PBL-stiffened CFST joints that can simultaneously improve joint tension and compression properties

A steel tube concrete and stiffening technology, which is applied in the direction of architecture and building structure, can solve the problems of insufficient chord width shear key and support layout space, reduced node bearing capacity, and influence on structural mechanical performance, etc., to achieve Effects of improving material utilization, reducing hot spot stress, and improving tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described in further detail below in conjunction with accompanying drawing:

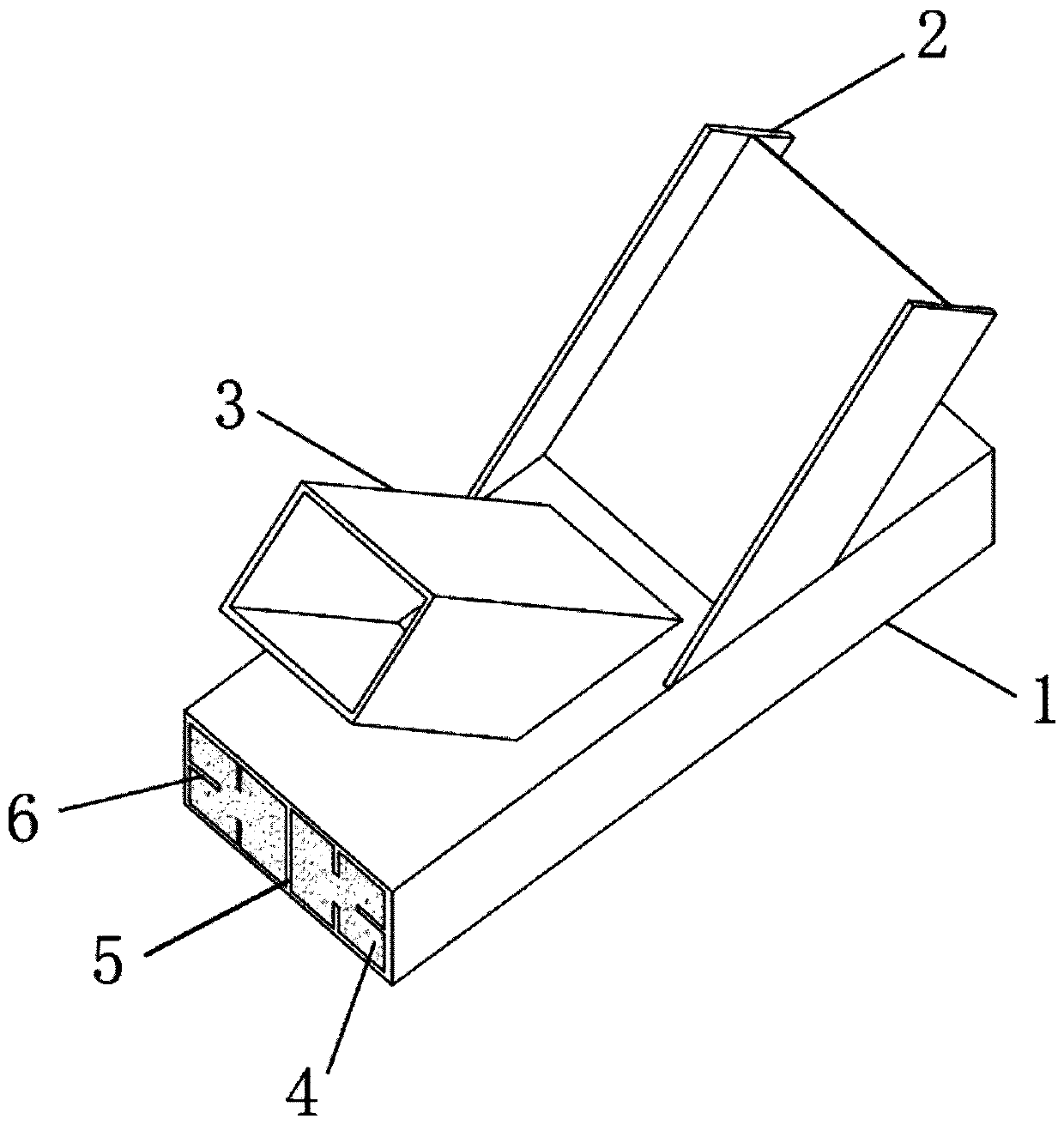

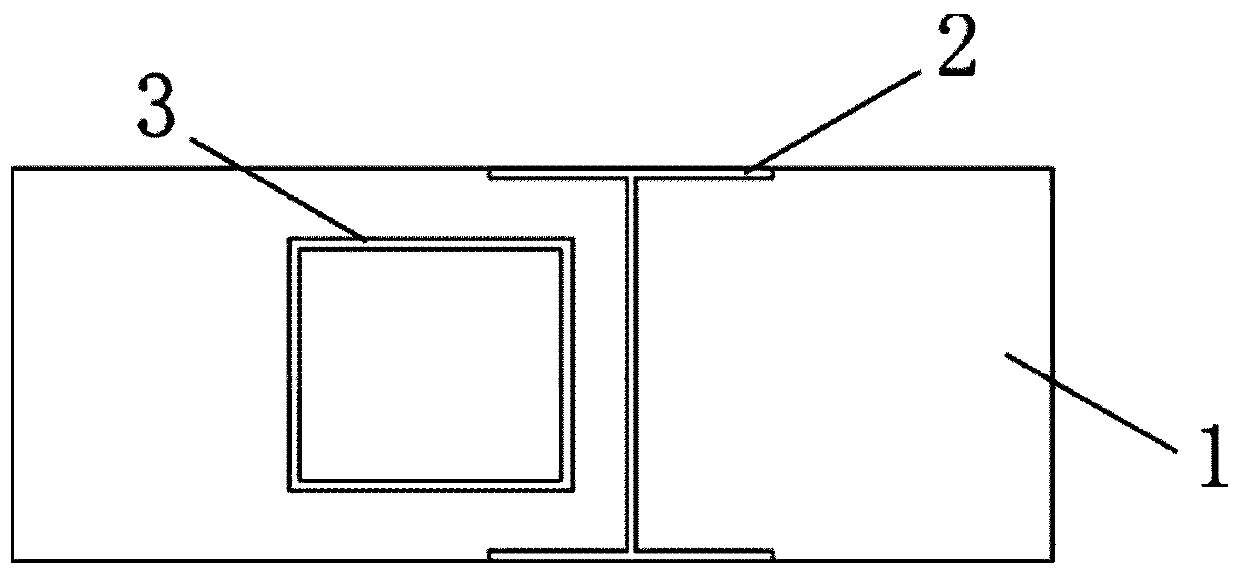

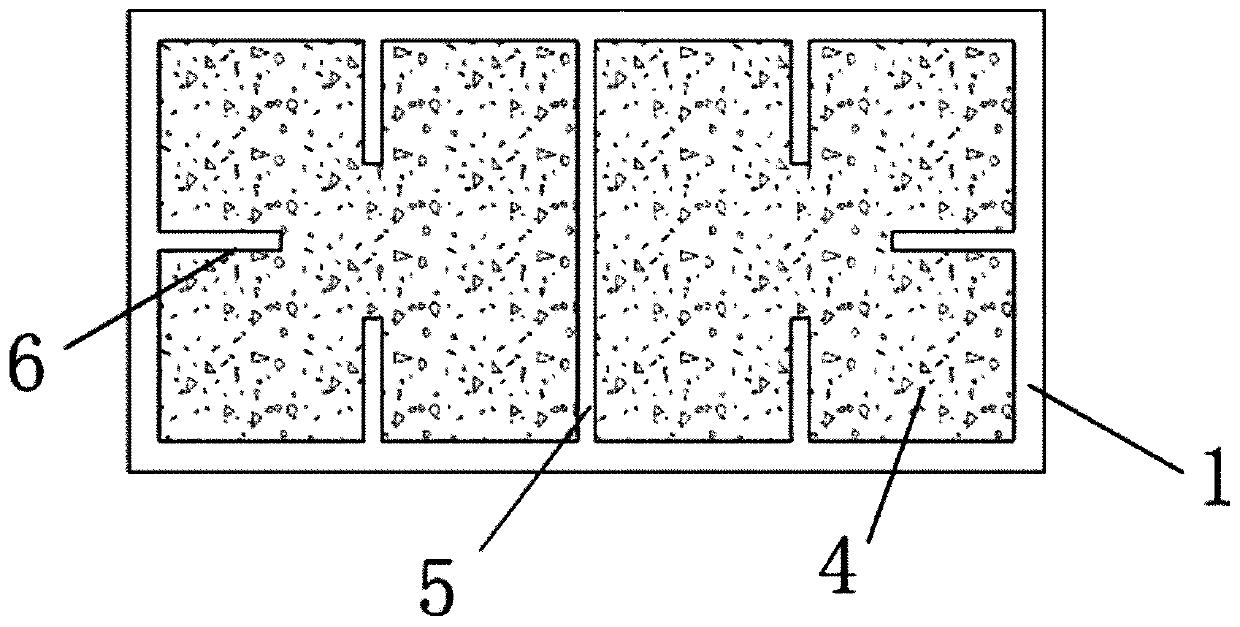

[0034] PBL-stiffened concrete-filled steel tube joints that can improve both tension and compression properties of joints, including chord 1, the top plate of chord 1 is connected with tension web 2 and compression web 3, chord 1, tension web 2 and tension web 3 The overall pressure web 3 is K-shaped, the tension web 2 is steel, the width of the tension web 2 is equal to the width of the chord 1, the axial centerline of the chord 1, and the axial centerline of the tension web 2 It intersects with the axial centerline of the compression web 3; the aspect ratio of the chord 1 is greater than or equal to 2, and the chord 1 is filled with concrete 4.

[0035] It should be noted that in traditional K-type joints, the axial centerline of the tension web, the axial centerline of the compression web and the axial centerline of the chord cannot intersect at One point leads to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com