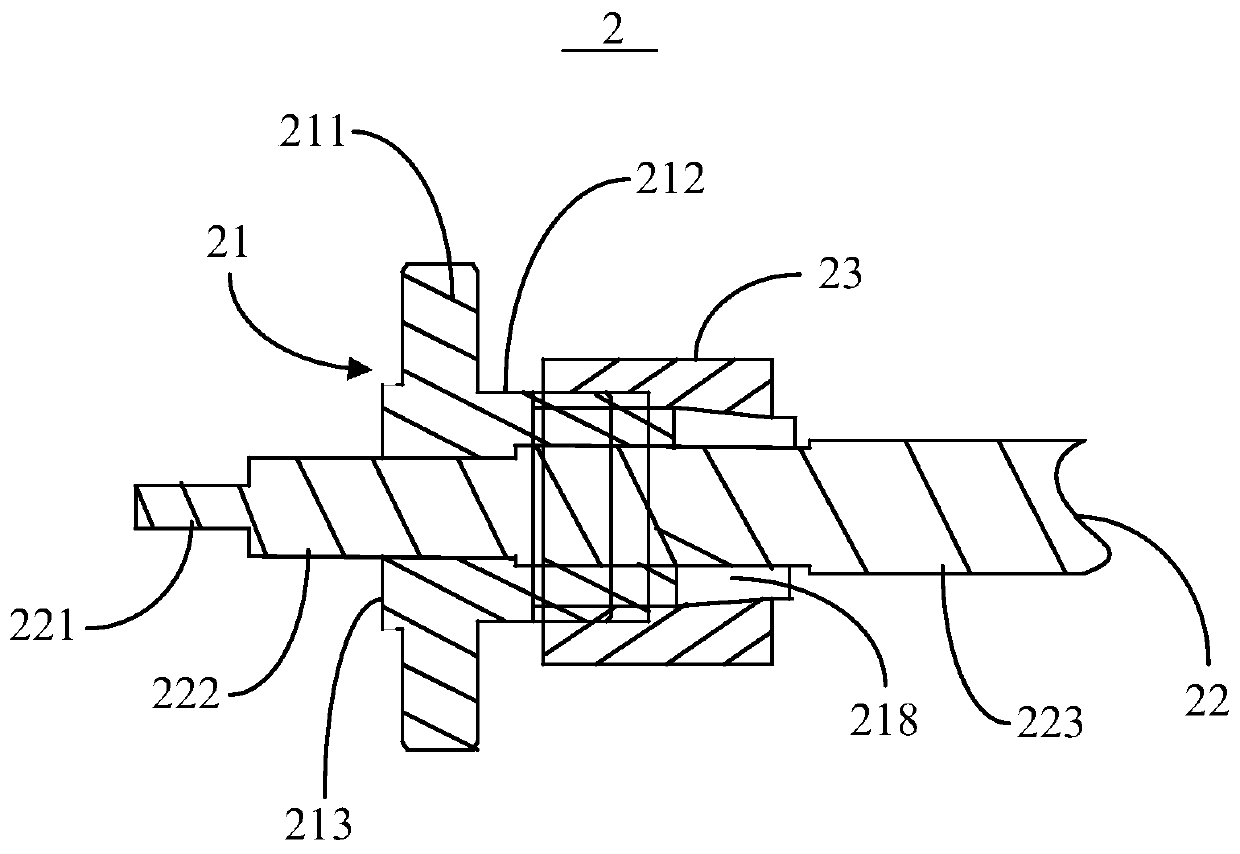

[0028] refer to figure 2 , figure 2 is a schematic cross-sectional view of a connector of a preferred embodiment of the present invention. In this embodiment, the connector 2 includes a ground block 21 , a coaxial cable 22 and a fastener 23 .

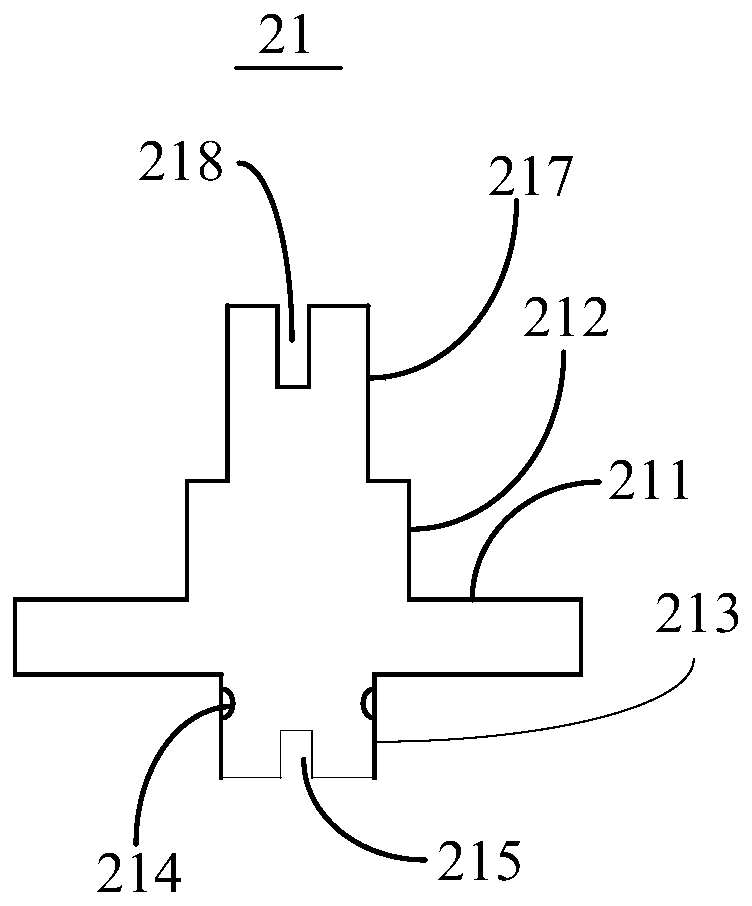

[0029] see further image 3 and Figure 4 , image 3 yes figure 2 Schematic side view of the ground block in, Figure 4 yes figure 2 A schematic top view of the ground block in . The center of the grounding block 21 is provided with a through hole 219 for inserting the coaxial cable 22 . A welding portion 213 , a flange portion 211 , a connecting portion 212 and a clamping portion 217 are sequentially provided on the outer periphery of the ground block 21 in the axial direction. One end of the flange portion 211 is connected to the connecting portion 212 , and the other end is connected to the welding portion 213 . One e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com