High-speed planetary reducer used for new energy automobiles

A planetary reducer, new energy vehicle technology, applied in transmission parts, gear transmissions, belts/chains/gears, etc., can solve the problems of small transmission torque, cumbersome structure, low transmission efficiency, etc., and achieve low transmission temperature rise. , The effect of wide speed ratio range and large torque output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

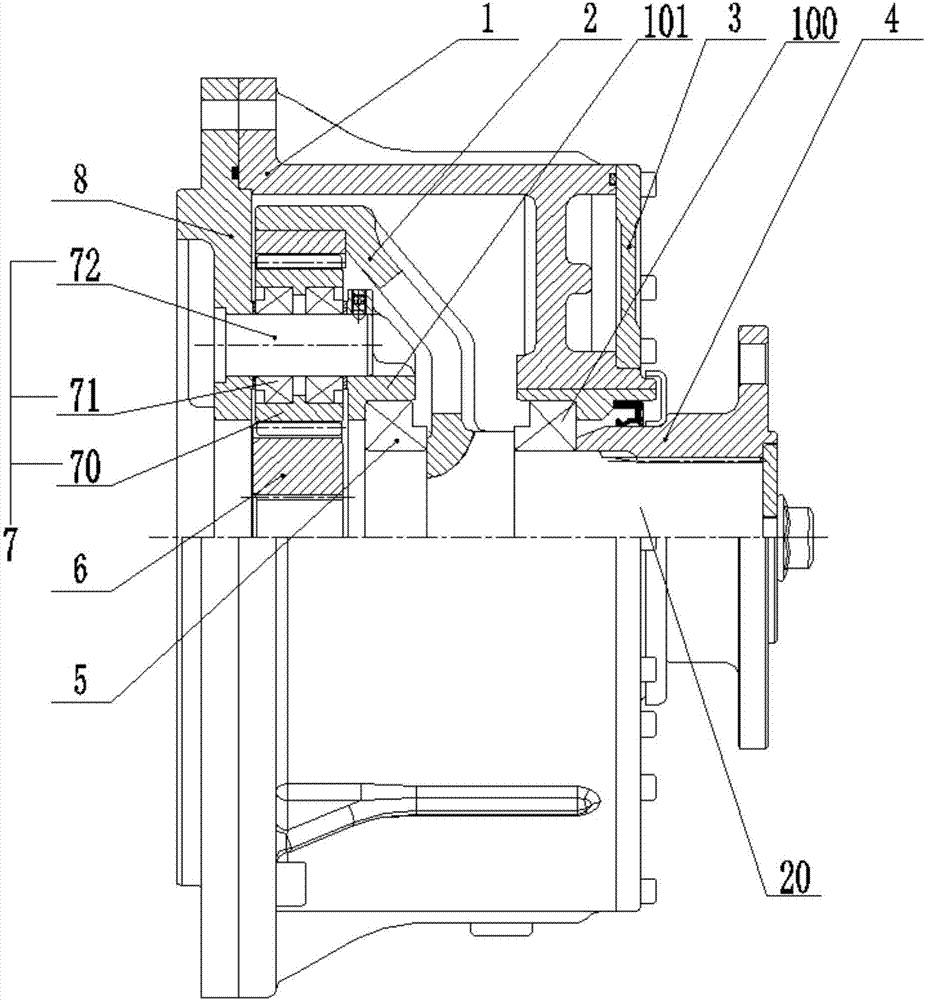

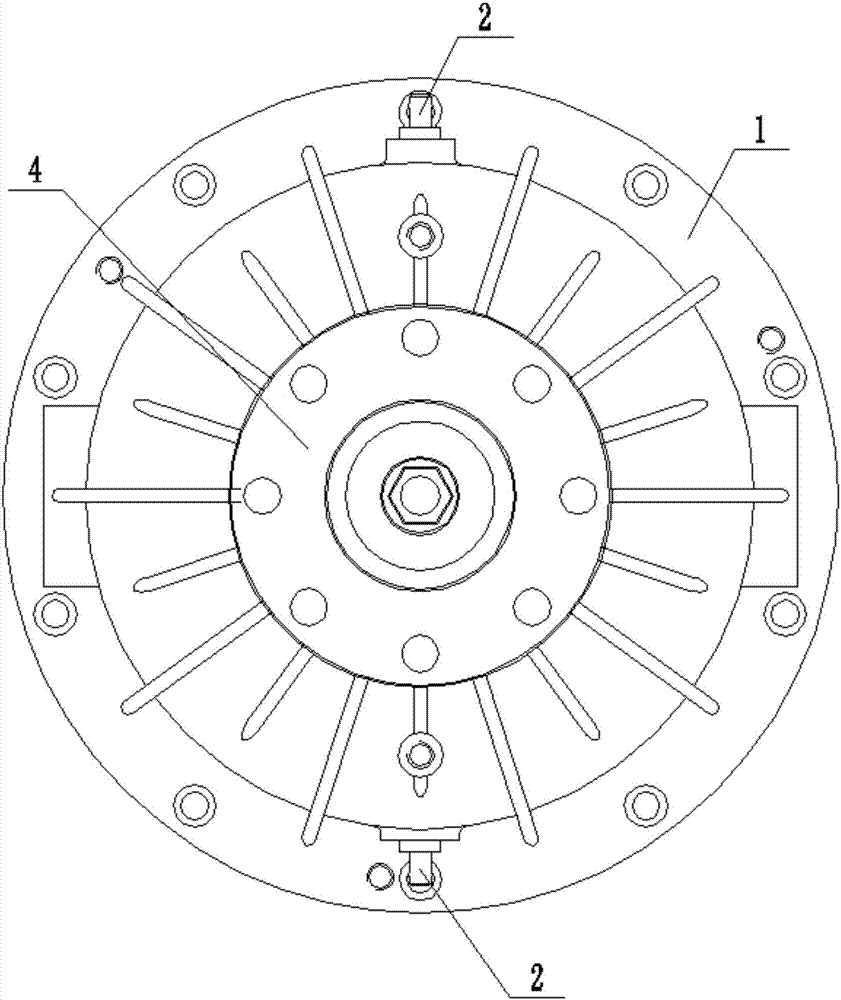

[0022] Such as figure 1 with figure 2 As shown, a high-speed planetary reducer for a new energy vehicle of this embodiment is characterized by comprising: reducer housing 1, output ring gear 2, output flange 4, sun gear 6, planetary gear set 7 and planetary gear The planet carrier 8 is fixedly connected to the reducer housing 1 by bolts, the output ring gear 2 is fixedly connected to the output shaft 20, and the output shaft 20 is connected to the reducer housing through the first bearing 100 1 Rotation connection, the output flange 4 is keyed to the output shaft 20, the planetary gear set 7 includes a planet gear 70, a second bearing 71 and a shaft 72, the shaft 72 is connected to the planet carrier 8, the planet The gear 70 is rotatably connected with the shaft 72 through the second bearing 71 and meshes with the output ring gear 2, and the sun gear 6 meshes with the planetary gear 70.

[0023] Preferably, at least three planetary gear sets 7 are evenly arranged around the sun...

Embodiment 2

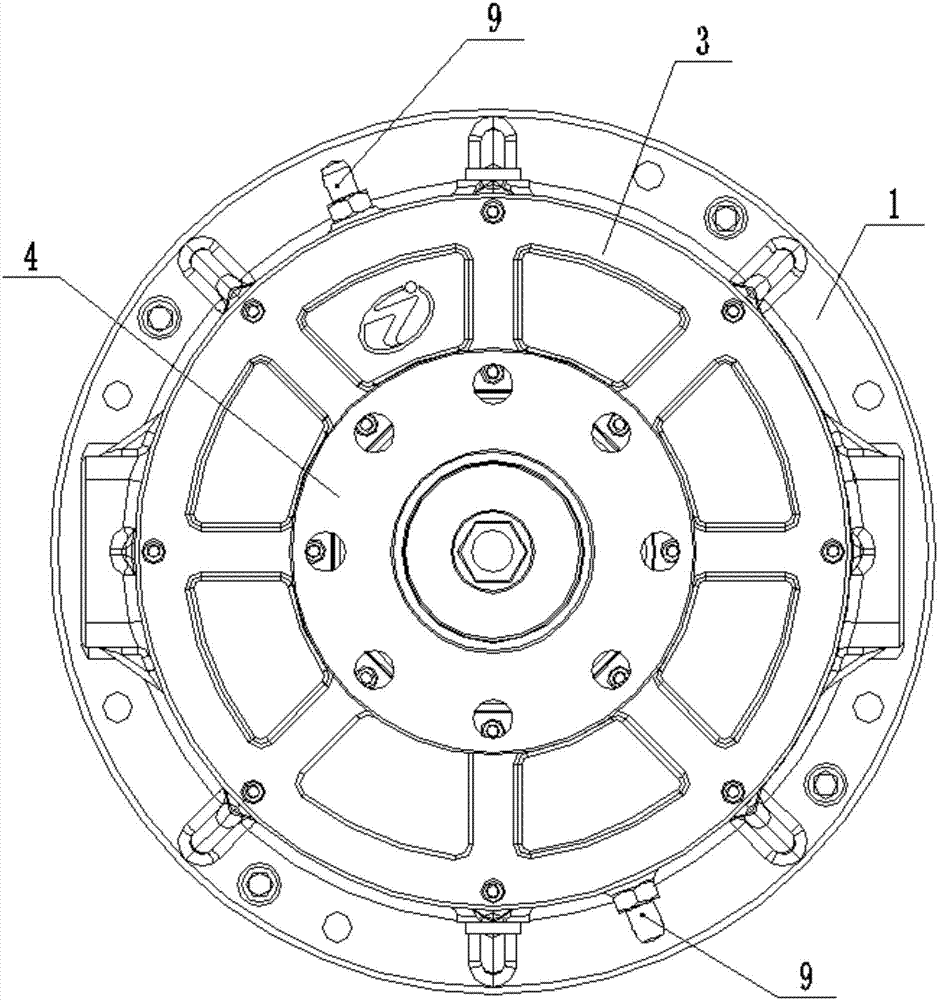

[0027] image 3 with Figure 4 As shown, a high-speed planetary reducer for a new energy vehicle is characterized by comprising: an inner ring gear seat 3, a reducer housing 1, an output flange 4, a planetary gear set 7, a planet carrier 8, a sun gear 9 and The inner gear 11, the inner gear seat 3 is fixedly connected to the reducer housing 1 by bolts, the inner gear 11 is fixed on the inner side of the inner gear seat 3, and the planet carrier 8 is opposite to the output shaft 20 In a fixed connection, the output shaft 20 is rotatably connected to the reducer housing 1 through a first bearing 100, the output flange 4 is keyed to the output shaft 20, and the planetary gear set 7 is mainly composed of a shaft 70 and a second bearing 71 It is composed of a planetary gear 72, the shaft 70 is connected to the planet carrier 8, the planetary gear 72 is rotatably connected to the shaft 70 through a second bearing 71, the planetary gear 72 meshes with the ring gear 11, the sun gear T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com