Permanent magnet bearing

A permanent magnet bearing and permanent magnet technology, applied in the field of mechanical parts, can solve the problems of self-compensation and poor impact resistance of permanent magnet bearings, and achieve the effect of improving reliability and overcoming the damage of permanent magnet bearings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

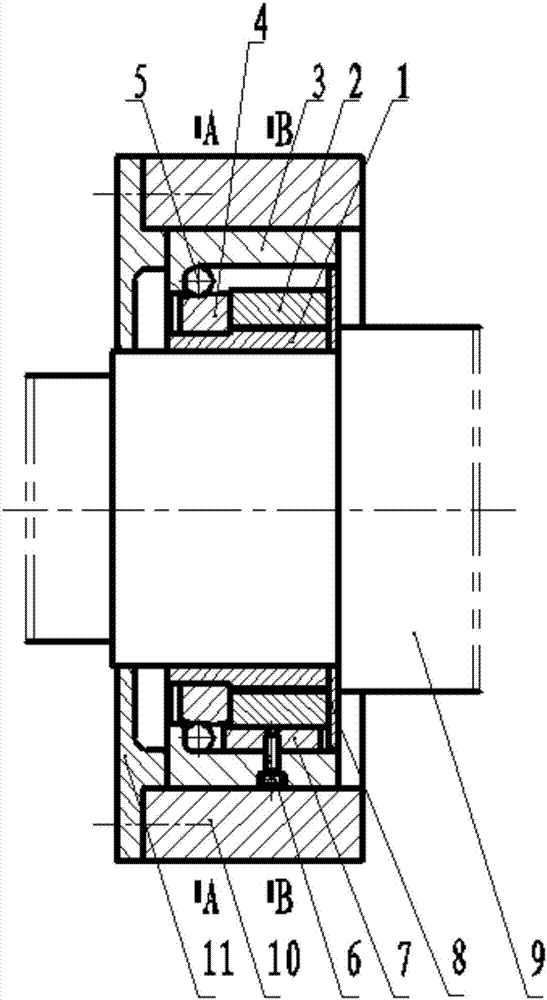

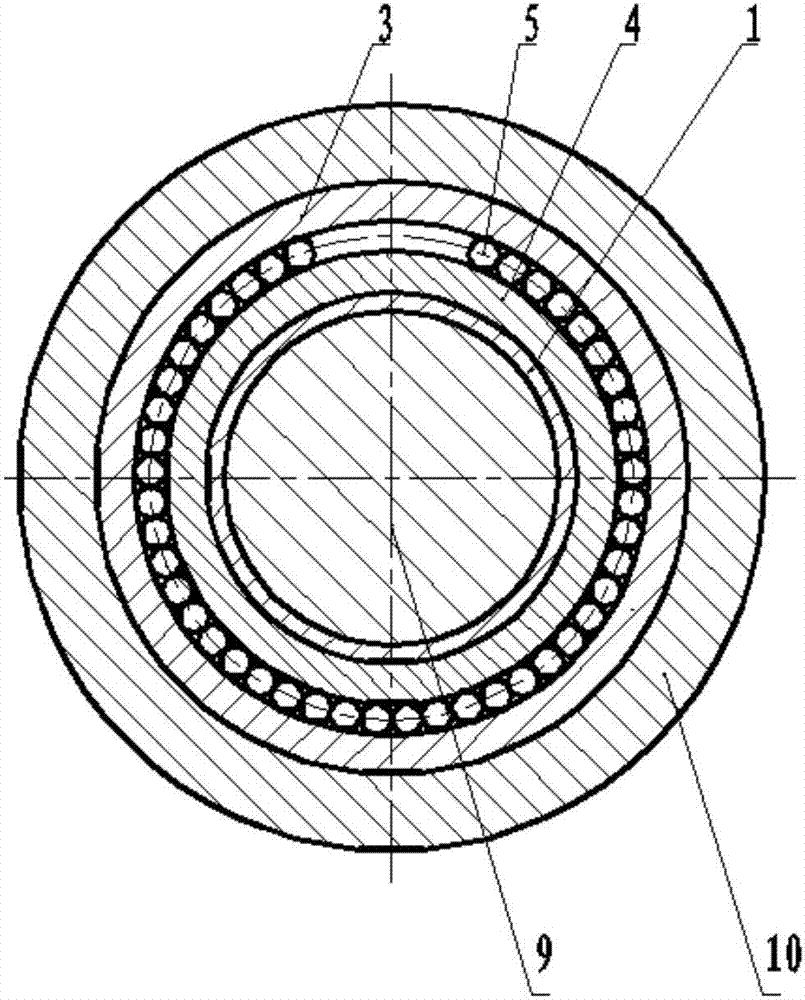

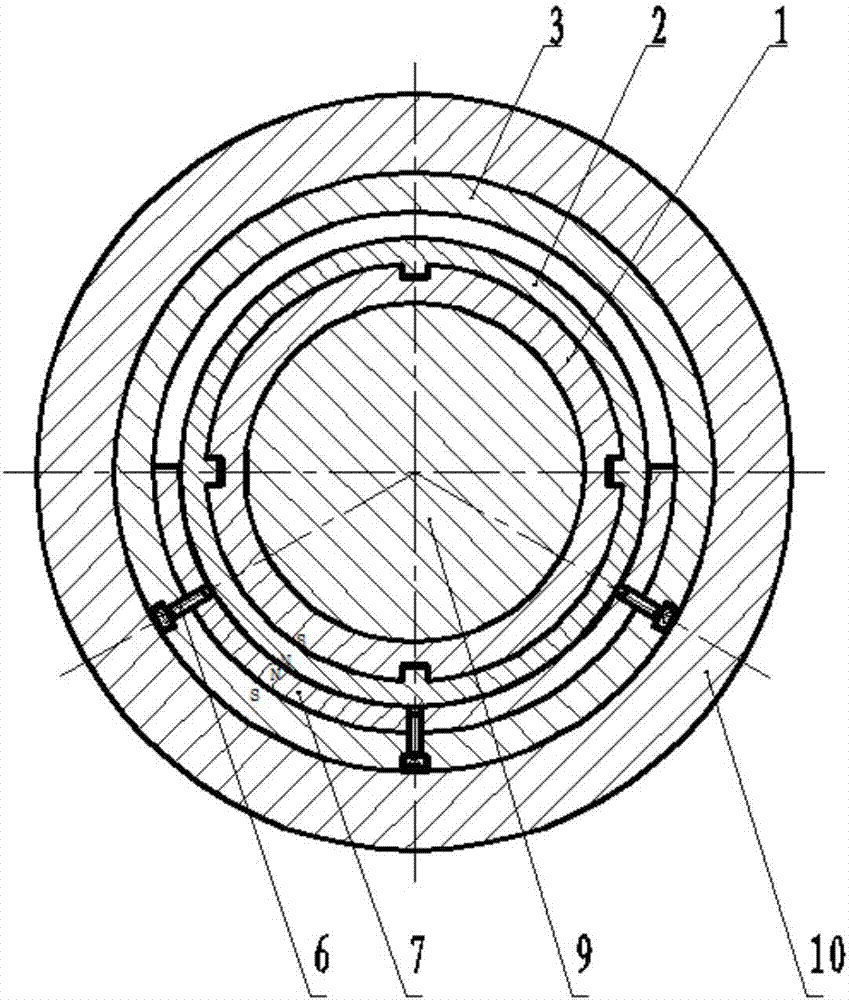

[0027] Such as figure 1 As shown, a permanent magnetic bearing is composed of a running assembly and a stationary assembly. The moving assembly is composed of a bearing inner ring 1, an inner ring permanent magnet 2, a bearing ring 4, a ball 5, and a retaining ring 8. The described The static assembly is composed of bearing outer ring 3, outer ring permanent magnet 7, and cylindrical head screw 6. Cooperate with the common parts of the bearing system, the rotating shaft 9, the bearing seat 10 and the gland 11 to form the bearing system.

[0028] The focus of the present invention lies in the matching design of the bearing ring 4 and the ball 5, so that it has impact resistance, self-protection and self-compensation.

[0029] Since the retaining ring 8 is consistent with the inner diameter of the bearing inner ring 1, it is installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com