Optical engine driving belt tightening device

A technology of optical engine and tensioning device, applied in transmission device, mechanical equipment, belt/chain/gear and other directions, can solve the problem of inconvenient installation of tensioning mechanism, achieve simple processing and installation of mechanical structure, meet frequent disassembly and assembly, The effect of quick disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The principle and structure of the present invention will be further described below in conjunction with the accompanying drawings and through embodiments.

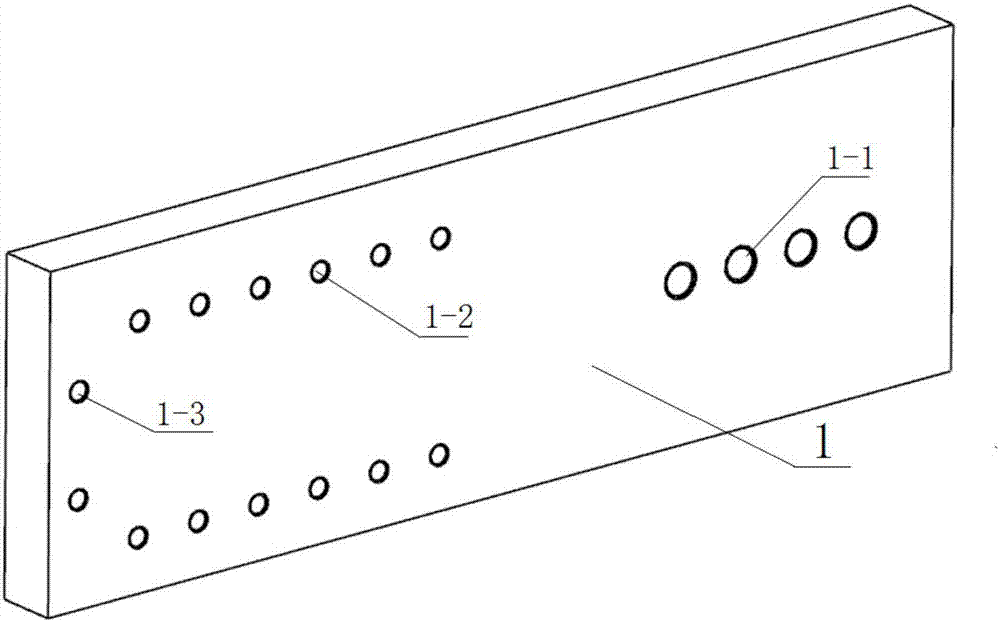

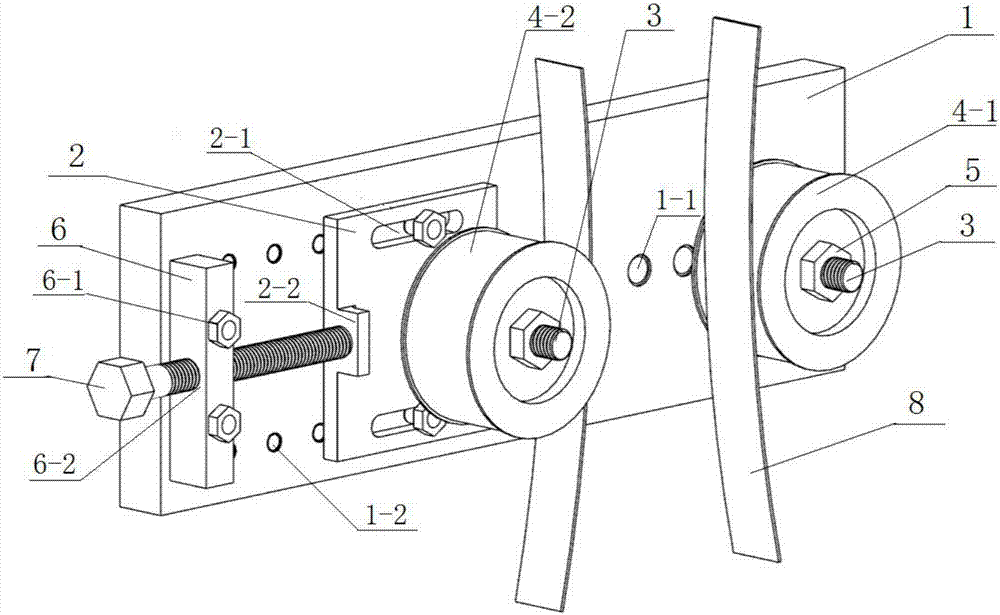

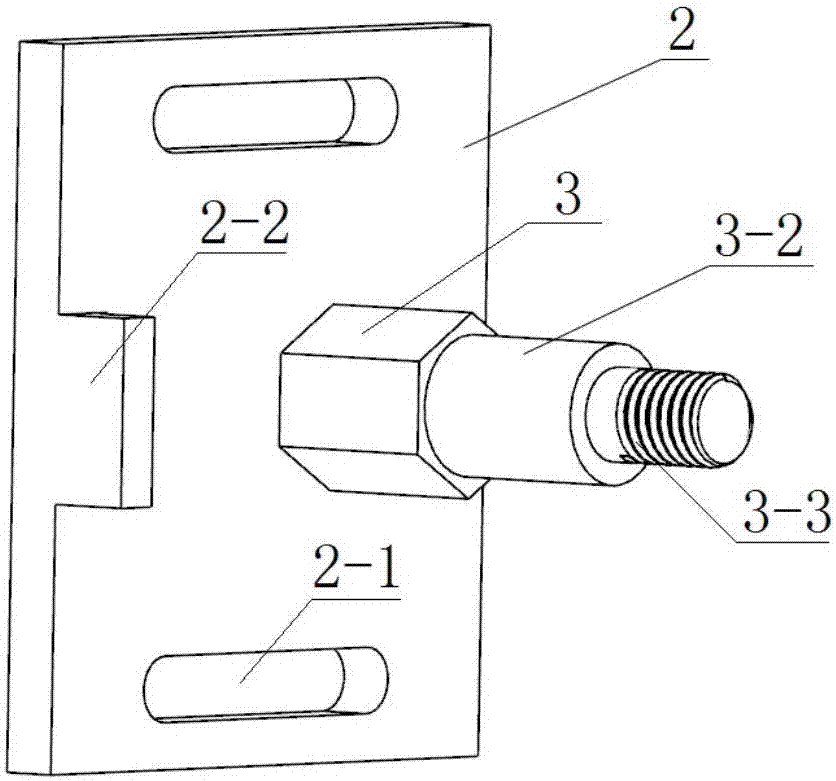

[0016] Optical motor toothed belt tensioning device, its structure is: the right side of mounting plate 1 is provided with first mounting hole 1-1; The left side of mounting hole is provided with the 3rd mounting hole 1-3 (as figure 1 ). The mobile plate 2 is respectively provided with elongated holes 2-1 up and down, the position in the middle is provided with threaded holes 2-3, and the position perpendicular to the elongated holes of the mobile plate is provided with a boss 2-2. The bolts pass through the long holes, and then the mobile plate is pre-tightened and fixed on the second mounting hole (such as image 3 ). The long thread section 3-1 of an idler shaft bolt 3 is screwed into the first mounting hole, the right idler wheel 4-1 is installed on the idler shaft section 3-2, and the lock nut 5 is screwed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com