Separation and preparation method of chicken meat umami peptide

A technology for umami peptides and chicken, which is applied in the field of separation and preparation of umami peptides from chicken, can solve the problems of human body injury, damage to human body functions, incorrect use methods, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

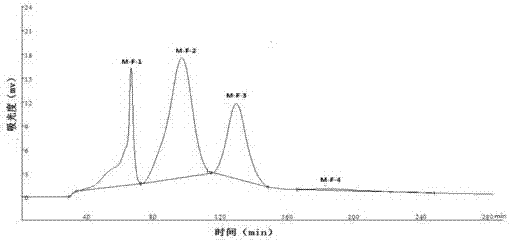

[0028] The preparation method of the umami peptide component of the chicken enzymatic hydrolyzate comprises the following steps:

[0029] Preparation of enzymatic solution

[0030] Peel the fresh three-yellow chicken breast meat and cut it into slices of about 3cm, put it into a meat grinder and grind it into meat filling, add water according to the meat-water mass ratio of 1.5:1, stir in a water bath, and add 0.1% when the temperature reaches 54°C Carry out enzymatic hydrolysis with animal protease, enzymatic hydrolysis for 1.5 hours, add 0.25% neutral protease under the condition of inactivating enzyme, and enzymatic hydrolysis for 2.5 hours. spare.

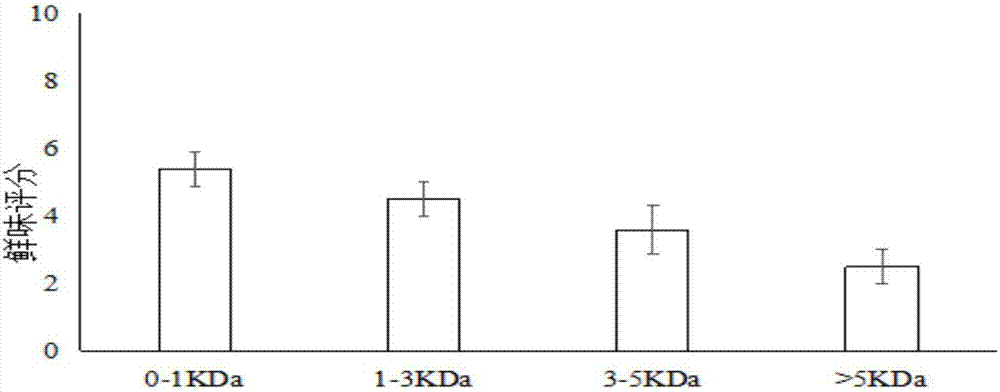

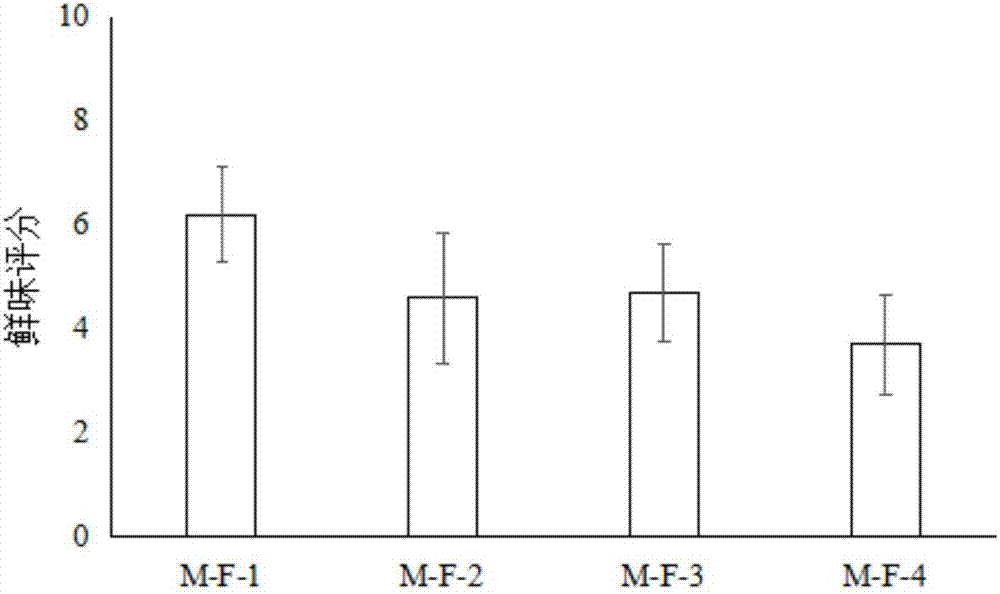

[0031] Preparation of umami peptide fraction

[0032] Centrifuge the enzymatic solution at 5000r / min for 10min at 4°C, take the supernatant, and then perform ultrafiltration on the supernatant according to 5KDa, 3KDa and 1KDa to obtain 5KDa The 4 components were freeze-dried. Its sensory evaluation afterwards (choose 10 per...

Embodiment 2

[0039] The preparation method of the umami peptide component of the chicken enzymatic hydrolyzate comprises the following steps:

[0040] Preparation of enzymatic solution

[0041] Peel the fresh three-yellow chicken breast meat and cut it into slices of about 3cm, put it into a meat grinder and grind it into meat stuffing, add pure water according to the meat-to-water mass ratio of 1.5:1, stir in a water bath, and when the temperature reaches 54°C, add 0.1 Enzymolysis with % animal protease, 1.5 hours of enzymolysis, adding 0.25% neutral protease under constant enzyme, 2.5 hours of enzymolysis, after the end of enzymolysis, quickly raise the temperature to 90°C, maintain 10min to inactivate the enzyme activity, and then collect the enzymolysis liquid for use.

[0042] Preparation of umami peptide fraction

[0043] Centrifuge the enzymatic solution at 5000r / min for 10min at 4°C, take the supernatant, and then perform ultrafiltration on the supernatant according to 5KDa, 3KDa...

Embodiment 3

[0045] The preparation method of the umami peptide component of the chicken enzymatic hydrolyzate comprises the following steps:

[0046] Preparation of enzymatic solution

[0047] Peel the fresh three-yellow chicken breast meat and cut it into slices of about 3cm, put it into a meat grinder and grind it into meat stuffing, add pure water according to the meat-to-water mass ratio of 1.5:1, stir in a water bath, and when the temperature reaches 54°C, add 0.1 Enzymolysis with % animal protease, 1.5 hours of enzymolysis, adding 0.25% neutral protease under constant enzyme, 2.5 hours of enzymolysis, after the end of enzymolysis, quickly raise the temperature to 90°C, maintain 10min to inactivate the enzyme activity, and then collect the enzymolysis liquid for use.

[0048] Preparation of umami peptide fraction

[0049] Centrifuge the enzymatic solution at 5000r / min for 10min at 4°C, take the supernatant, and then perform ultrafiltration on the supernatant according to 5KDa, 3KDa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com