Fixing device and fixing method of oxygen generator molecular sieve

A fixing device and molecular sieve technology, which is applied in the field of molecular sieve fixing devices, can solve the problems that molecular sieves affect the oxygen production efficiency and service life of oxygen generators, affect the safety of oxygen use for patients in wards, and lose the function of gas filters, so as to reduce the occurrence of The possibility of side shifting and the degree of wear, ease of assembly, and the effect of improving compactness and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

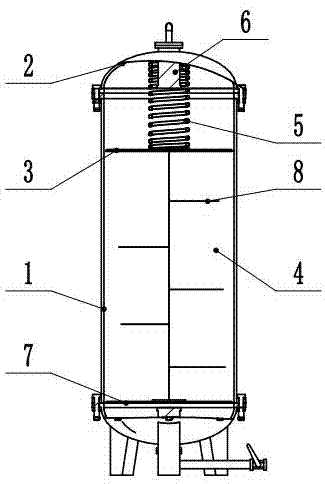

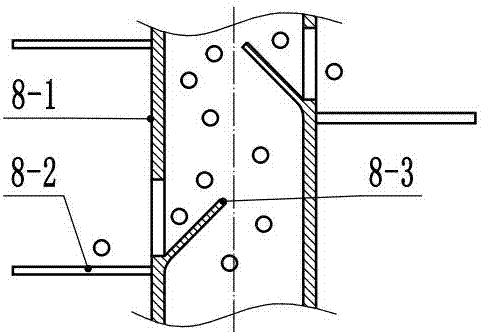

[0021] like figure 1 , a molecular sieve fixing device for an oxygen generator, comprising a cylinder 1 vertically arranged and open at the top, inside the cylinder 1 there are upper and lower filter plates horizontally arranged from top to bottom, and the lower filter plate 7 is opposite to the cylinder body 1 is fixedly installed, and the upper filter plate 3 is movable relative to the cylinder body 1, and the two filter plates and the inner wall of the cylinder body 1 enclose a molecular sieve cavity 4 for containing molecular sieves;

[0022] The oxygen generator molecular sieve fixing device also includes a top cover 2 fixedly installed on the top of the cylinder body 1 and a spring 5 arranged between the top cover 2 and the upper filter plate 3, and the upper end of the spring 5 is in contact with the inside of the top cover 2 , the lower end is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com