Practical ice crusher

An ice crushing machine, a practical technology, applied in applications, making ice, household appliances, etc., can solve problems such as low stability, high use cost, and increased chance of contamination, so as to improve food safety and uniformity , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

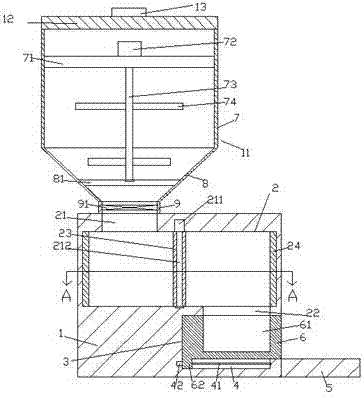

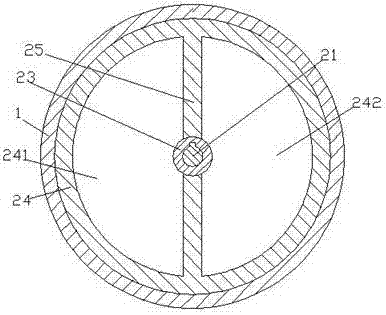

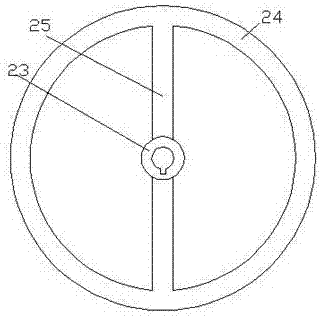

[0022] Such as Figure 1-Figure 7 As shown, a practical ice crusher of the present invention includes a base body 1 and a bucket box 11 arranged above the base body 1, the top cover of the bucket box 11 is provided with an end cover 12, and the end cover 12 is provided with a pull ring 13 on the top, and the bucket box 11 includes a first bucket-shaped part 7, a second bucket-shaped part 8 arranged at the bottom of the first bucket-shaped part 7, and a The third bucket-shaped part 9 at the bottom, the inside of the seat body 1 is provided with a first cavity 2, and the top of the left side of the first cavity 2 is provided with a first port 21 communicating with the third bucket-shaped part 9 , the bottom of the right side of the first cavity 2 is provided with a second port 22, the seat 1 at the bottom of the second port 22 is provided with a second cavity 3, and the bottom of the second cavity 3 is provided with a second port 22. The seat body 1 is provided with a sliding g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com