Touch substrate, fabrication process of touch substrate, display panel and apparatus

A touch substrate and display panel technology, applied in optics, instruments, electrical digital data processing, etc., can solve the problem of low product integration, and achieve the effect of reducing production costs and improving product integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

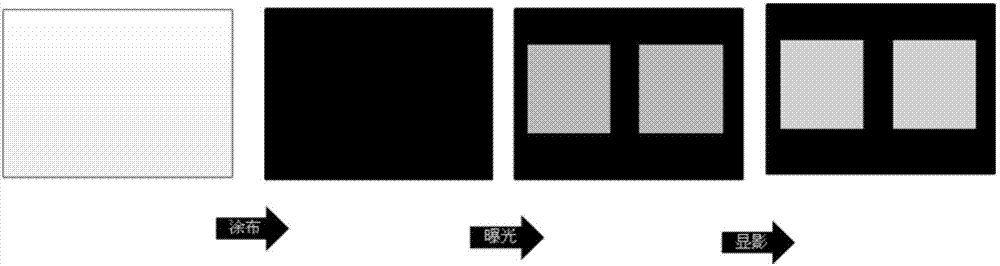

[0040] The embodiment of the present application provides a touch substrate and its manufacturing process, a display panel and a device, which are used to integrate the touch electrode layer on the touch substrate, and ensure that the display screen is not affected, improve product integration, simplify the manufacturing process, and save Production costs, improve production efficiency.

[0041] A detailed introduction of the technical solutions provided by the embodiments of the present application is given below.

[0042] A touch substrate provided by an embodiment of the present application may be, for example, a color filter substrate, including a substrate and a black matrix arranged on the substrate, and also includes a touch electrode layer, and the touch electrode layer is arranged on an adjacent black matrix. between, and the pattern of the touch electrode layer and the black matrix is complementary (here, complementary means that the orthographic projection of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com