Detaching device for rotating shaft of steel casing motor with clamping function

A technology for motor shafts and dismantling devices, applied to workpiece clamping devices, hand-held tools, manufacturing tools, etc., can solve the problems of reducing the secondary utilization rate of the shaft, scrapping the rotor, and easy relative displacement, etc., to avoid excessive shaft head It is difficult to insert the bearing, prevent the shaft head from becoming larger or the shaft is damaged, and improve the effect of secondary reuse rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical scheme of this patent is described in further detail below in conjunction with specific embodiments

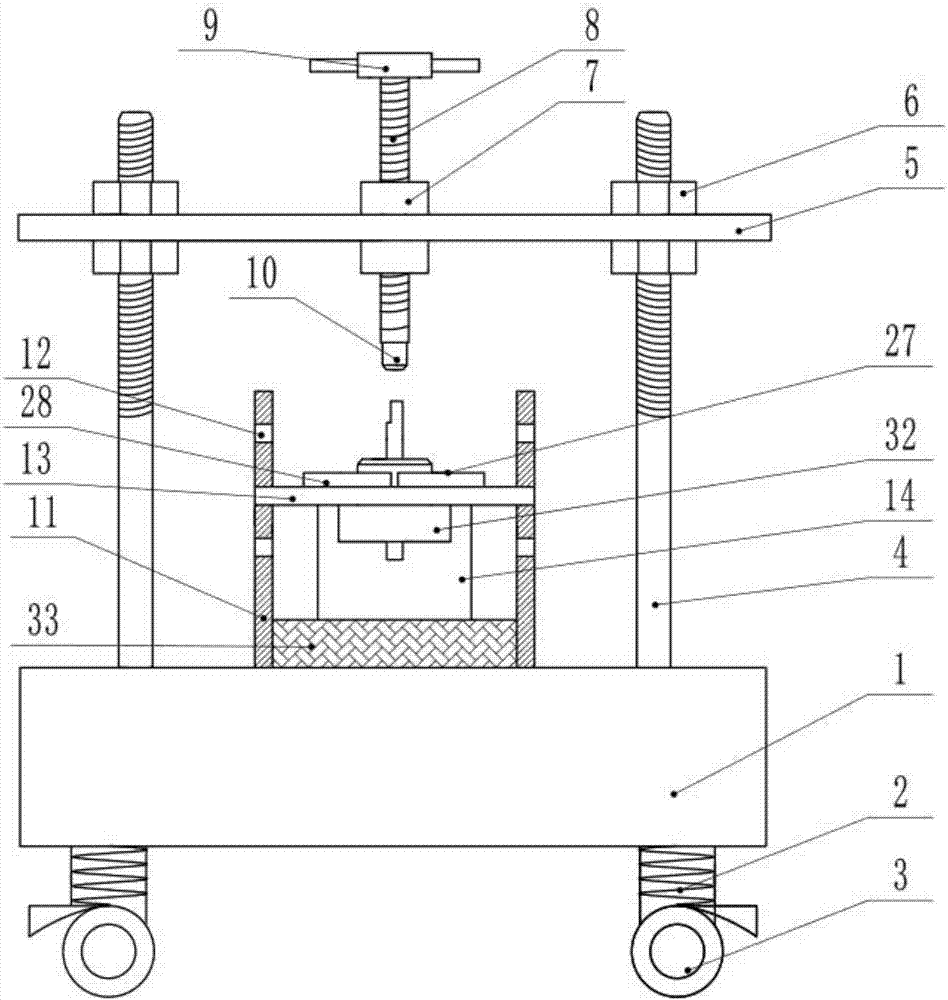

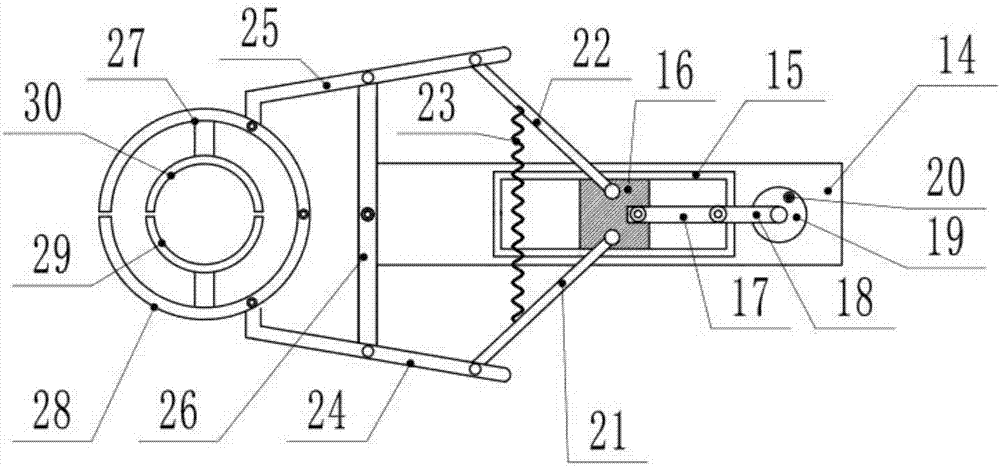

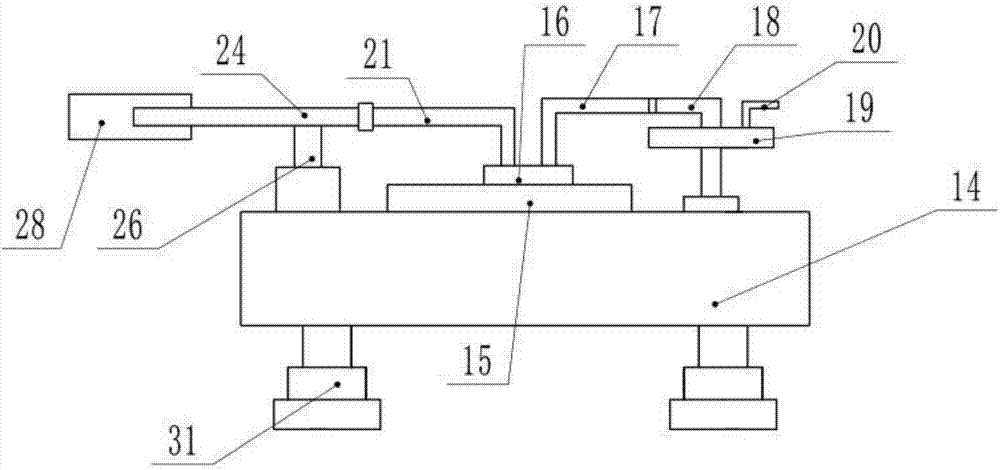

[0021] see Figure 1-4 , an iron shell motor shaft removal device with a clamping function, including a machine 1, an adjusting screw 4, a support plate 5, a screw 8, a rotating handle 9, an extrusion head 10, a dismounting table 11, a limit groove 12, Bearing table 14, slide rail 15, positive clamping hand 29, auxiliary clamping hand 30, oiling device 32 and sponge 33, described machine table 1 lower side is fixedly installed shock-absorbing leg 2, and shock-absorbing leg 2 is provided with at least four groups, A universal wheel 3 is fixedly installed under the vibration support foot 2, and a limit locking device is installed on the universal wheel 2 to prevent the device from moving during work; Set four groups, the upper and lower parts of the adjusting screw 4 are tapped with threads, the adjusting screw 4 is fixedly connected with the machine table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com