High-efficiency composite biogas fermentation catalyst

A biogas fermentation and catalyst technology, applied in fermentation, biochemical equipment and methods, waste fuels, etc., can solve the problems of lack of synergistic promotion measures and improvement of the conversion and utilization efficiency of small molecular compounds of methanogens, so as to be conducive to growth and reproduction. , the effect of promoting decomposition rate and improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

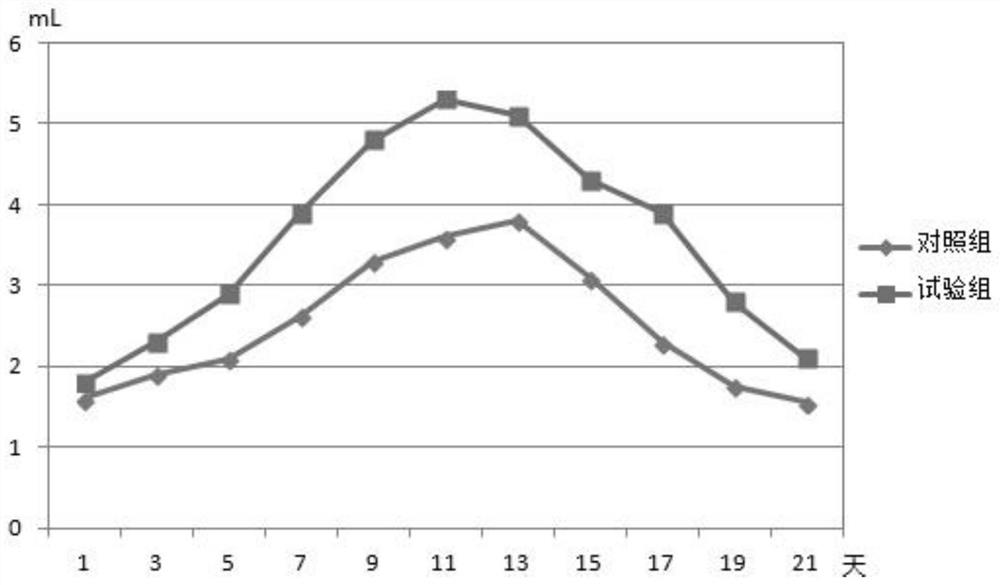

Embodiment 1

[0039] test group:

[0040] Take the purchased Pseudomonas strains and culture them in beef extract peptone medium (add 5.0g peptone, 3.0g beef extract, 5.0gNaCl, 15.0g agar in 1000ml distilled water) for 60-72h at a culture temperature of 28°C. to a concentration of 1x10 9 cfu / ml;

[0041] Take the purchased Bacillus subtilis subsp. subsp. and culture it in beef extract peptone medium (add 5.0g peptone, 3.0g beef extract, 5.0g NaCl, 15.0g agar in 1000ml distilled water) for 60-72h at a culture temperature of 28°C. to a concentration of 1x10 9 cfu / ml;

[0042] Take the purchased Acetobacter pasteurii, add 100g glucose, 10g yeast extract, 20g CaCO to YPD medium (1000ml distilled water 3 , 15g agar, adjust the pH to 6.8) for 80 hours, culture temperature 28 ℃, to a concentration of 1x10 9 cfu / ml;

[0043] Take purchased Saccharomyces cerevisiae and culture it in 5Bé wort agar medium (1.0L 5Bé wort with 15.0g agar added, natural pH) for 75h at a temperature of 28-30°C to a ...

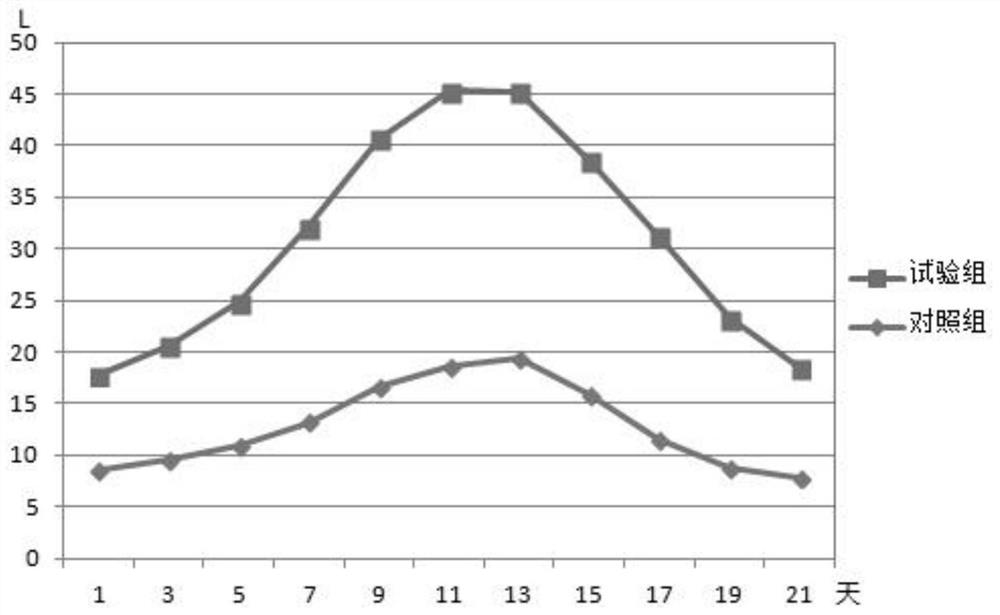

Embodiment 2

[0057] test group:

[0058] Take the purchased Pseudomonas strains and culture them in beef extract peptone medium (add 5.0g peptone, 3.0g beef extract, 5.0gNaCl, 15.0g agar in 1000ml distilled water) for 60-72h at a culture temperature of 28°C. to a concentration of 1x10 9 cfu / ml;

[0059] Take the purchased Bacillus subtilis subsp. subsp. and culture it in beef extract peptone medium (add 5.0g peptone, 3.0g beef extract, 5.0g NaCl, 15.0g agar in 1000ml distilled water) for 60-72h at a culture temperature of 28°C. to a concentration of 1x10 9 cfu / ml;

[0060] Take the purchased Acetobacter pasteurii, add 100g glucose, 10g yeast extract, 20g CaCO to YPD medium (1000ml distilled water 3 , 15g agar, adjust the pH to 6.8) for 80 hours, culture temperature 28 degrees, to a concentration of 1x10 9 cfu / ml;

[0061] Take purchased Saccharomyces cerevisiae and culture it in 5Bé wort agar medium (1.0L 5Bé wort with 15.0g agar added, natural pH) for 75h at a temperature of 28-30°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com